An interdisciplinary team of researchers from Korea, Australia, Great Britain, and Germany – with the participation of the Leibniz Institute of Photonic Technology (Leibniz IPHT) – were able to, for the first time, optimize an optical glass fiber in such a way that light of different wavelengths can be focused extremely precisely. This level of accuracy was achieved by 3D nanoprinting an optical lens, which was applied to the end of the fiber. This opens up new possibilities for applications in microscopy and endoscopy as well as in laser therapy and sensor technology.

Lenses at the end faces of optical fibers currently used in endoscopy for medical diagnostics have the disadvantage of chromatic aberration. This imaging error of optics (caused by the fact that light of different wavelengths, ie. different spectral colors, is shaped and refracted differently) leads to a shift in the focal point and thus to blurring in imaging over a wide range of wavelengths. Achromatic lenses, which can minimize these optical aberrations, offer a solution to this.

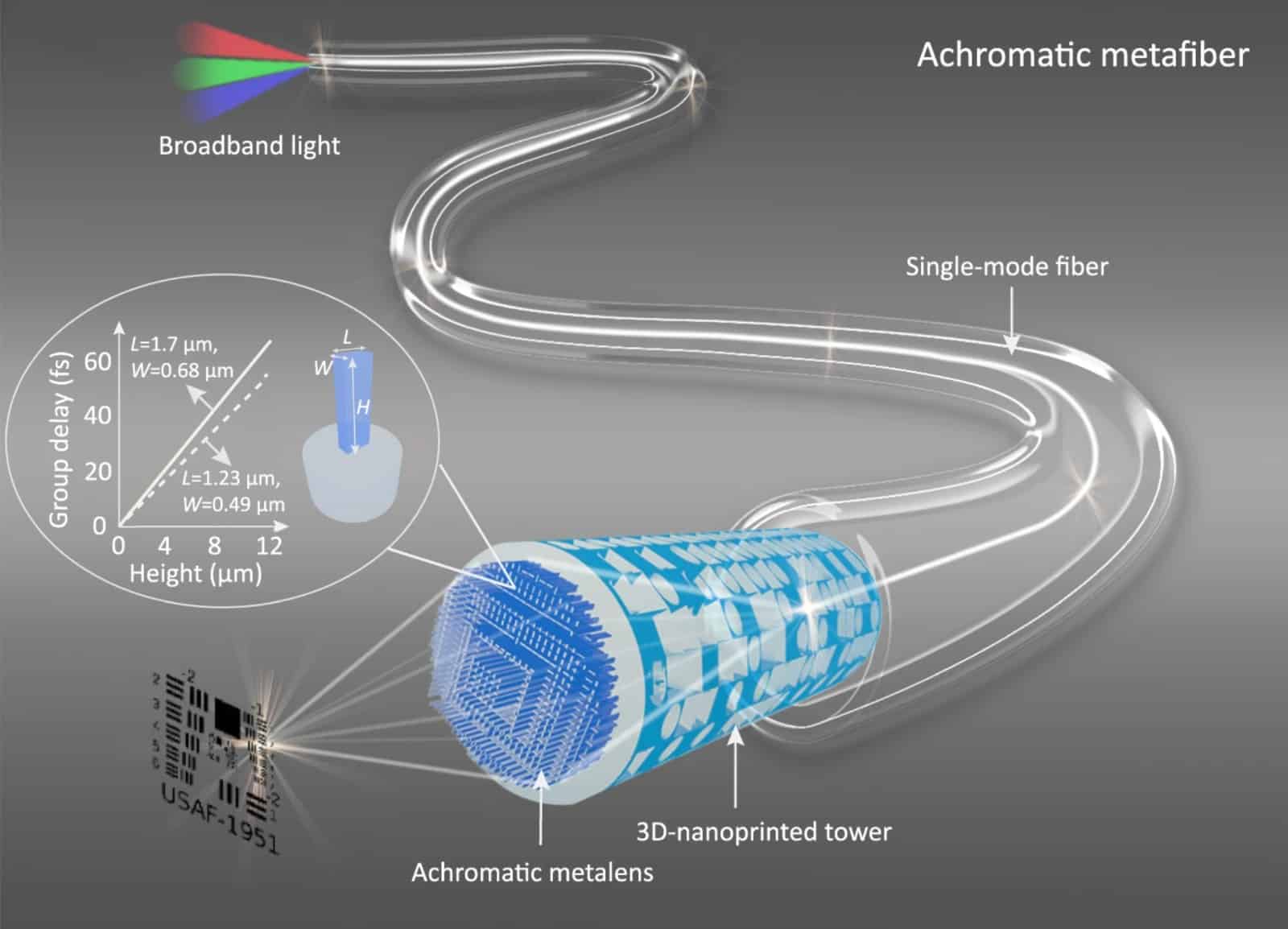

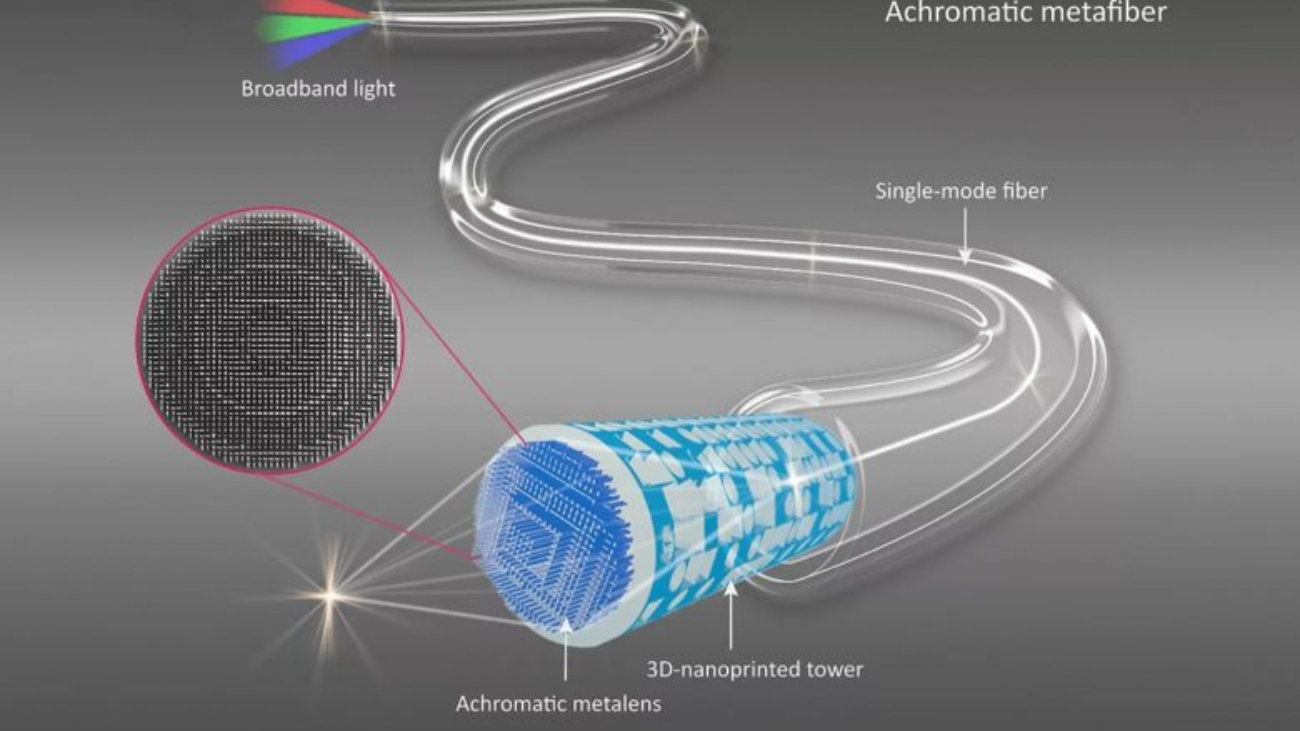

Such an achromatic lens, a so-called meta lens, which is attached to the end of an optical fiber and allows focusing and imaging of minute details with depth-of-field imaging, has now been realized, for the first time, by the international team. “For ideal light shaping and achromatic focusing, we realized an ultra-thin polymer-based lens, which consists of a complex design of geometric structures in the form of nanopillars. This structure was printed directly on the tip of a 3D printed hollow tower structure on one of the end faces of a commercial optical fiber. In this way, optical fibers can be functionalized in such a way that light can be focused very efficiently on a focal point and images with high resolution can be generated,“ explained Prof. Dr. Markus Schmidt, head of the Fiber Photonics Department at Leibniz IPHT.

Manufacturing on Demand

In experimental studies, the researchers were able to demonstrate the lens and focusing efficiency of the developed fiber optics using fiber-based confocal scanning imaging as an example: Using a fiber with achromatic meta-optics, the team achieved convincing image quality with high image acquisition efficiency, and high image contrast at different wavelengths. The focus positions remained almost constant even at different wavelengths.

“Since the developed nanostructured meta lens is extremely small and flat, a fiber optic design with achromatic optics at the top offers the potential to further advance miniaturized and flexible endoscopic imaging systems based on fiber technology and to enable even more gentle minimally invasive examinations,“ said Prof. Dr. Markus Schmidt, when explaining a possible application scenario. In addition to this main area of application, the researchers see further areas of application in the field of laser-assisted therapy and surgery, fiber-optic communication, and fiber sensor technology.

The realized meta lens on the end face of an optical fiber is the result of a joint and international collaboration between researchers from Monash University in Melbourne, Australia, Ludwig-Maximilians-Universität München, Germany, Pohang University of Science and Technology, Korea, University in Jena, Germany, POSCO-POSTECH-RIST Convergence Research Center for Flat Optics and Metaphotonics in Pohang, Korea, Imperial College London, UUK, and Leibniz IPHT.

The researchers published their results in the journal Nature Communications.

You might also like:

Stratasys makes strategic investment in Axial3D: Personalized 3D printed anatomic models are used for pre-surgical planning and diagnostic use to improve patient outcomes while shortening the time spent in the operating room. They are also used in education and training, and medical device development. Creating a 3D printed model from a patient’s scan data normally takes several hours and requires a high level of technical expertise and expensive software licenses. Axial3D’s artificial intelligence-powered algorithms enable healthcare providers to segment CT and MRI scans for these models without significant investments in time, specialized skills and large upfront costs.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment