Materialise, a developer of additive manufacturing software, has invested in Ditto, a manufacturer of online eyewear fitting services, to enable customers to browse customized 3D printable frames through Ditto’s online store. The software can create accurate digital versions of individual faces, so they can try frames online before buying.

Alireza Parandian, head of global business strategy for Materialise’s wearable business, said: “3D printing has the potential to create unique designs, produce in small batches, and provide an unprecedented level of personalization that can change the industry. Our cooperation with Ditto confirms our commitment to create an end-to-end digital platform for the glasses industry.”

Materialize and Ditto’s 3D printed glasses partnership

Materialize is one of the world’s largest 3D printing service providers and software developers. The company uses its stereolithography (SLA), laser sintering (LS), fused deposition modeling (FDM), metal printing (MP), multi-jet fusion (MJF) and PolyJet 3D printing technology to provide software and additive manufacturing services. Materialise’s investment helped Ditto implement a build-to-order system designed to tailor the creation process to the customer’s specific eyewear requirements.

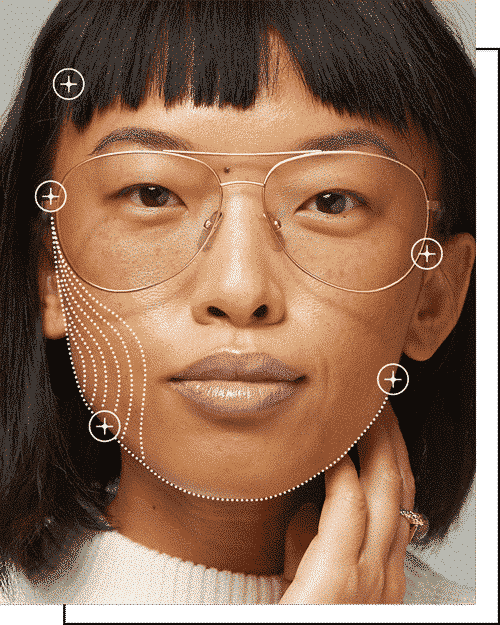

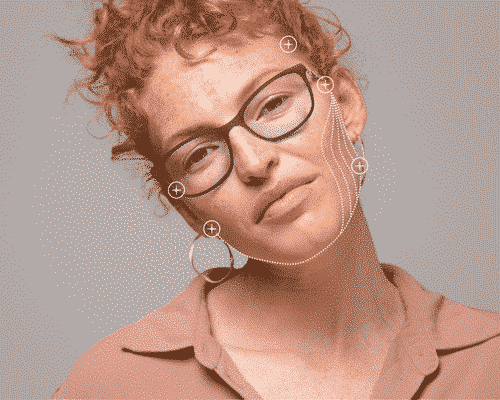

Ditto’s website prompts shoppers to center their faces on the circle. To measure the size of his head, the user touches his forehead with a credit card. The universal size of this card will help the software create a picture of the consumer’s face. After using Ditto’s software to measure the customer’s face, they can freely browse the frames on the website. Through Ditto’s online glasses service, Materialize will be able to provide customized 3D printed frames.

Previously, Materialize cooperated with HOYA to launch a revolutionary vision-centric 3D tailor-made glasses called Yuniku. Before calculating the ideal position of the lens relative to the individual’s eyes, the glasses technology first evaluates the consumer’s visual needs and facial features. Then, create a personalized 3D printing frame based on its facial parameters.

Benefits of 3D printed glasses

Materialise’s 3D printing capabilities reduce the need for high inventory levels, which makes the manufacturing process more sustainable because the frames are produced only according to customer needs. This also means that customers can personalize the framework they want before the manufacturing process begins.

“Our cooperation with Materialize will help us achieve our goal of making glasses more personalized. The transition to e-commerce, digital smart stores and digital manufacturing is inevitable,” said Kate Doerksen, CEO and co-founder of Ditto. “We are happy to bring comprehensive solutions to our customers to create differentiated and personalized customer experiences and products.”

3D printing and cooperation in the field of glasses

3D printing has been implemented in the glasses industry for many years and has led to multiple successful projects. In July 2017, Xiafei enlisted in Materialise to 3D print complex glasses called “wearable sculptures” for the OXYDO capsule series. In 2017, the glasses brand product line was offline, and it had previously cooperated with luxury brands such as Dior and Boss. , Tommy Hilfiger.

In addition to luxury brands, French eyewear brand MOREL began mass production of thousands of frames for the consumer market using the 3D printing service of 3D printing service bureau INITIAL in 2018. MOREL has produced lightweight 3D printed glasses with the help of INITIAL, so that consumers can use this kind of glasses.

In September 2020, Facebook Connect disclosed details of “Project Aria”, which is a prototype of an augmented reality (AR) headset. Facebook is using the project to collect data for Al training and to evaluate public perceptions of the technology. Soon after, Luxexcel, a 3D printed lens expert for prescription glasses, announced its plan to form a new leadership team to study the smart glasses market in depth.