Global medical device company LimaCorporate has confirmed that it has started construction of its forthcoming on-site 3D printing facility at the Hospital for Special Surgery (HSS) in New York. First confirmed in January this year, the partners held a groundbreaking ceremony at the site at the end of May. Building works are scheduled for completion by 2020, and the center itself is expected to be in operation early in the same year.

“HSS and Lima had been working very successfully together on multiple projects under a Master Development Agreement since March 2016,” comments Leonard Achan, Chief Innovation Officer at the Hospital for Special Surgery. “At the same time,” Achan adds, “Lima had placed a strategic emphasis on building its ProMade custom implant business, a market segment that can benefit greatly from the use of additive manufacturing and that is fairly underserved in the orthopedic industry.”

“Because of HSS’ unique competency in treating complex joint reconstruction conditions and experience in design and use of custom, patient-specific implant solutions, both organizations saw another opportunity to partner and leverage each other’s complementary talents.”

The new on-site facility at HSS is the product of this collaboration, and it will be used for the design and production of patient-specific, 3D printed medical devices.

Over a decade of 3D printing in healthcare

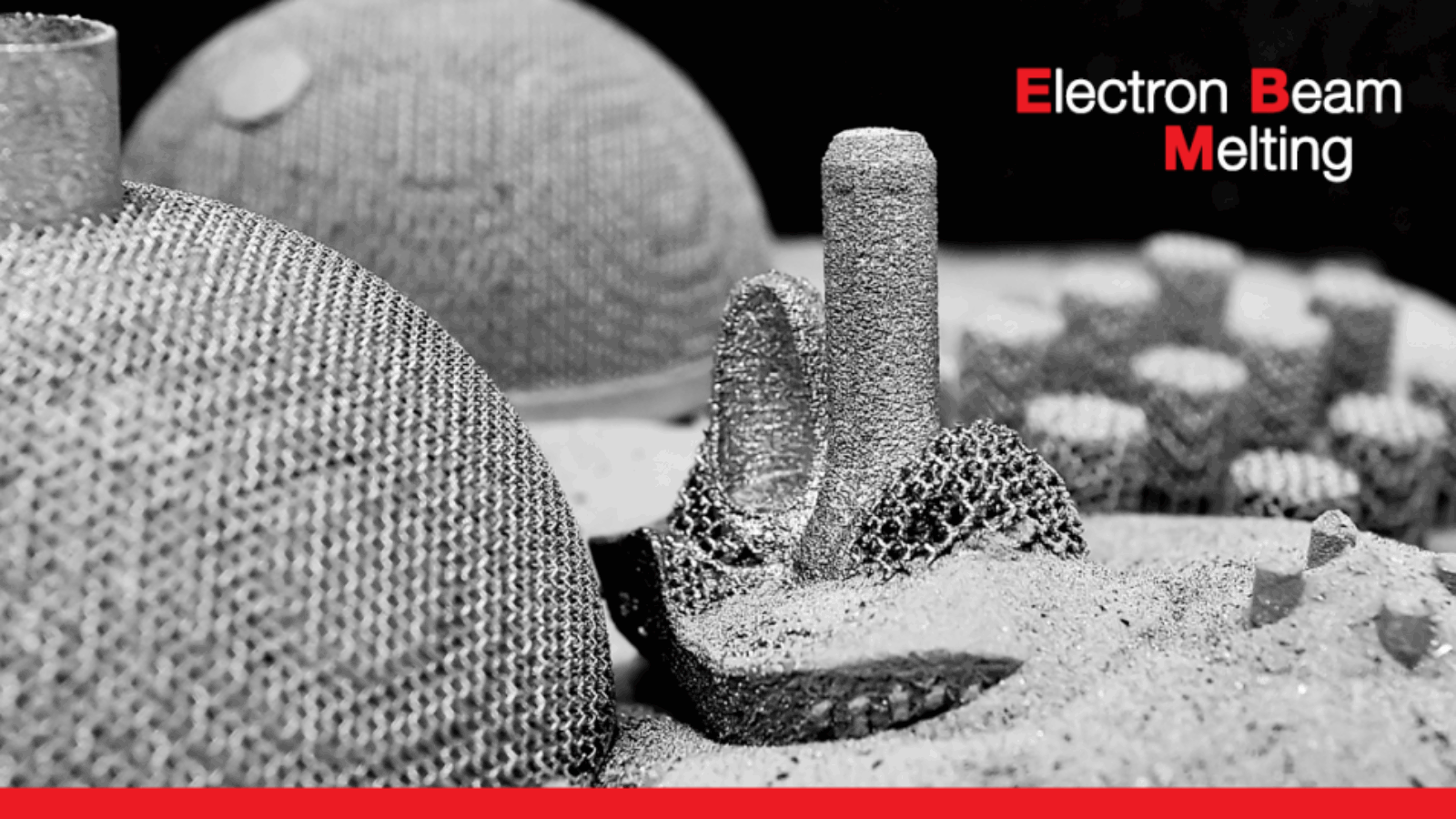

3D printing was commercially introduced at LimaCorporate in 2007. Using a patented Trabecular Titanium technology, the company produces implants that mimic the natural structure of bone. GE Additive company Arcam is responsible for 3D printing Lima’s devices using its electron beam melting (EBM) technology. The trabecular titanium hip cup, in particular, has now proven to be effective after over 10 years of implantation within a patient.

In addition to improved cell-ingrowth (when compared to traditionally manufactured implants) by 3D printing medical devices, Lima gains the ability to custom fit each one to the patient. By integrating 3D printing capabilities with the HSS in New York, the partners are hopeful of an even more symbiotic relationship between clinicians and technicians, resulting in an improved patient experience.

Manufacturing on Demand

“Because of the closer proximity of Lima engineers in the U.S. we anticipate increased interaction between clinicians and designers and a faster design process for each custom case,” adds Achan. “By fabricating in NYC, it is expected that these devices will avoid time-consuming international transfers and shipping.”

“Finally, leveraging Lima’s competency in additive manufacturing will help minimize the need for more time-consuming conventional fabrication methods, allowing for quicker turn-around of devices.”

3D printing in hospitals

On-site facilities are one of the most promising, and potentially life-changing, developments for the future of 3D printing in healthcare. Other facilities that have already taken the initiative to bring 3D printing on-site include Minnesota’s Mayo Clinic, with the Anatomic Modeling Lab, the Cardiac 3D Print Lab at Phoenix Children’s Hospital, Arizona, and the University Hospital of Basel, in Switzerland, with its 3D Print Lab. From the UK, award winning company 3D LifePrints has made introducing 3D printing facilities to hospitals its mission.

Concluding comment on the new LimaCorporate facility, Achan says, “It is expected that this enhanced partnership and collaboration will lead to new innovations in the treatment of complex joint reconstruction.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Beau Jackson

Leave A Comment