LafargeHolcim and XtreeE have strengthened their strategic partnership, which dates back to 2016, to develop innovative solutions for sustainable construction. The story, reported by several credible French media sources, indicates that as a 20% shareholder in XtreeE, LafargeHolcim France becomes a director and thus joins the Co-founders of the company, Vinci Construction Invest and the investment fund Shibumi International.

This operation aims to strengthen the association of technical and R&D know-how between the two companies to accelerate the development and marketing of industrial 4.0 solutions for the sustainable construction of buildings and infrastructure.

Proficient, commercial 3D printing of construction materials has been taking off in many areas of the world, from the Middle East and Africa to Germany and the US, and it is indeed one of the responses to the necessary ecological transition in this economic sector.

Manufacturing on Demand

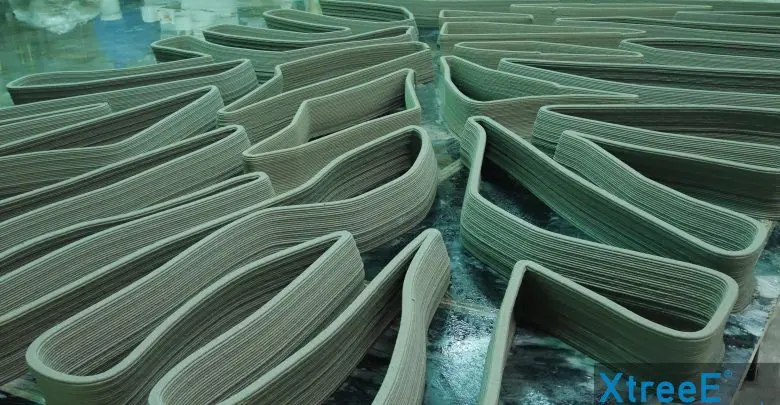

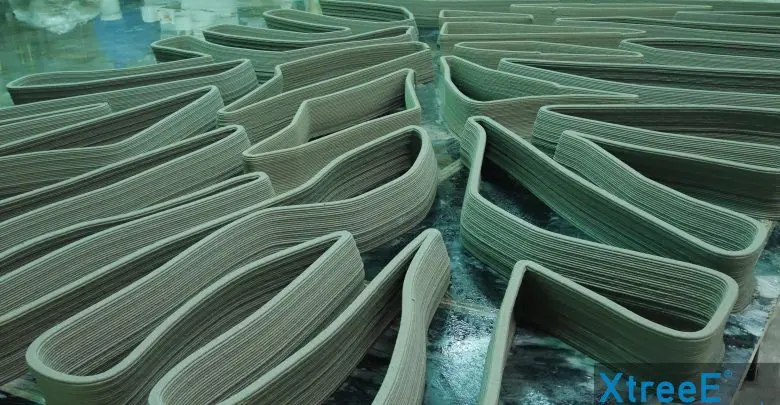

It allows the quantities of materials used to be limited thanks to digital design and manufacturing: up to 60% less concrete on certain projects; implementing new structural printable materials with a reduced CO2 footprint. AM implementation in constructions is a necessary step to realize complex structural elements in printed concrete at controlled costs and deadlines thanks to tailor-made solutions that reduce the nuisance of construction sites and improve the quality of construction, through off-site manufacturing.

In 2016, LafargeHolcim first seized opportunities in the 3D printing market by entered into a partnership with the French start-up XtreeE, which developed some of the first large-scale cement 3D printing systems. This alliance made it possible, for the first time in Europe, to market a concrete structural element created using a 3D printer.

Bringing the digital revolution to the construction industry, 3D printing allows complex geometric structures to be created at a reasonable cost and with shorter production times compared to traditional techniques. LafargeHolcim then identified three potential markets: high value-added architecture, the individual construction of affordable homes, and the robotic construction of prefabricated building elements.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment