German startup iFactory3D is presenting the iFactory One, 3D belt printer with a brand-new error protection system called PrinterGUARD.

PrinterGUARD allows the iFactory One to identify the five most common 3D printing errors: spaghetti, detached objects, warping, stringing, and air printing. According to iFactory3D management, in the near future, the company’s self-learning artificial intelligence (AI) algorithms are expected to recognize up to 20 types of errors, and the PrinterGUARD protection system will be able to eliminate all of them.

“A private poll of 1,000 3D printer users found that these printing errors occur in approximately 20% of all cases. Before the iFactory One entered the market, error diagnostics and the human aspect led to great losses for manufacturers. But the defect ratio can be minimized by means of the custom 3D solution,” said Artur Steffen, CEO of iFactory3D.

The iFactory One has a range of benefits. Its pyramid shape allows it to print at an angle even if the surface is imperfect. Thanks to a specially designed integrated belt mechanism and a 45-degree hot end, the iFactory One can replace a big 3D printing farm and print as many prototypes of infinite length as needed (rails, bridges, architectural models, etc.).

Manufacturing on Demand

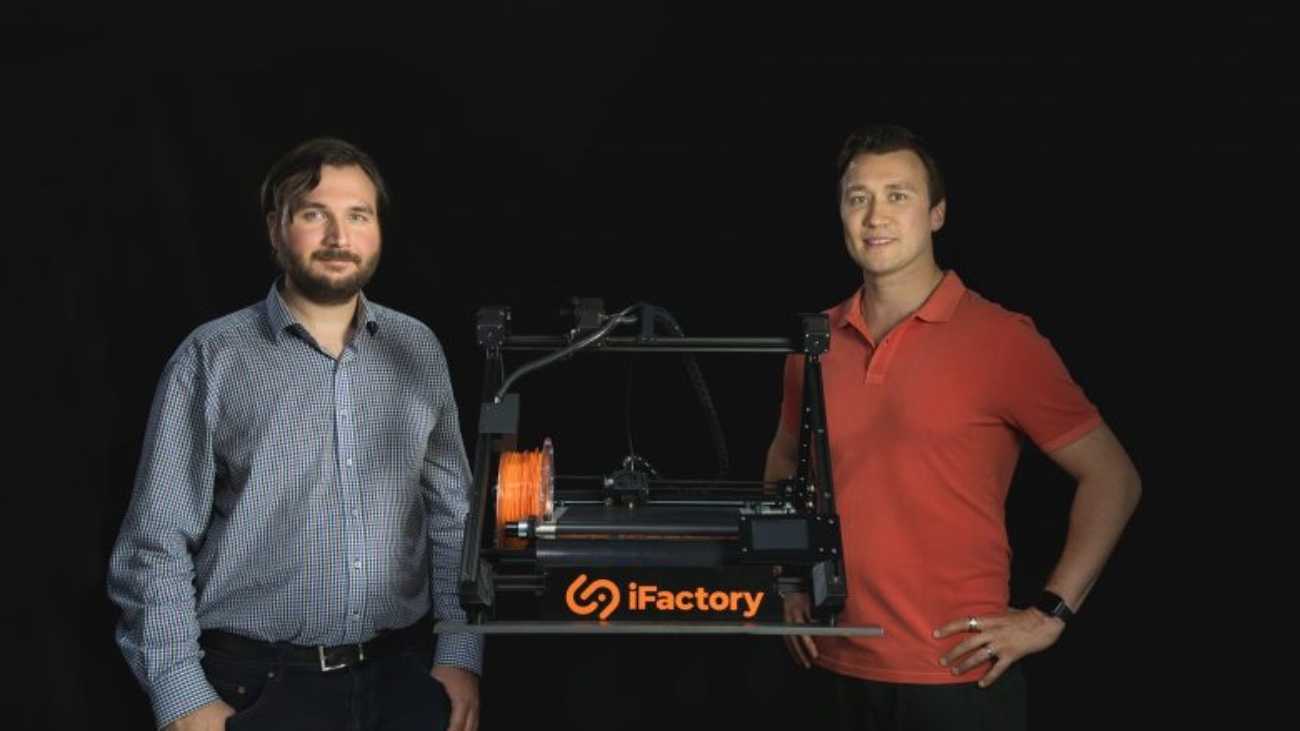

The iFactory3D company, based in Dusseldorf, Germany, is headed by German serial entrepreneur Artur Steffen who founded the company in July 2020 together with inventor and chemical engineer Martin Huber.

The idea of the iFactory One came to Martin when he had to make printed parts (that would normally cost ~$20,000) for a device. In order to save money and time, he decided to print these parts on his own. At first, Martin purchased one printer, then one more, then another…

Finally, he had a real 3D printing farm! Of course, supervising this operation required a lot of time. Looking at the resources he was wasting, Martin decided to design a better printer. What he came up with is the iFactory One, a multipurpose device that allows creative makers, hobbyists, and designers to print items of unlimited size without needing to control the printing process.

In September 2020, iFactory3D received a financial contribution from STARTPLATZ, the largest business accelerator and coworking space for the startup community in Western Germany.

You might also like:

A closeup of Sinterit’s complete SLS 3D printing ecosystem: As part of Sinterit’s overarching mission to prioritize customer experience (without compromising quality, of course), the company has a suite of products that cover 3D printing, materials handling, part removal and cleaning, as well as a comprehensive workflow software solution. Though it’s rare to get a full picture of a company’s product portfolio, it is sometimes necessary to understand the full value of the offering, like how a recipe is more than just the sum of its parts. Keep reading to understand how each of Sinterit’s products fits into the company’s bigger picture.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: VoxelMatters

Leave A Comment