With the new GMP300 metal 3D printer, GROB, a German company specializing in automated production systems, looks to offer its customers a production system for the manufacturing of near-net-shape components via AM range for the first time. The new LMP (Liquid Metal Printing) system, which was first unveiled at a GROB in-house exhibition, announcing the entry of GROB-WERKE into the Additive Manufacturing sector, has now also been presented at the ongoing Additive Manufacturing Forum in Berlin.

As powder bed fusion (PBF) using lasers is currently the most common process in the Metalworking sector, GROB-WERKE looks to address critical aspects, such as the high raw materials cost in conjunction with the effort involved in handling the powder, the low build-up rates of many systems and the concurrent long process times, as well as the high degree of work needed for the required post-processing steps. As with every process in Additive Manufacturing, the functional surfaces require additional processing post-PBF, canceling out the advantage of good component resolution in the actual process. The many disadvantages work against actual economically viable use.

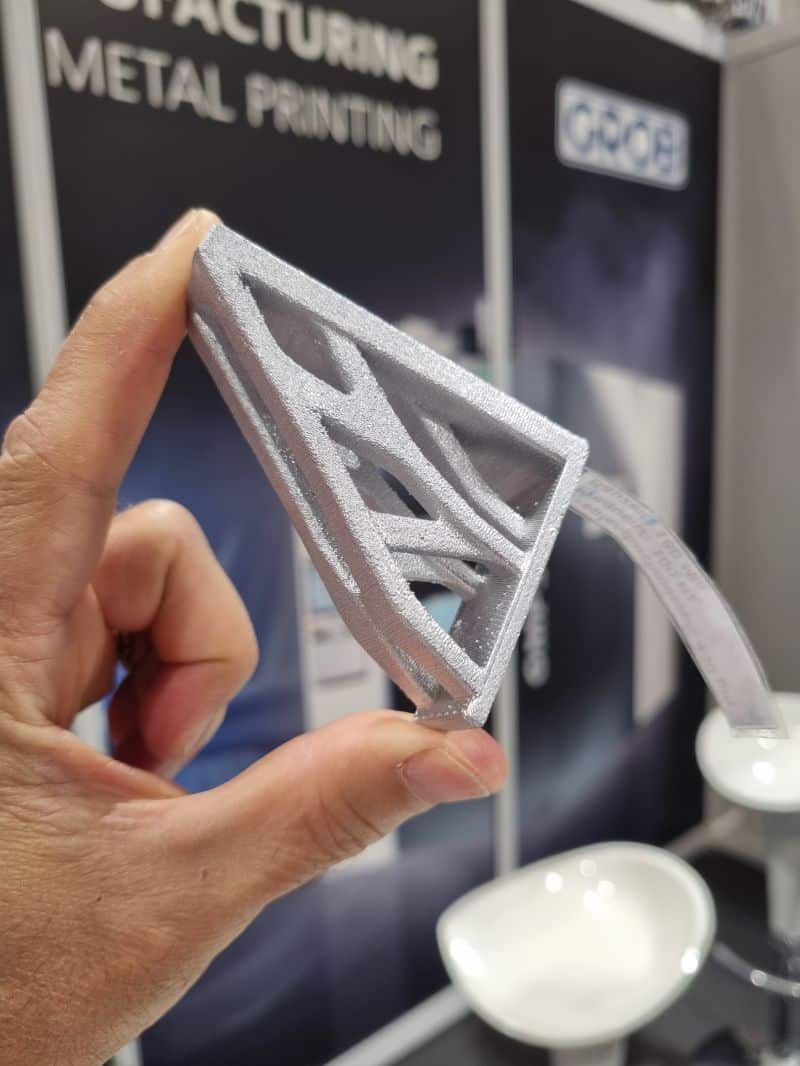

New GROB GMP300 manufacturing

In light of this and to suit the market requirements for customized and near-net-shape products, Liquid Metal Printing (LMP) was developed at GROB as a future-oriented, economically sound and at the same time flexible Additive Manufacturing process that eliminates the disadvantages of traditional Additive Manufacturing in the Metalworking sector.

With the GMP300, GROB offers its customers reliable, efficient and cost-conscious system technology with maximum production flexibility for individual and small-series production. GMP stands for GROB Metal Printing, and 300 for the size of the work area, 300 x 300 x 300 mm³, in the machine. The GMP300 is equipped with 3-axis kinematics and maximum axis speed of 30 m/min. The inert atmosphere protects the component from oxidation, guaranteeing consistently good material quality.

Manufacturing on Demand

Advantages of the GROB LMP process

In contrast to the known powder bed fusion process, the raw material for the GROB-developed LMP process is wire. This reduces not only the material costs. Additionally, the use of wire poses no health or explosion hazard, making personal protective equipment worn simpler, and omitting additional work steps such as component de-powdering and the sifting and processing of the powder. Also, the LMP process is a micro-casting process and not a welding process, having little to no thermal warping. This allows for the processing of non-weldable alloys.

The LMP process generates a homogenous microstructure with yield strengths equal to or also sometimes greater than the raw material values. In addition to this, the process provides impressively high flexibility and productivity. Flexibility is achieved by the ability to change materials quickly with no excessive cleaning effort, by the highly variable drop diameter and by the ability to change both printhead and nozzle during the build-up process. The high productivity of the LMP process is won primarily via the achievable high build-up rates, the reduced post-processing work, and the fact that the component costs scale to only slightly above the filling level of the construction base.

Future-oriented LMP technology

LMP technology is not yet widespread on the market. GROB views it as an important addition to the existing metalworking Additive Manufacturing processes nevertheless. Its process prevails with a higher build-up rate than comparable PBF systems, and with better component resolution compared to current DED (Direct Energy Deposition) processes.

During the development of the GMP300, GROB had already moved to ensure robust and industry-ready implementation. “With no powder handling, integration of the system into an existing production line can be carried out without increased safety precautions,” claimed Johannes Glasschröder, Doctor of Engineering and Additive Manufacturing team leader, citing another advantage. “In addition, we envision a great synergy effect for the required post-processing of functional surfaces with our existing portfolio in the machining range.”

You might also like:

Titomic sells first four D523 cold spray systems into the transport industry: The systems have been sold to four businesses in the engine remanufacturing and rail transport sectors, all of which are looking to add in-house capability for ongoing component services and repairs to maximize equipment uptime while minimizing maintenance costs.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: VoxelMatters

Leave A Comment