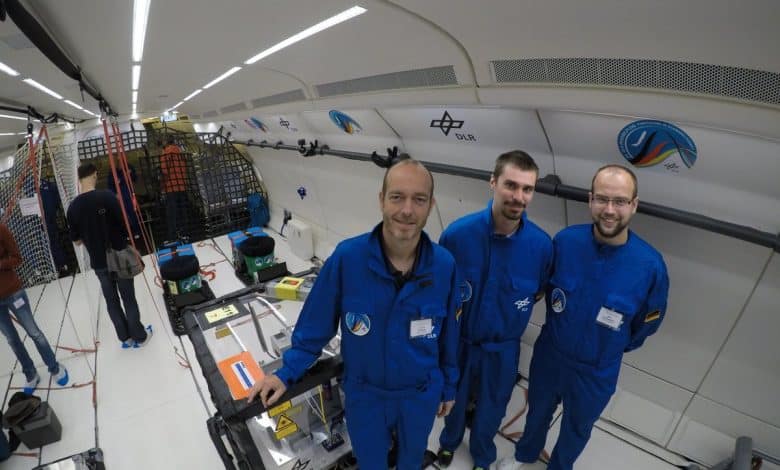

The German Aerospace Center DLR is ready for parabolic flight. The aircraft will test a new metal powder bed fusion additive manufacturing system under zero gravity conditions that have been developed since 2017. The machine is based on tried and tested principles and is designed to study the payload of the rocket. It will be launched on the MAPHEUS rocket for the first time in 2020.

The subject of the DLR research project is the SLS/SLM process (selective laser sintering or selective laser melting), where the required components are formed layer by layer from the metal powder by a focused laser beam. Even if adjusting different machine parameters sometimes requires a series of complex measurements, the range of materials that can be used with this process is very wide.

In the process of reducing gravity to complete weightlessness, one of the biggest challenges facing this process is the handling of metal powder. This includes the targeted application of dense powder layers of uniform thickness, as these parameters determine the quality and material properties of the final part. This layer must also remain stable on the printing bed until laser processing is completed and the next layer is applied. To achieve this goal, an airflow is applied and effective powder is effectively “sucked” into the print bed. This method of stabilizing the powder over the entire pressure range has been tested in previous parabolic flights and has shown high reliability.

This newly developed additive manufacturing device for the upcoming experiment is fully automatic, has an independent energy supply, is rugged enough to withstand the loads that occur during rocket launches, and is lightweight. The telemetry connection can be used to monitor the manufacturing process from the ground. During the parabolic flight, the rocket payload and ground station will work side by side. In addition to testing the hardware for the first time in a weightless state, the experiment will also study the optimization of system parameters for different, more demanding materials (for example, solid metal glass).

Additive manufacturing (also known as 3D printing) provides a wide range of options for manufacturing components from liquid, powder, or filamentary materials. All types of materials can be 3D printed, including metals, plastics and ceramics, and composite materials. More and more raw materials have reached the maturity of the technology market.

The advantages of this group of manufacturing processes depend to a large extent on the processes and applications used. All in all, additive manufacturing can be used to manufacture a large number of parts or tools from the same raw materials very flexibly and quickly. However, one of the most important advantages of using AM in space is the ability to produce parts where they are needed. Therefore, the application of space travel—on or outside Earth, for example, at the base of the moon or Mars and during the flight there—will be of great interest in the future of human space travel.

Such manufacturing processes, even if they have undergone sufficient testing and are ready to be put on the market on the earth, are by no means easy to adapt to the reduced gravity. On the one hand, there are fundamentally different requirements for the hardware of the corresponding production machines, on the other hand, more complex materials are often used in space travel.