3D printer manufacturer Formlabs has made a whole slew of new hardware, software, and materials announcements concerning its dental 3D printing business.

Firstly, the firm’s Fuse 1 SLS system has been validated for the 3D printing of orthodontic models, and is currently being showcased at the International Dental Show (IDS) in Cologne. The company is also set to reformulate its popular Model Resin to double printing speeds on its SLA systems. Finally, Formlabs’ Form 3B, Form 3BL, and Fuse 1 printers have all been validated for integration with software developer 3Shape’s Clear Aligner Enterprise platform.

“Dental manufacturing demands a high degree of customization, and 3D printing is the key solution to enabling that customization at scale without sacrificing cost, speed, or quality,” said Dávid Lakatos, Chief Product Officer at Formlabs. “With more than ten dental-specific resins powering our SLA line of printers, we are disrupting the dental market with high-speed resins for dental practitioners and labs to create high-quality, patient-specific dental products.”

Fuse 1 for dental 3D printing

The Fuse 1 is Formlabs’ debut SLS 3D printer. Marketed as the world’s first benchtop industrial SLS system, it offers a build volume of 165 x 165 x 300mm and a 10W fiber laser, all at a significantly lower cost than conventional sintering competitors.

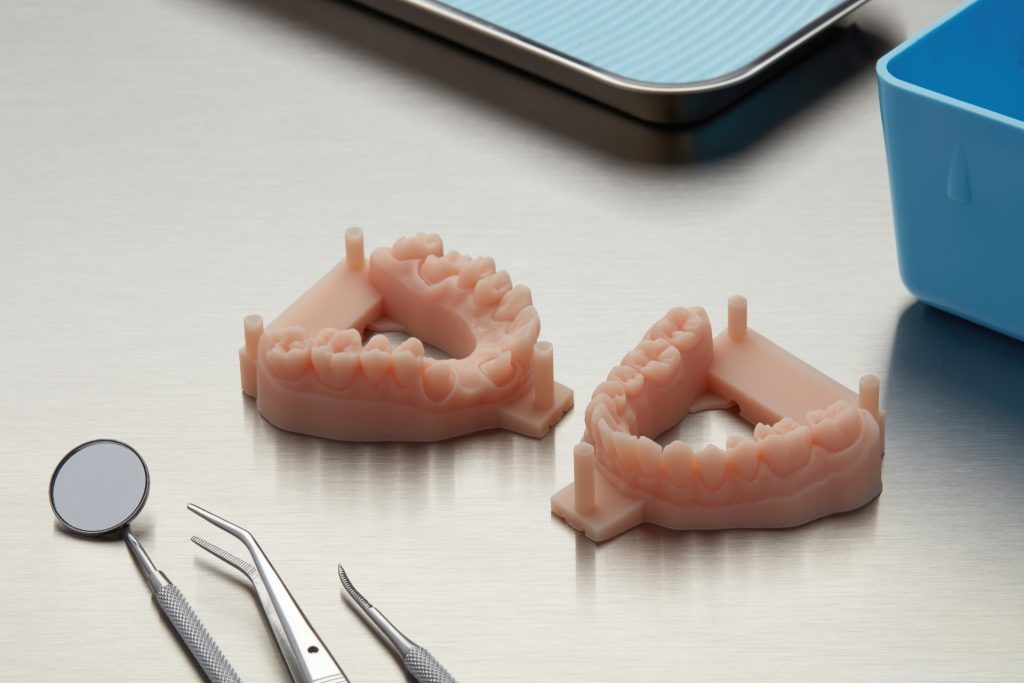

Having now been validated for orthodontic 3D printing applications, the Fuse 1 is expected to reduce labor costs and lead times for both dental labs and dedicated clear aligner manufacturers. The system is able to produce more than 150 dental models in a single print and reportedly cuts the cost per part by 50% when compared to traditional production methods.

Lakatos adds, “Now with the Fuse 1’s validation for dental manufacturing, we are expanding our dental offerings to our SLS line of printers and enabling even greater speed, versatility, and affordability for our dental users.”

Formlabs’ Model Resin reformulation

Manufacturing on Demand

The company’s popular Model Resin is designed specifically for crown and bridge models, orthodontic models, implant models, clear aligner models, and diagnostic models. With the upcoming reformulation, Formlabs is aiming to vastly increase the production output dental labs can achieve in a day with their Form 3B and Form 3BL printers.

Specifically, the new formulation is set to increase print speeds by up to 100% while reducing the overall work time (including post-processing) by an impressive 60%.

Integration with 3Shape’s Clear Aligner Enterprise platform

3Shape’s Clear Aligner Enterprise software serves as a one-stop-shop for digital treatment planning and 3D printing workflow management. The software firm has now validated the interface between its platform and Formlabs’ SLA and SLS systems, meaning the Form 3B, Form 3BL, and Fuse 1 systems are confirmed for clear aligner model production. According to the partners, the Fuse 1 is the first SLS 3D printer to be validated for the application by 3Shape.

Sam Wainwright, Formlabs’ Dental Product Manager, said, “Formlabs Dental is laser focused on making flexible and patient-specific treatment protocols accessible to every dental professional through 3D printing. To achieve this we are constantly looking for partners – 3Shape recognizes the benefits of our printers; they are affordable, easy-to-use, and ultimately fulfill the industry’s need to digitize workflows to optimize the patient experience.”

Also targeting the dental 3D printing sector, IBM Watson Health, the healthcare arm of technology consultancy IBM, recently launched the latest version of IBM iConnect Access, the company’s diagnostic and medical image exchange platform. The updated platform comes complete with an early version of a future 3D printing feature, whereby users will be able to 3D print lifelike anatomical models using patient medical imaging data directly from the platform itself.

Elsewhere, addressing the need for dental materials, Desktop Metal’s healthcare subsidiary Desktop Health recently launched a chrome cobalt binder jetting material specifically for dental applications. Compatible with the company’s Shop System, the AM powder is designed for the printing of custom bridges, crowns, partial dentures, and surgical guides.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment