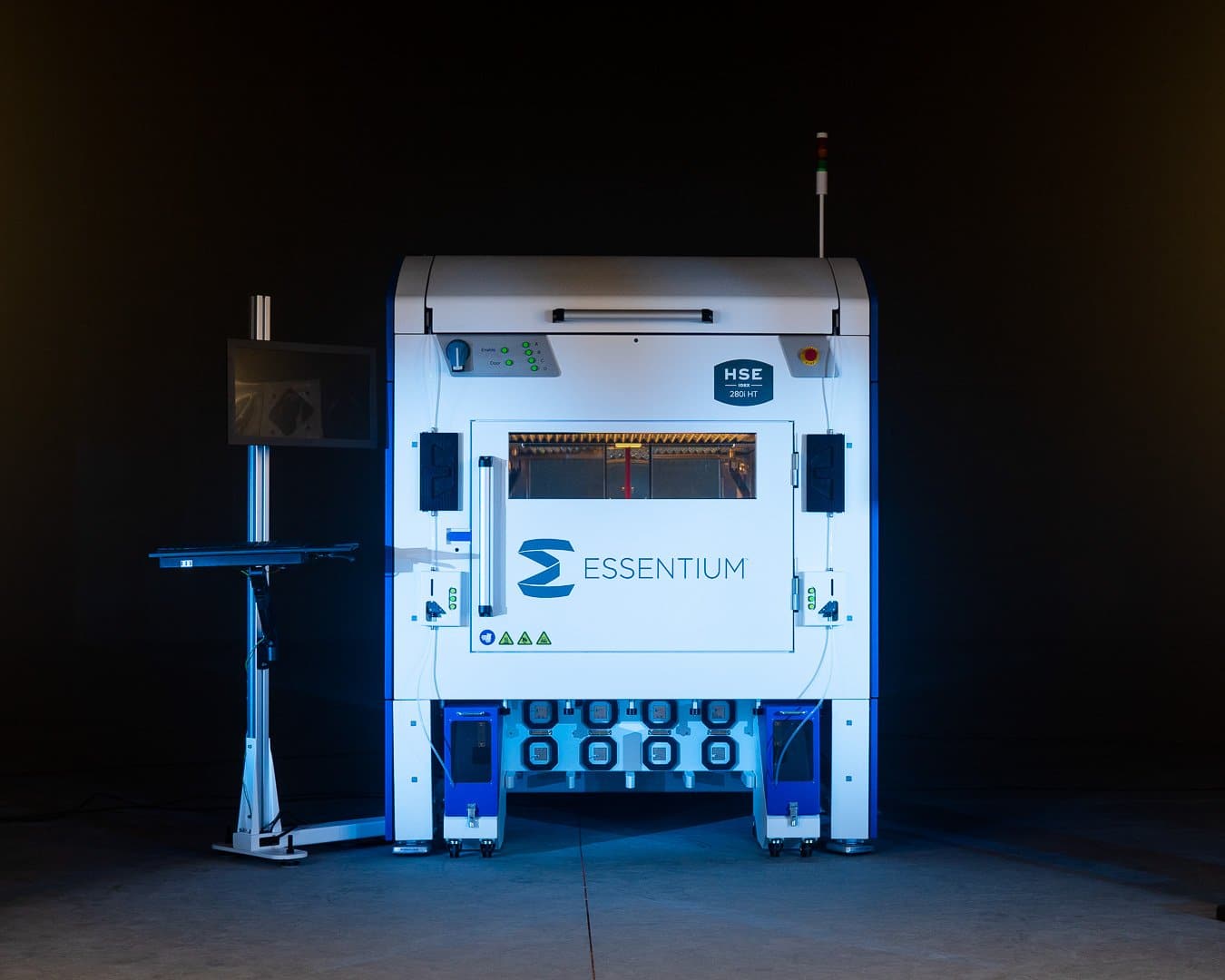

Essentium, Inc., a worldwide leader in industrial additive manufacturing, has partnered with Braskem, one of the largest polyolefins producers in the Americas and a market leader and pioneer producer of biopolymers on an industrial scale, to offer manufacturers a fully integrated AM machine and materials solution. Combining Essentium’s High-Speed Extrusion (HSETM) 280i HT 3D printer with Braskem’s polyolefin materials is intended to unlock affordable, sustainable, and rapid volume production of 3D printed thermoplastic components.

Manufacturing on Demand

Together Braskem and Essentium will be able to further unlock the possibilities of these materials by leveraging the advanced functionality of the Essentium HSE 280i, the first truly independent dual extrusion system (IDEX) providing an open platform with precision control over printing conditions and high printing speeds – enabling the rapid production of parts with repeatable results.

“Our partnership with Essentium is a huge win for manufacturers worldwide. The fact that Essentium offers a high-speed, open platform means that manufacturers can now benefit from sustainable and responsible material options that are also extremely affordable. Together with Essentium, we are democratizing 3D printing and providing a competitive option to more industries,” said Jason Vagnozzi, Global Commercial Director of Additive Manufacturing at Braksem.

“With Braskem, we have a true partner who shares our commitment to developing sustainable solutions to accelerate industrial-scale additive manufacturing. Polyolefins are ideal for AM due to their recyclability, impact strength, chemical resistance, and durability. This makes them a great choice for automotive, aerospace, biomedical, and packaging applications. Our partnership with Braskem will empower manufacturers with integrated solutions as AM moves towards prime time in their industries,” said Blake Teipel, CEO of Essentium.

You might also like:

NGK to co-develop ceramic materials for Sakuu’s printed batteries: “Formalizing this long-term partnership agreement with NGK for ceramic needs across our printed battery line is an important step in Sakuu’s commercialization plans,” said Arwed Niestroj, SVP of Customer Enablement at Sakuu. “NGK is a global industry leader, and its material quality and technical expertise will allow Sakuu to rapidly advance towards bringing to market our next-generation battery line.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment