EOS has been a development partner of the Oqton manufacturing operating system (MOS) since 2020, working on streamlining additive production. Moreover, the company conducted an extensive, year-long investigation into available systems to support its own internal production capabilities. EOS came to the conclusion that Oqton is the right platform to serve its purposes for connecting, tracking, optimizing and automating its manufacturing operations. EOS and Oqton are offering combined solutions for additive manufacturing customers because of the deep integration, which is unique in the world of additive manufacturing.

After raising $40 million from investors such as leading metal AM powder supplier Sandvik, Oqton is now working even more closely with EOS, a recognized pioneer, leading the way in developing innovative and integrated solutions for additive manufacturing. The AM hardware manufacturer’s machine software had also already been integrated into the Oqton platform.

The benefits that the Oqton platform is now delivering for EOS are widespread both internally across multiple EOS locations and for optimizing the production capabilities of its clients. EOS was aiming to increase efficiency and productivity across multiple geographical locations to use the internal available production capacity in the best possible way.

Manufacturing on Demand

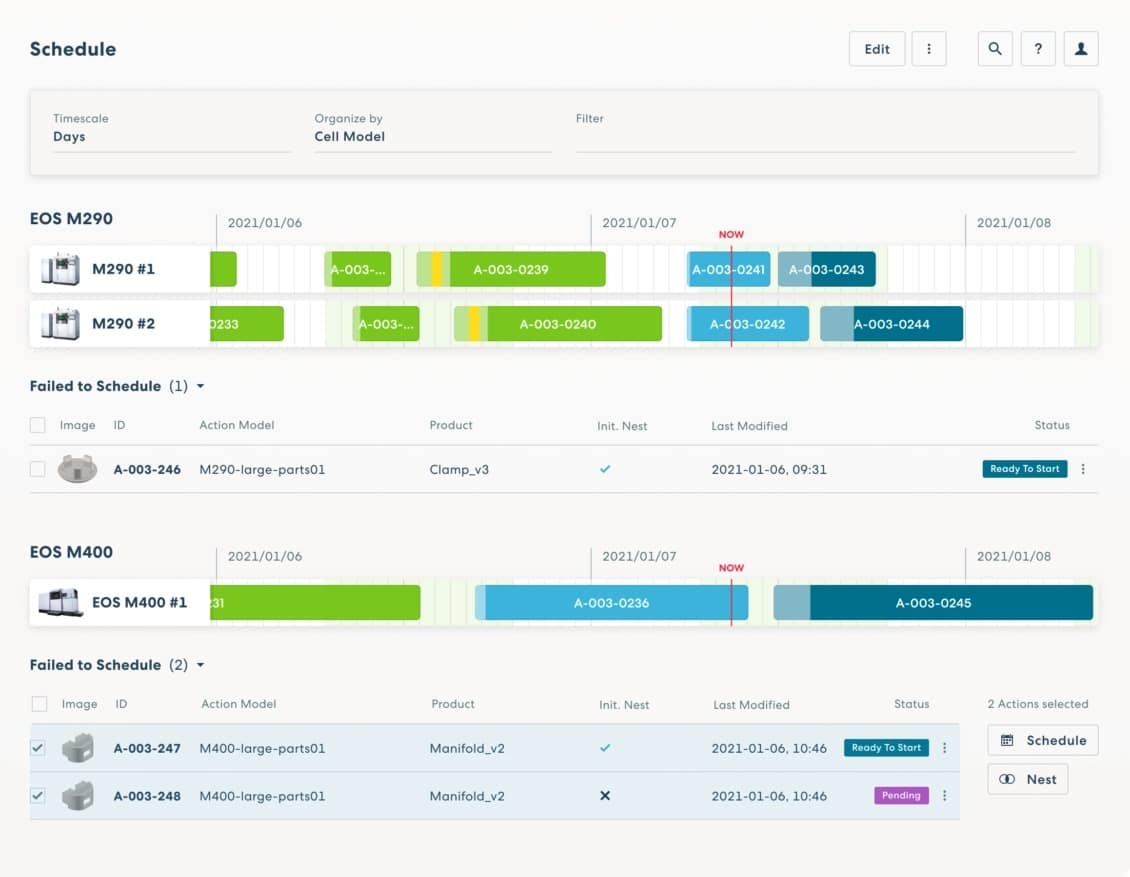

The implementation of the Oqton manufacturing platform has taken place across 8 of EOS’ global production facilities, with more than 100 additive manufacturing systems, as well as ancillary equipment including post-processing, now connected and coordinated by a single operating platform. The MES and IIoT capabilities of Oqton provide EOS with the security and power to manage all of its resources and machines and has improved planning to significantly drive productivity upwards.

Trevor Kirsten, Head of Digital Manufacture at EOS, has been impressed with the Oqton platform . He commented: “The decision to implement the Oqton platform at EOS was based on the strengths that we identified, specifically that Oqton can integrate all of our factory equipment (the industrial 3D printers, periphery equipment, and post-processing). This greatly improves our planning and efficiency both with the machines and personnel. And because Oqton provides good machine connectivity we can monitor machine states in real time and send print files from the MES directly to the 3D printer.”

He continued: “In addition, the low code approach of Oqton allows us to easily tailor workflows and dashboards, the platform is interoperable with other software systems, which is also very beneficial for us. Oqton has proven itself to be very customer-focused and agile by functionality and creates new features very quickly in response to EOS inputs. At EOS, we are convinced that the Oqton platform will help us and our customers to take AM based production to new levels of efficiency and effectiveness.”

Oqton’s CEO, Ben Schrauwen further commented: “At Oqton we are delighted to be working with one of the pioneers of additive manufacturing and to bring added value to this impressive company. Additive manufacturing has proven itself to be a truly disruptive technology and the benefits are well documented. However, we all know that there are still issues challenges to resolve when it comes to AM facilitating production at scale. Oqton was founded to resolve these core issues and we are now able to demonstrate that effectively and consistently, as the results at EOS show.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: 3D Printing Media Network

Leave A Comment