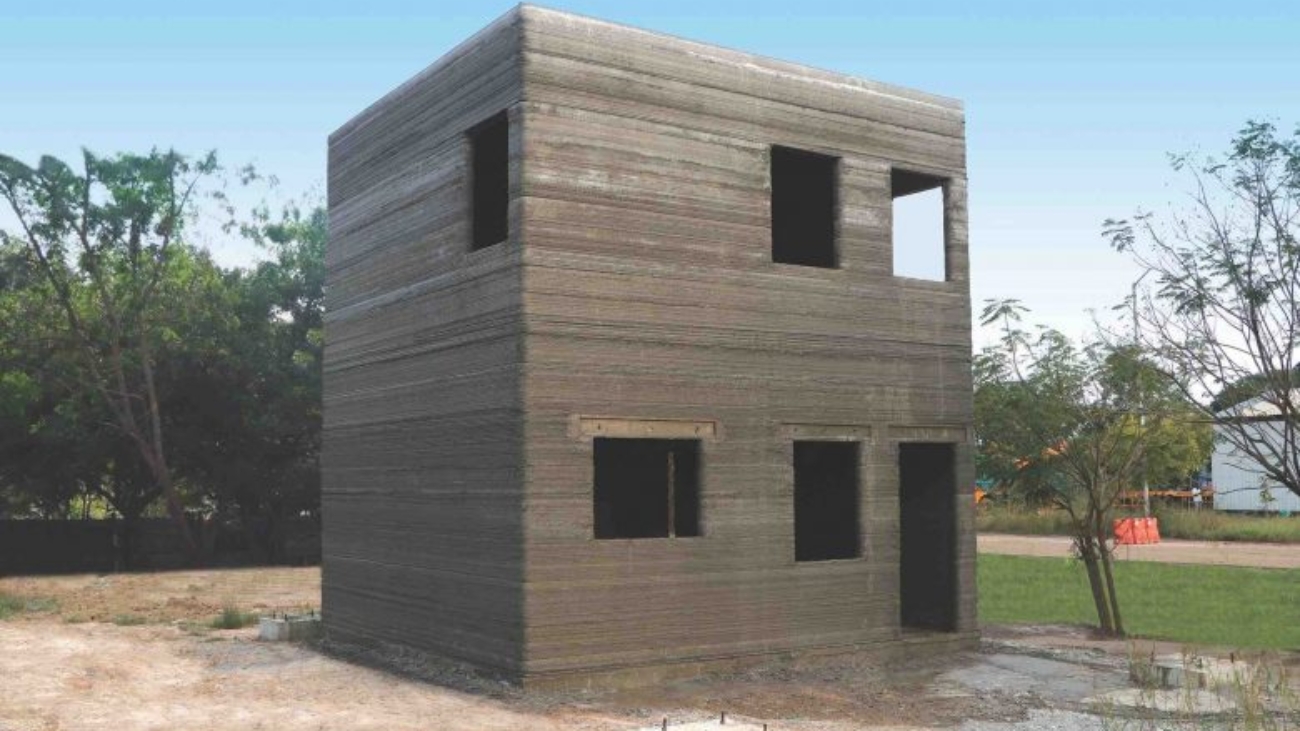

COBOD, a company that specializes in 3D printing buildings, printed a concrete two-story building in India made by L&T Construction, a first for the AM industry.

L&T Construction is the construction arm of the twenty-one-billion-dollar technology, engineering & construction conglomerate Larsen & Toubro. It is India’s largest construction company and ranked among the world’s top thirty contractors. L&T Construction has recently 3D printed India’s first two-story building (G+1) of sixty-five square meters using a concrete mix developed by their in-house team. This mix is based on locally available raw materials and methods for integrating reinforcement with the 3D printed concrete in an open-to-sky environment.

Manufacturing on Demand

COBOD’s 3D printing system successfully completed the building using this mix. The new building is located close to Chennai and is the second building L&T has made with COBOD’s printer, the first being a one-floor twenty-two-square-meter building with a bedroom, hall and kitchen.

Henrik Lund-Nielsen, the founder and general manager of COBOD, said that:

L&T Construction’s project marks a huge step forward for our industry, on a global scale. Not only is the project showing that more and more conventional construction companies are adopting 3D printing, but the 3D printing of a real concrete made by L&T themselves is significant, as this helps to drive down the cost even further. It is really impressive how L&T developed the 3D printable concrete and applied integral horizontal and vertical reinforcement in the building.

You might also like:

WASP completes its TECLA 3D printed house: TECLA (which takes its name from Technology and Clay) was made in Massa Lombarda (Ravenna, Italy) with the Crane WASP, WASP’s brand new 3D printer in the construction sector. The construction was an AM challenge because it maximized the performance of one of the oldest construction materials that is also used in the green economy: raw earth.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment