Finland-based bioprinting firm Brinter has launched what it claims is the world’s first multi-material, multi-fluidic bioprinting printhead.

Designed for use with the firm’s own 3D bioprinters, the is currently undergoing pilot testing with a limited number of customers. Aimed at research institutions and pharmaceutical companies, the device is defined by its extensive material capabilities and hopes to enable higher-precision tissue engineering and regenerative medicine applications, including tissue damage repair, biological function replacements, and localized disease treatments.

Tomi Kalpio, CEO of Brinter, said, “The key to achieving this world-first was the accumulated experiences of our team members utilizing our proprietary hardware architecture, software, and fluidic automation system knowledge to make complex fluidic circuits, which have near zero dead volumes to save resources and to avoid cross contamination with other materials.”

3D bioprinting with Brinter

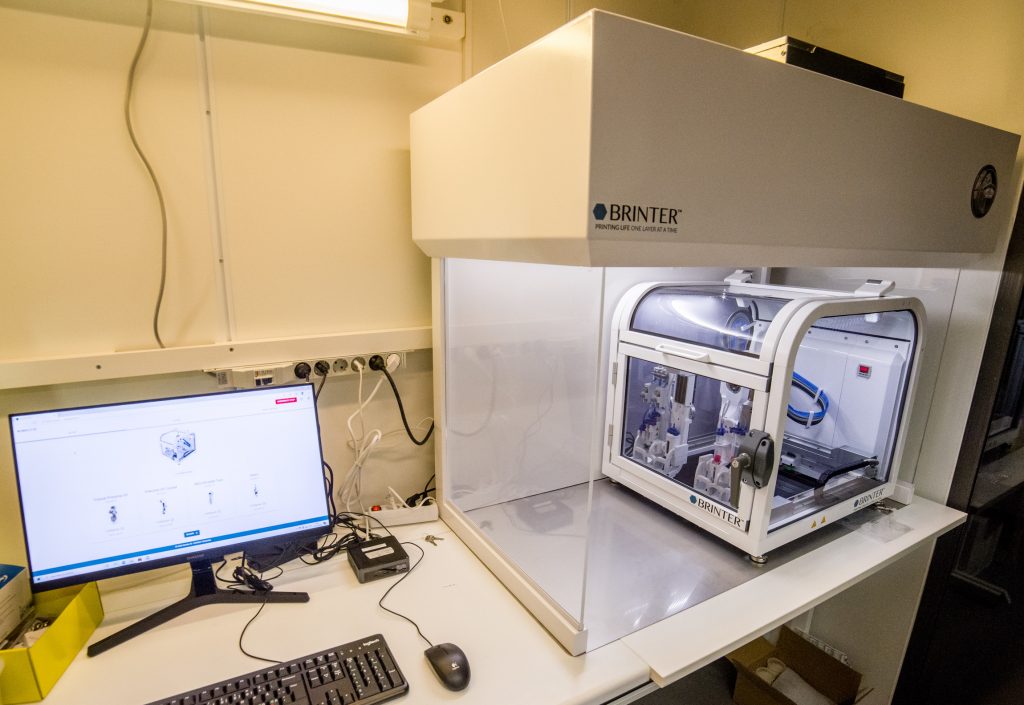

Established in 2020 as a spin-out from 3D printing service bureau 3DTech Ltd, Brinter specializes in 3D bioprinters, inks, and related hardware for customers in the pharmaceutical, biotech, research, and cosmetics sectors. The company currently has clients in over ten countries such as the USA, the UK, and Germany, including Nanoform, Johannes Gutenberg University of Mainz, University of Oulu, and the University of Helsinki.

Last year, Brinter made headlines when it secured €1.2 million in seed funding to expand its day-to-day operations and bring its bioprinting offering to the US and European medical markets.

The company’s debut bioprinter is its flagship Brinter One, a multi-material deposition-based machine that works with both stiff and soft cell-laden hydrogels. More recently in November, Brinter also launched an entry-level model called the Brinter Core. Designed to make bioprinting as accessible as possible, the Core is around half the size and cost of its predecessor.

March 2022 was also an active month for Brinter, when it partnered with extrusion technology developer Puredyne to launch its new Visco Bio printhead. Shortly after, the firm teamed up with Tampere University’s Kellomäki Lab Biomaterials and Tissue Engineering Group to develop new bioinks for use with the technology.

Manufacturing on Demand

The first multi-material, multifluidic printhead

The most noteworthy feature of the new multi-material printhead is its ample tunability. It’s possible to modify the hardware with different temperature control and imaging options to make it compatible with a wide variety of material types. According to Brinter, the printhead is capable of printing up to 4,096 different material combinations in a single build.

Without this tunability, a new printhead might be required for every type of printing material, which is greatly inconvenient when processing granulates, pastes, and liquids. The list of material capabilities also includes hydrogels with living cells, biopastes, metal-infused binders, and even polymers.

Kalpio states that the printhead serves to bridge the gap between the micro/nano/pico/femto fluidic environments and the bioprinting environment, granting users the utmost level of deposition precision.

As such, the number of potential Brinter use cases is significantly expanded. The company claims customers will be able to generate gradients across their bioprinted structures, program the cells in the droplets to make personalized drugs, and even functionalize printed materials to perhaps one day target cancer cells or heal and regenerate tissues.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Kubi Sertoglu

Leave A Comment