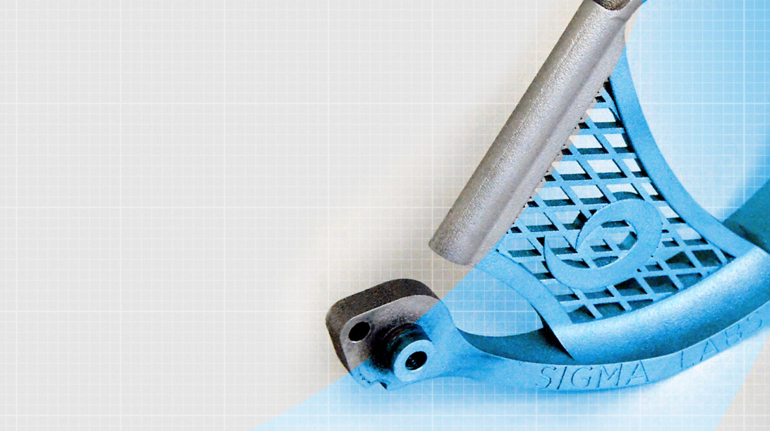

BMW i Ventures Confirms Investment in Affordable Metal 3D Printing 3D Printing Processes

BMW i Ventures has announced a strategic investment in Desktop Metal, an emerging startup with the mission to bring metal 3D printing within reach of all design and manufacturing teams. Desktop Metal is committed to accelerating the adoption of metal 3D printing in manufacturing through the creation of innovative technology that produces complex parts. They are doing this with a world-class team of experts in the fields of materials science, engineering and software, consisting of 75 engineers.