SyFy Pushes 3D Printing with New 12 Monkeys 3D Models on Thingiverse AM Industry

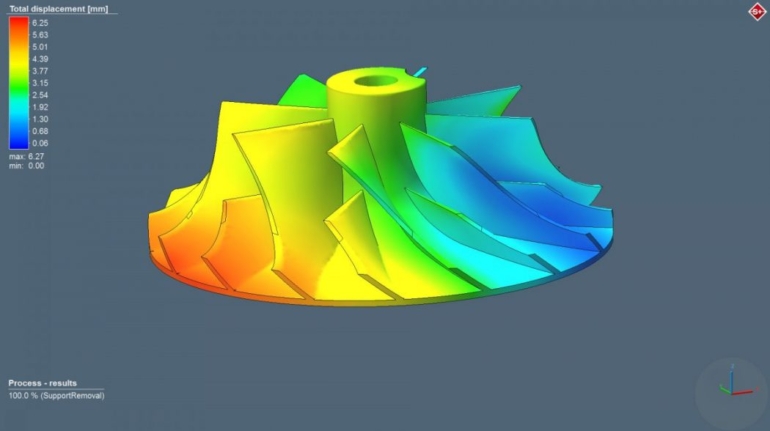

Since it was launched at the beginning of 2016, SyFy Channel’s Thingiverse page has grown to offer 42 3D printable models from its TV properties, including The Expanse, 12 Monkeys and the Killjoys. Not so many: this perfectly reflects that status of “consumer 3D printing” as still a seed with great potential. During the airing of 12 Monkeys Season 3 Event, viewers who owned a 3D printer were urged to download models (in particular the mask from the show’s villain, known as “The Witness” from the Channel’s Thingiverse account.