Additive Manufacturing Technologies (AMT) has received an £87,000 grant from Innovate UK to expand its portfolio of green technology for post-processing 3D printed parts. Innovate UK’s Sustainable Innovation competition was created to help all sectors of the UK recover, grow, and create new opportunities from the aftermath of the global health pandemic.

AMT was awarded £87,000 to fast-track its research and development program to introduce a new generation of green, bio-renewable chemistries designed specifically for post-processing elastomer materials – commonly used for 3D printed PPE and other Covid-19 related respiratory items.

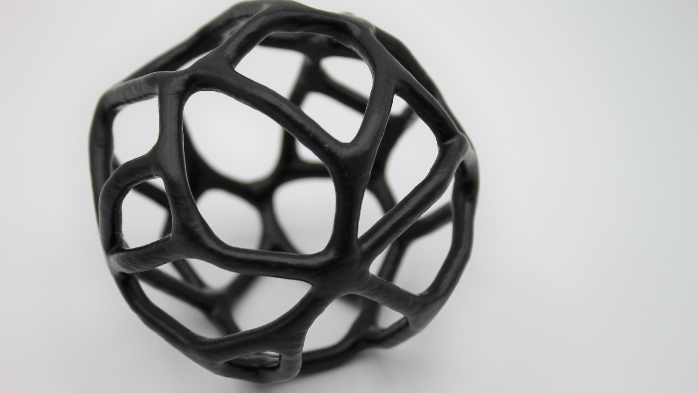

This next-generation consumable is dedicated to TPU, and other elastomer materials, and will be used in AMT’s patented PostPro Chemical Vapor Smoothing process in addition to AMT’s current organic consumable offering.

Manufacturing on Demand

AMT’s patented PostPro Chemical Vapor Smoothing technology allows manufacturers to seamlessly surface finish thermoplastic 3D printed parts for performance-enhanced end-use products. Benefits of the PostPro chemical vapor smoothing process include creating sealed surfaces for highly regulated applications, such as medical, improved mechanical properties for high-performance applications, and improved aesthetics for consumer parts. PostPro technology is compatible with all industry-leading 3D printing technologies and over 100 thermoplastic materials.

“Developing sustainable solutions that further the industrialization of additive manufacturing is our primary focus at AMT, and we’ve already proven that with our PostPro Chemical Vapor Smoothing technology. By utilizing the Innovate UK Sustainability funding to develop this new consumable for elastomers, we’re furthering the capabilities of our technology in an even more sustainable way for our customers” said Dr. Konstantin Rybalcenko, Global Head of R&D at AMT. “We look forward to working with OEM industrial partners to implement this next-generation consumable into 3D printing factories across the globe”.

AMT is currently using next-generation consumables for prototyping. The final product will be globally available in Q2 2021 for companies to innovate and potentially export.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment