Researchers at the Oak Ridge National Laboratory, the largest U.S. Department of Energy (DOE) Open Science Laboratory, have developed Peregrine artificial intelligence (AI) software for powder bed fusion 3D printers without the need for real-time 3D printing quality assessment, used for expensive characterization equipment.

The AI software named Peregrine (probably the name of Peregrine Falcon) has been looking for flaws in 3D printing in real-time.

PEREGRINE AI SOFTWARE

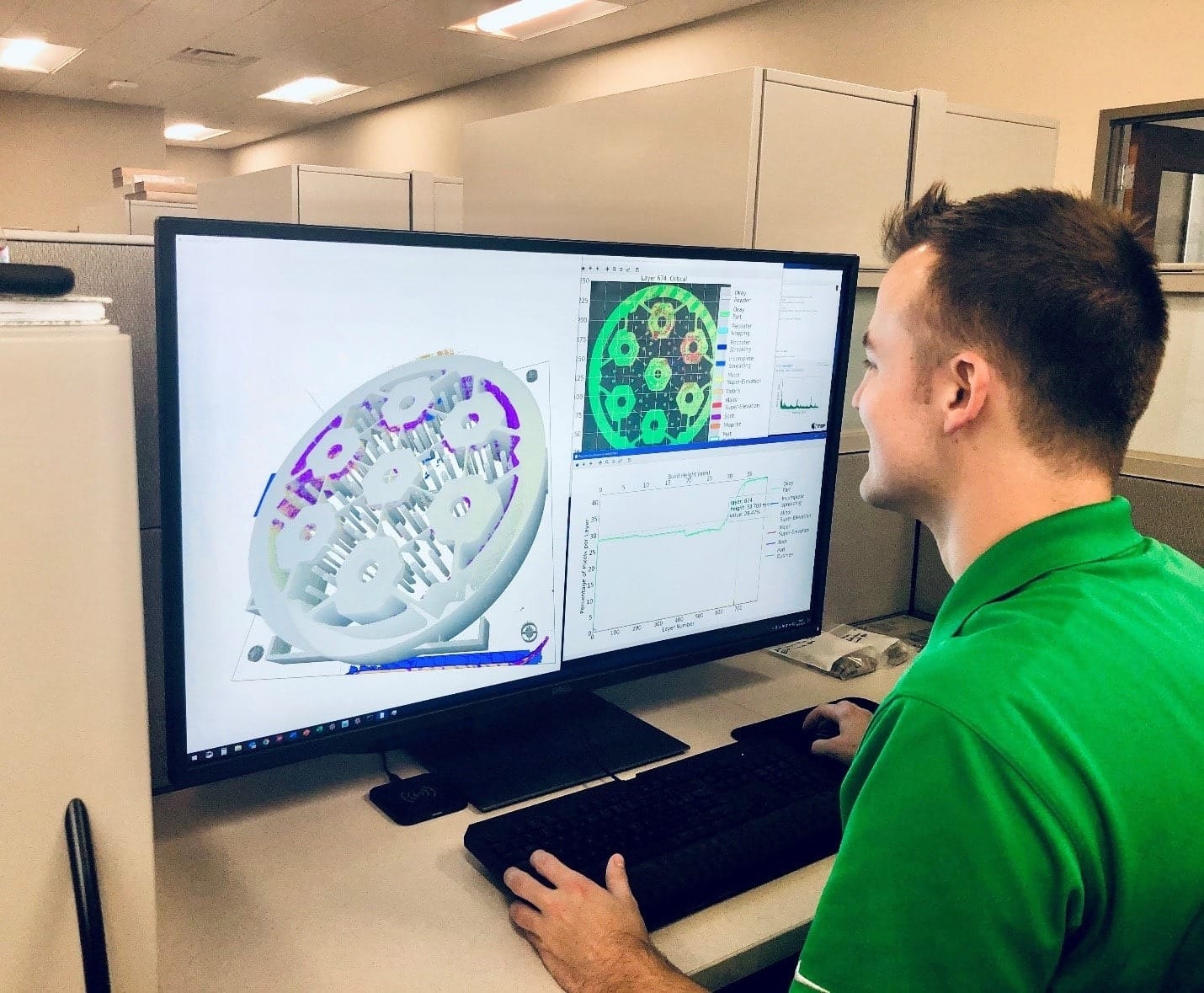

As part of ORNL’s imaging, signal and machine learning group, Vincent Paquit, who leads advanced manufacturing data analysis research, explained: “Capturing information will create a digital “clone” for each part, providing a large amount of data from raw materials to operational parts. We then use this data to identify parts and provide information for future manufacturing across multiple part geometries and multiple materials, thereby achieving a higher level of automation and manufacturing quality assurance.”

Digital threads support the factory of the future, where computer-aided design or CAD is used to design custom parts, and then produced through a self-correcting 3D printer through an advanced communication network. Compared with this, its cost, time, energy and materials are more Less conventional production. This concept requires a process control method to ensure that every part rolled from the printer can be installed in basic applications such as cars, airplanes, and energy facilities.

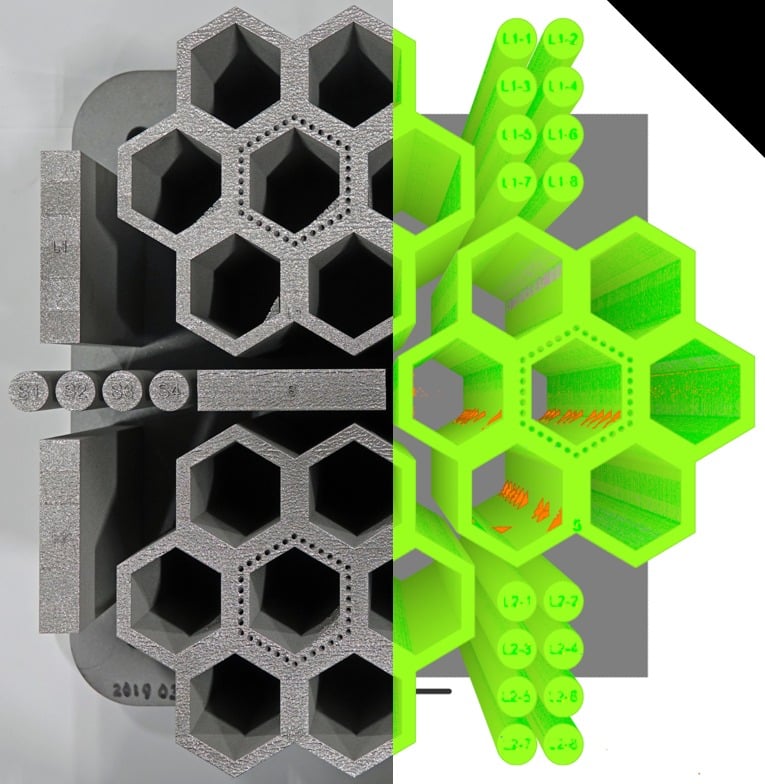

ORNL researchers created a novel convolutional neural network as a control method for controlling visible defects on the surface, which can be used on a variety of printer models. If Peregrine AI software detects an abnormality that may affect the quality of the part, it will automatically warn the operator for adjustment.

The software is very suitable for powder bed printers commonly used for metal 3D printing.

However, during the printing process, problems such as the uneven distribution of powder or binder, splashing, insufficient heat, and some voids can cause defects on the surface of each layer.

According to Luke Scime, principal investigator of Peregrine at ORNL, “One of the basic challenges of additive manufacturing is that you have to care about things that are tens of microns long and that take place in microseconds and last for days or seconds. Weekly build time. Because defects can form at any point at any time, understanding the process and identifying parts becomes a challenge.”

PEREGRINE AI SOFTWARE TESTING

Peregrine AI software has been tested on multiple ORNL printers, including as part of the “Conversion Challenge Reactor” (TCR) and “Demonstration Program”, which is pursuing the world’s first additively manufactured nuclear reactor.

So far, Peregrine AI software has been successfully tested on ORNL’s seven powder bed printers, including electron beam melting, laser powder bed and binder jetting. For more information, please refer to the “Additive Manufacturing” magazine.

ORNL researchers emphasize that by making Peregrine software machine-independent, printer manufacturers can save development time while providing improved products to the industry.

Scime added: “We will do everything we can to help operators and designers know what is effective and what is useless, and are confident that the part can be used. When you have a 3D map of each pixel that the network believes is abnormal and the problem lies, It will open up a world of understanding of the construction process.”

Peregrine AI software was developed by ORNL’s manufacturing demonstration facility, a user facility of the US Department of Energy, which works closely with the industry to develop, test and perfect almost every type of modern advanced manufacturing technology.

This work was sponsored by the Advanced Manufacturing Office of the Office of Energy Efficiency and Renewable Energy of the US Department of Energy and the Office of Nuclear Energy of the US Department of Energy, which provided funding for the TCR program.