After completing the 3D printing of the reefs in the laboratory of the School of Civil Engineering at the University of Cantabria, 3DPARE deployed them on the Atlantic coast of England, France, and Spain. Portugal is next in line.

The 3DPare project has a budget of 1.9 million euros and is funded by the Interreg Atlantic Region Project, which aims to promote innovation and competitiveness, biodiversity, natural and cultural products, and cooperation between the 37 regions of the Atlantic Arc. The consortium is merged by the University of Cantabria and the Caen College of Architectural Engineering, the Portuguese University of Porto, the University of Porto and the University of Bournemouth.

The production of coral reefs poses huge challenges because they are almost one meter long and weigh nearly one ton. Of the 36 works in total, 9 were left in Santander, and the remaining 27 were sent to the project’s three partner centers: the School of Advanced Engineers at Caen University of Architecture, the University of Porto and the University of Bournemouth.

The 36 buildings are now placed on the seafloor of Caen (France), Porto (Portugal), Bournemouth (UK) and Santander, and are followed up by marine biologists who will regularly dive to evaluate new Coral reef biological acceptance.

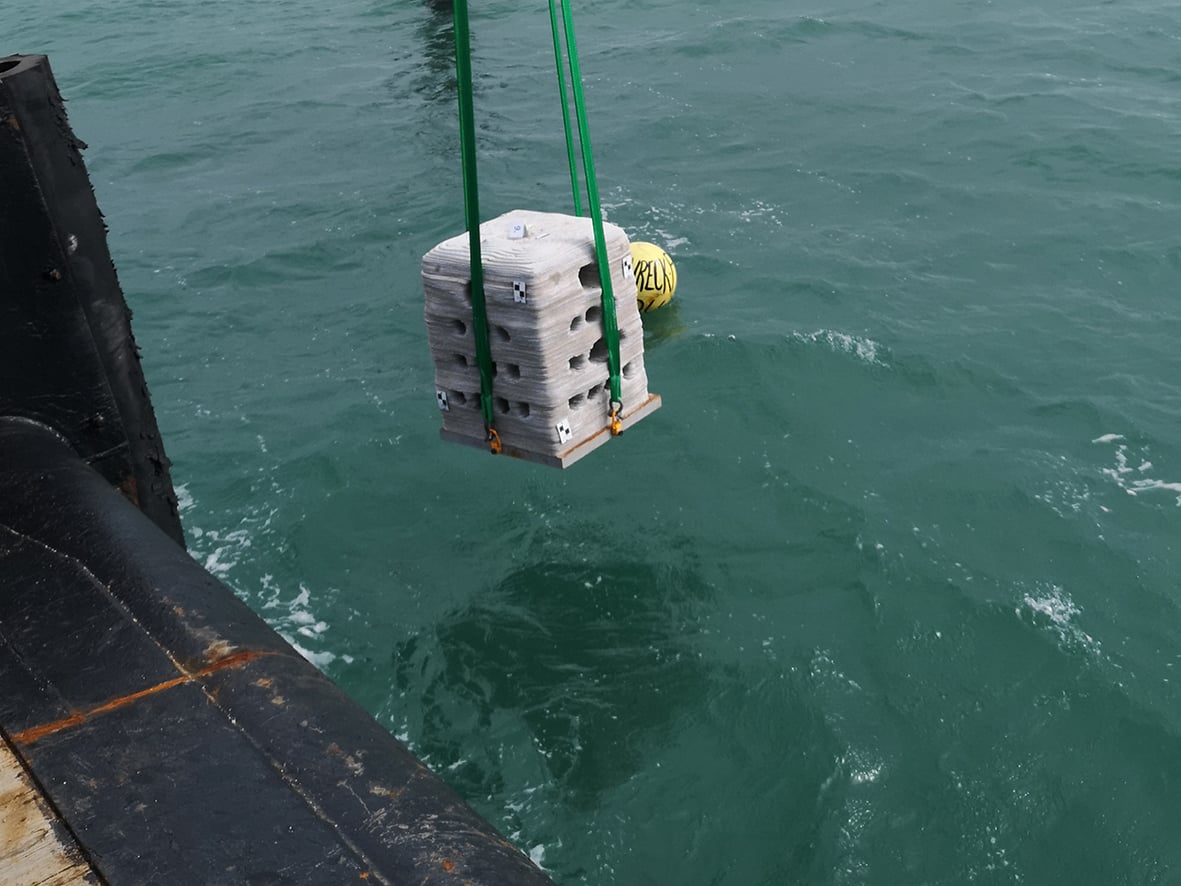

On Tuesday, March 17, Bournemouth University successfully deployed a 3DPARE 3D printed artificial reef unit on the seabed in Poole Bay on the south coast of England. With the help of barges and surface divers, the coral reef unit was placed next to the existing breakwater. There are four artificial reef designs, each of which has been 3D printed in two different concrete mixtures, creating a total of 8 reef units.

All coral reef units contain holes, tunnels, and overhangs, these characteristics provide a suitable habitat for marine life. We also deployed a control unit consisting of a solid concrete cube with a 3D printed surface in one half and a smooth concrete surface in the other half. Place eight artificial reef units and control blocks on a straight line parallel to the breakwater, each separated by 3m.

From May 18 to 19, 2020, Caen ESITC and MNHN cooperated to successfully immerse the 3D printed artificial reef in the bay of Saint Malo (Brittany, France). A total of 8 3DPARE coral reefs were immersed together with one control block. The reef has 2 different designs and concrete formulas, with holes and tunnels. According to the agreement set for the project, it was deployed on a site called FETLAR.

On May 20, the GITECO research team immersed nine artificial reefs in the Gulf of Santander (Cantabria, Spain). A diving team placed nine reefs under the close supervision of Elena Blanco, a UC researcher at GITECO, the University of Cantabria’s applied research group, led by Professor Daniel Castro, next to Torre and Horadada in Magdalena Seabed in front of islets. , From Pedreña Pier. The purpose of the 3DPare project is to study how these reefs promote the restoration of marine biodiversity in degraded marine ecosystems (such as the port environment).

Initially, the researchers studied the most suitable materials based on a total of 150 samples of resistance and printing facilities, identified six best materials, and tested them in Puerto Chico during the soak period. These materials include cement, biopolymers, or aggregates from waste, with the goal of developing more sustainable mortar. The criteria to be considered are cost, medium-term resistance, environmental impact, and adhered biomass.

Coral reefs are the same in 4 positions: 8 types of coral reefs, two types of materials, and 4 different shapes (cubic or random shapes, simulating natural rocks with bulges of different sizes), and two different decorations Surface control parts: smooth or rough. These designs follow biological principles related to cave size in order to enter certain fish species, algae attachment, biological acceptance, etc. The reef manufacturing not only made the work of the 3D printer meet the above standards, but also affected the work of the 3D printer. It is necessary to adapt the printing technology to the corbels, domes, and art galleries that were not fully developed at the time.

After placing coral reef groups, it will take several years to study and monitor the evolution of the results, sample and observe the attractiveness and growth of animals and plants in each group, and finally be able to derive the most suitable materials and shapes for regeneration in four locations Marine life.