US biotechnology start-up Precise Bio has gained the backing of Carl Zeiss Meditec to fund the further development of its 3D printed cornea transplants.

Precise Bio is currently honing endothelial keratoplasty and natural lenticule transplants, designed for treating those patients that suffer from eye conditions like keratoconus and require vision correction. Thanks to Carl Zeiss Meditec’s backing, as well as the synergy between the companies’ offerings, it’s thought that Precise Bio will now be able to accelerate the process of bringing these to market.

“We are very excited with this partnership that builds on our successful, ongoing collaboration with Carl Zeiss (ZEISS) for the development of corneal tissues to address unmet needs in the field of ophthalmology,” said Aryeh Batt, CEO of Precise Bio. “We are confident that the synergy between the two companies will allow us to develop breakthrough solutions for recovering patients’ eyesight, bringing hope to hundreds of millions of patients worldwide.”

“This strategic agreement leverages ZEISS’ global leadership in ophthalmology and Precise’s innovative and unique 4D bio-fabrication platform technology.”

Precise Bio’s bioprinting ambition

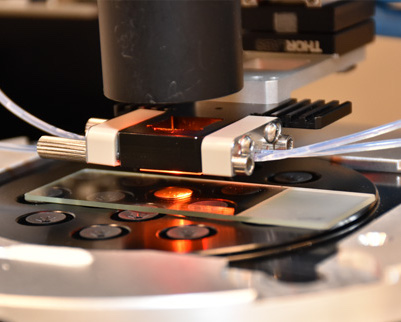

Over the last seven years, Precise Bio has worked towards the development of a precise, practical approach to the biofabrication of transplantable tissues and organs. At the core of the company’s research is the Precise Bio Platform, a bioprinter capable of creating complex organoids at a single-cell resolution in a repeatable fashion.

According to Precise Bio, its technology therefore allows for “rapid innovation and product development,” while “providing a foundation on which a robust pipeline of proprietary products” can be created. Compared to other 3D bioprinting technologies, the firm’s is also said to overcome commonly-faced scalability and repeatability issues, in a way that allows it to address therapeutic R&D needs.

Thus far, the company has primarily used its platform as a basis for developing treatments for eye diseases such as keratoconus, an ailment in which the cornea bulges outward into a cone shape, causing blurred vision and eye sensitivity.

Since late-2018, when Precise Bio set up an ophthalmology business unit, its leading R&D program has focused on the creation of a novel graft, designed to replace the need for donor corneas. Ultimately, working with external partners like ZEISS, the firm says that it aims to develop a bio-retinal patch, capable of treating age-related macular degeneration, but its efforts haven’t yet made it to market.

Zeiss’ medical portfolio expands

In a boost to Precise Bio’s research, it has now gained the backing of Carl Zeiss Meditec, a subsidiary of optical system manufacturer ZEISS. While parent firm ZEISS’ business is primarily focused on the optics and optoelectronics sectors, it has increasingly sought to deploy its expertise in different areas of the 3D printing industry as well.

Manufacturing on Demand

Just last year, ZEISS began working with SENAI and Petróleo Brasileiro to develop 3D printed oil and gas part parameters, before engaging in research with Oak Ridge National Laboratory to advance 3D printed part characterization with AI. More recently, the company has also partnered with Siemens Energy to launch a Makerverse one-stop 3D printing shop, for producing spares or prototypes.

When it comes to ZEISS’ Meditiec subsidiary, meanwhile, the business is more geared towards meeting clinical needs. The firm’s product portfolio covers everything from dentistry to neurosurgery and radiation oncology, but it has established a particularly strong ophthalmology offering. This includes multiple devices designed to facilitate microsurgery like cameras and medical loupes.

Following its investment in Precise Bio, Carl Zeiss Meditec will not only help develop its partner’s bioprinted transplants, but expand this clinical portfolio. Although the financial terms of the deal haven’t been disclosed, it’s understood to give the ZEISS subsidiary exclusive commercialization rights for two products being developed.

“This investment in Precise Bio is expected to complement our leading portfolio of cataract and corneal refractive workflow solutions,” said Euan S. Thomson, PhD, President of Ophthalmic Devices and Head of the Digital Business Unit at Carl Zeiss Meditec. “The technology has the potential to advance treatment options for corneal disease, as well as for elective procedures – further enabling optimization of patient care.”

The 3D printing of artificial eyes

In the absence of a clinically-approved corneal bioprinting process, scientists have also used traditional 3D printing to produce prosthetics, for those whose eyes can’t currently be saved from optical diseases. Late last year, a Londoner named Steve Verze was fitted with the world’s first 3D printed eye prosthetic, in a breakthrough that was hailed as “robust evidence” of the technology’s value in the field.

Additive manufacturing has also been used by some researchers to develop novel approaches to treating eye disorders. Scientists at FabRX, University College London and Spain’s Universidade de Santiago de Compostela, managed to come up with a 3D printed drug-loaded punctal plugs in October 2021, designed for insertion into the tear duct of an eye to block it and prevent liquid drainage.

Similarly, researchers at the University of Basel have 3D printed a socket fracture implant that carries a reduced risk of patient rejection. Made using a Prusa i3 3D printer and PEEK filament, the team’s grafts are said to have porous features which enable them to overcome bioinertness and enhance cellular repair.

.

You might also like:

Triastek and Eli Lilly partner to 3D print gastrointestinal drugs: Specifically, the project will leverage Triastek’s proprietary Melt Extrusion Deposition (MED) technology to fabricate programmed drug release profiles to target specific areas of the human digestive system.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment