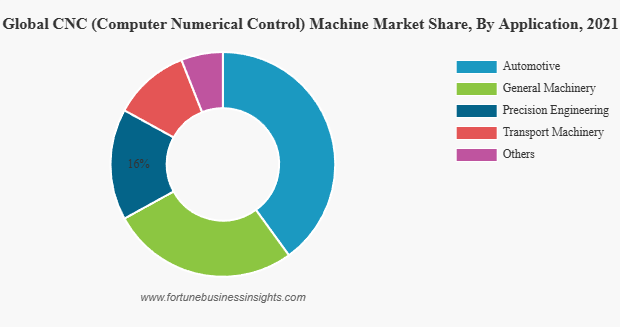

CNC machining is a process that uses computer-controlled machines to create precise and complex parts from various materials. CNC machining is widely used in various industries, such as automotive, aerospace, electronics, and medical. CNC machining is expected to grow at a compound annual growth rate (CAGR) of 10.3% from 2023 to 2030, reaching USD 127.0 billion by 2032.

The growth of CNC machining is driven by several factors, such as:

- The increasing demand for high-quality and customized products, especially in the aerospace, military, and medical sectors, where precision and accuracy are crucial. CNC machining can offer high precision, speed, efficiency, and flexibility, reducing human error and labor costs.

- The technological advancements in CNC machines and software, such as more axes, smart technology, additive manufacturing, and automation. These technologies can enhance the capabilities, performance, and productivity of CNC machines, enabling them to execute complex tasks with fewer setups and less waste.

- The integration of Internet of Things (IoT) technology and Artificial Intelligence (AI) in CNC machines and software, which can enable predictive maintenance, adaptive machining, and data-driven optimizations. These technologies can improve the reliability, quality, and creativity of CNC machining, as well as reduce downtime and operational costs.

- The development of online courses, virtual reality simulations, and augmented reality applications to train and certify CNC machinists. These methods can provide more accessible, flexible, and interactive learning experiences for aspiring and existing CNC machinists, addressing the skill gap and labor shortage in the CNC industry.

- As the market of 3D printing is saturated and in a price war, and the threshold for the CNC machining industry is higher than the 3D printing industry, more companies are turning to offer CNC machining services in China. With the experience of both industries, companies like FacFox could offer the best solution for your requirements, making idea realization easier.

However, there are also some challenges and uncertainties that may affect the growth of CNC machining, such as:

- The high initial investment and maintenance costs of CNC machines and software, which can create a financial barrier for some customers, especially small and medium-sized enterprises (SMEs) with constrained budgets. The high capital expenditure associated with CNC machines may restrict their widespread adoption in some industries or regions.

- The fluctuations in raw material prices and the shortage of semiconductors used in CNC machines, which can increase the production costs and reduce the supply of CNC machines. These factors can affect the profitability and competitiveness of CNC machine manufacturers and customers.

- The economic uncertainties and the possibility of a recession, which can reduce the demand and spending for CNC machines and products. The CNC industry may face a slowdown or a decline in orders and revenues, especially from sectors that are sensitive to economic cycles, such as automotive and construction.

Therefore, the CNC machining market trend for 2023 is expected to be positive, but cautious. CNC machining will continue to be a vital and innovative process for various industries, but it will also face some challenges and risks that may hinder its growth potential. CNC machine manufacturers and customers will need to adapt to the changing market conditions and leverage the opportunities and advantages that CNC machining can offer.

If you are looking for a reliable and professional CNC machining service provider, look no further than FacFox. FacFox is a leading online platform that offers high-quality and affordable CNC machining services as well as 3D printing services for various industries and applications. Whether you need a prototype, a small batch, or a large-scale production, FacFox can handle it with ease and efficiency.

We can work with a wide range of materials, such as metals, plastics, wood, and composites. We can also offer various finishes, such as anodizing, painting, powder coating, and polishing. FacFox uses the latest CAD/CAM software and 3-axis, 4-axis and 5-axis machines to ensure the accuracy and quality of your parts. FacFox can also provide you with design assistance, engineering support, and quality inspection. Contact us via info@facfox.com today!

Leave A Comment