- SLA 3D Printed Hand Painted Realistic Miniature Patio

- Full-Color 3D Printed Board Game Miniatures and Terrain Models

Material Resin

Quantity 4 pcs

Price Range $1-100

Lead Time 3 workdays

Gallery

About Project

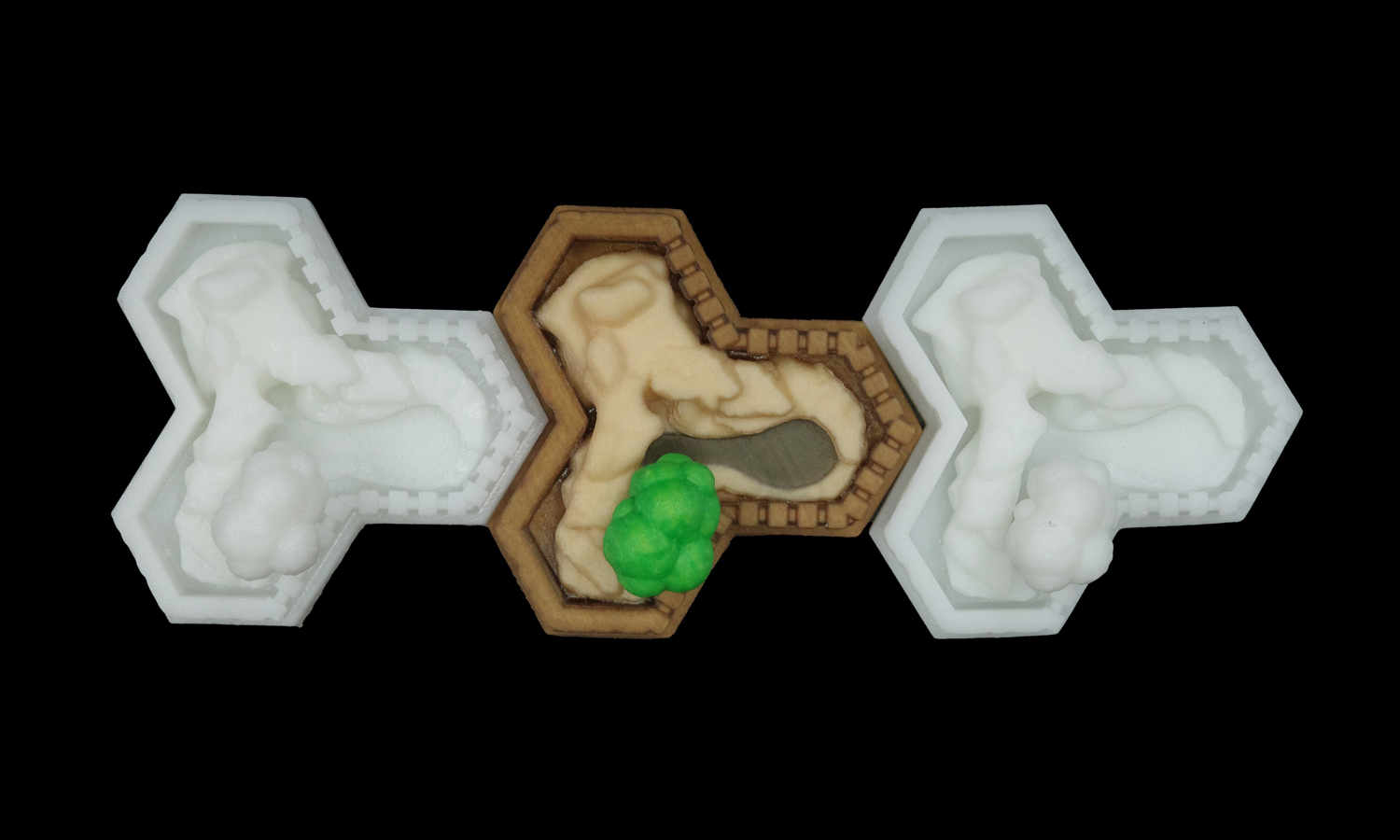

This project features a set of miniature terrain tiles and character heads designed for a board game, showcasing both full-color WJP printing and SLA resin printing. The full-color versions were produced to visualize the game’s world vividly, while SLA versions provided a cost-effective alternative for prototyping and painting.

Full-Color Version – WJP 3D Printing

The original models were produced using Full-Color Material Jetting (WJP) technology. Each tile represents an intricate miniature landscape with realistic rock textures, water surfaces, and greenery, while the character heads capture subtle skin tones and hair gradients.

In this process, the printer jets and cures pigmented photopolymer droplets layer by layer, blending CMYK colors to reproduce detailed digital textures. The result is a model that comes directly off the printer with lifelike colors and fine surface detail – no painting required.

Advantages:

- True full-color gradients and fine texture reproduction

- Ideal for visual prototypes and display models

- Eliminates manual painting steps

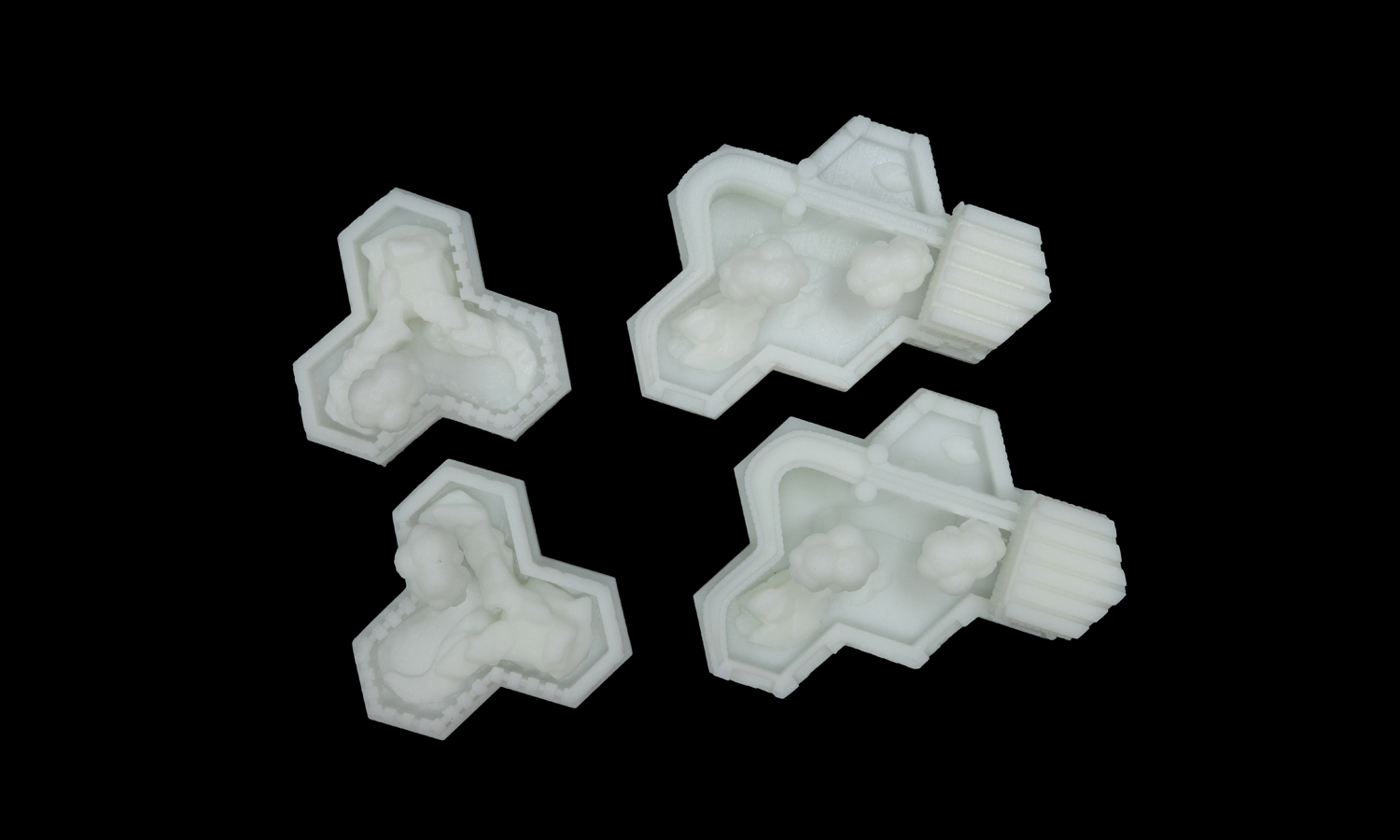

White Versions – SLA 3D Printing

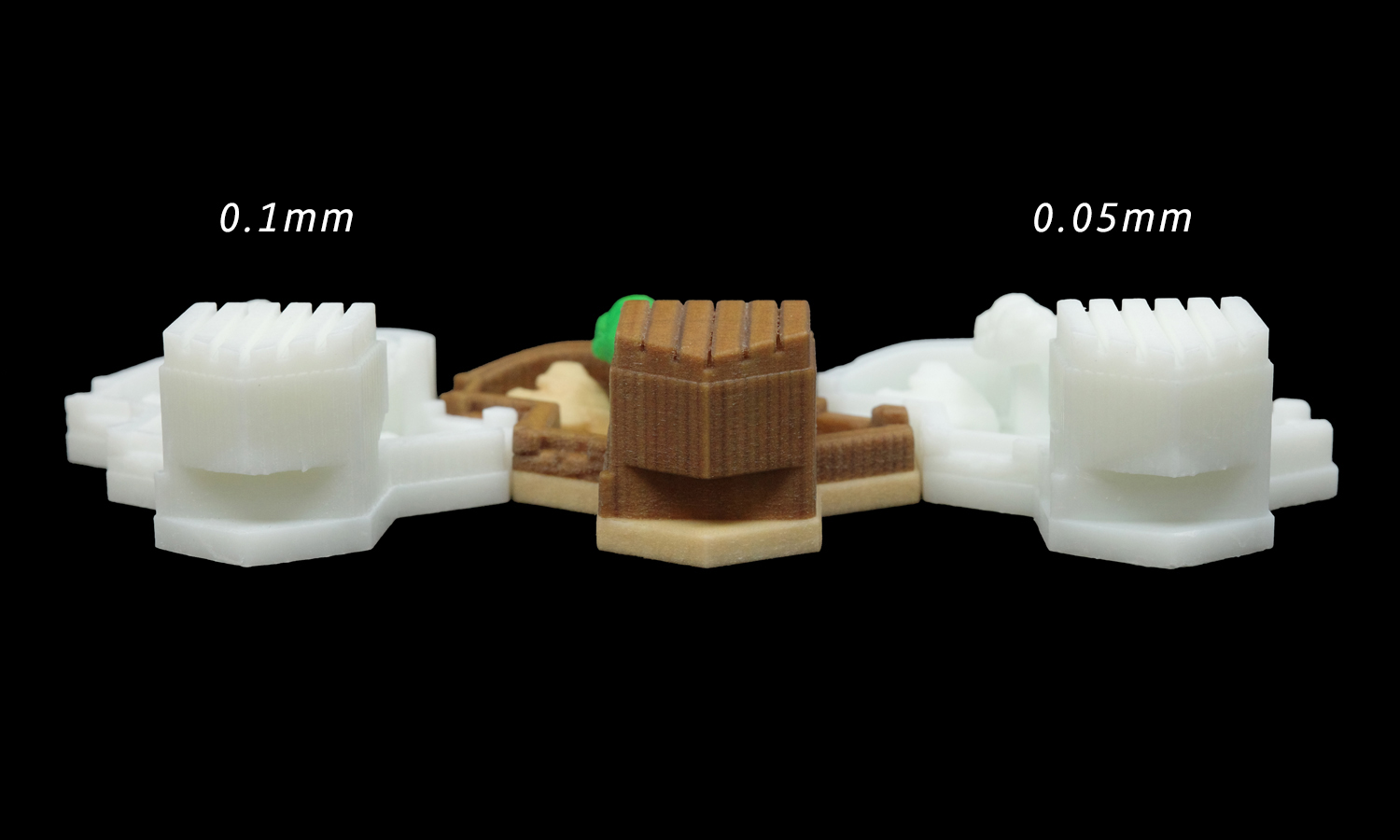

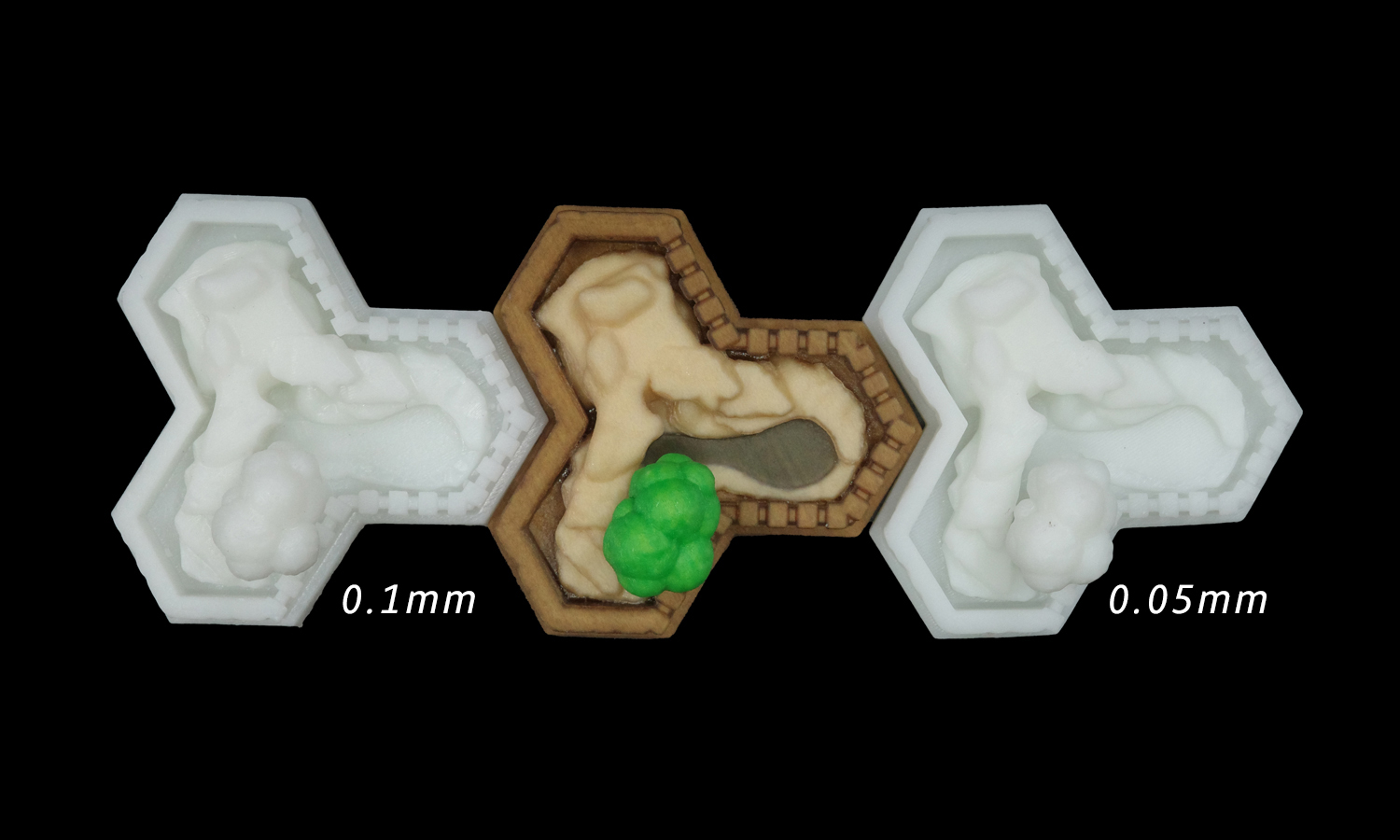

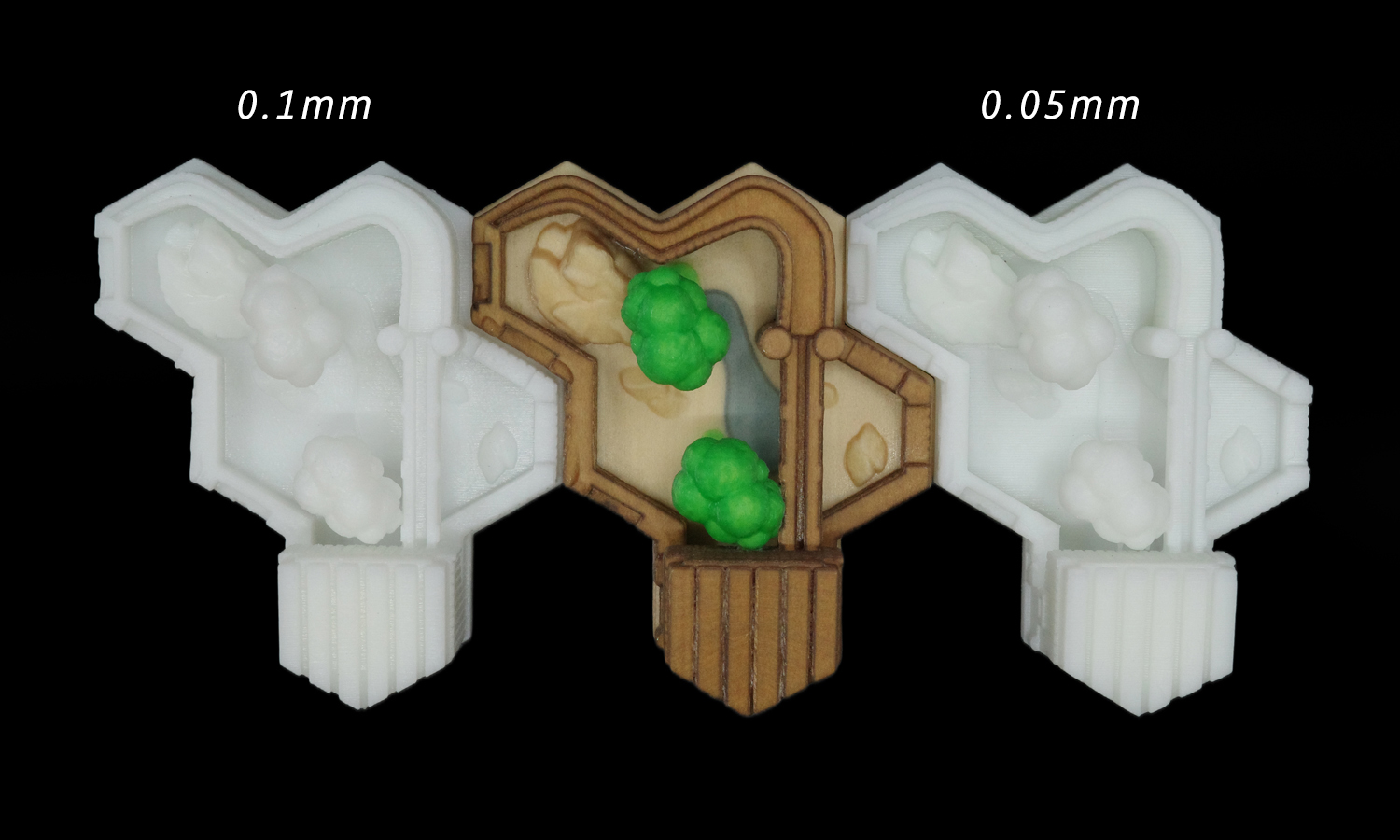

To reduce production costs, the client also requested duplicates printed with SLA (Stereolithography) technology in SLA Generic Resin, using two different layer resolutions.

- Left model: 0.1 mm layer thickness – slightly glossier due to more pronounced layer lines, which reflect light more easily.

- Right model: 0.05 mm layer thickness – smoother and more matte, with finer surface transitions.

The difference between the two resolutions is barely visible in photos, but becomes much clearer after painting. The 0.05 mm layers provide a superior surface for achieving realistic painted finishes, while the 0.1 mm setting balances quality and speed for faster prototyping.

Advantages:

- Cost-efficient compared to full-color printing

- Excellent for painting and finishing work

- Flexible print resolution for different needs

Bring Your Game to Life with FacFox

FacFox offers professional full-color and resin 3D printing services for board games, collectible figurines, and creative prototypes. With WJP, SLA, and PolyJet technologies, we can reproduce lifelike textures, vivid colors, and crisp details – from concept to finished miniature.

Whether you need a display-ready model or a paintable blank, FacFox helps bring your imagination to life.

Solution

- Step 1: Model Preparation. The 3D models were carefully inspected for watertight geometry and proper wall thickness suitable for SLA printing. Supports and drainage holes were planned to ensure stability and efficient resin curing.

- Step 2: Slicing and Parameter Setup. The files were sliced with two different resolutions – 0.1 mm and 0.05 mm layer thickness – using FacFox’s optimized SLA printing profiles. The lower resolution (0.05 mm) was selected for higher surface smoothness, while 0.1 mm provided faster build time for cost-effective production.

- Step 3: Printing. The models were printed with Generic Resin on an industrial SLA printer. A UV laser selectively cured liquid resin layer by layer, solidifying the fine details of rocks, walls, and terrain textures.

- Step 4: Post-Printing Cleaning. After printing, each part was removed from the build platform and rinsed thoroughly in isopropyl alcohol (IPA) to dissolve uncured resin. Supports were detached carefully to avoid surface damage.

- Step 5: UV Curing. The cleaned models were placed in a UV curing chamber to complete polymerization and reach full mechanical strength. This step also stabilized the surface for consistent gloss and dimensional accuracy.

- Step 6: Surface Refinement. Support marks and minor ridges were lightly sanded. The 0.05 mm version showed smoother transitions, while the 0.1 mm version retained subtle layer reflections that created a slightly glossier appearance.

- Step 7: Quality Inspection. Each model was examined for dimensional accuracy, warping, and surface finish. Both versions achieved high precision