Gallery

About Project

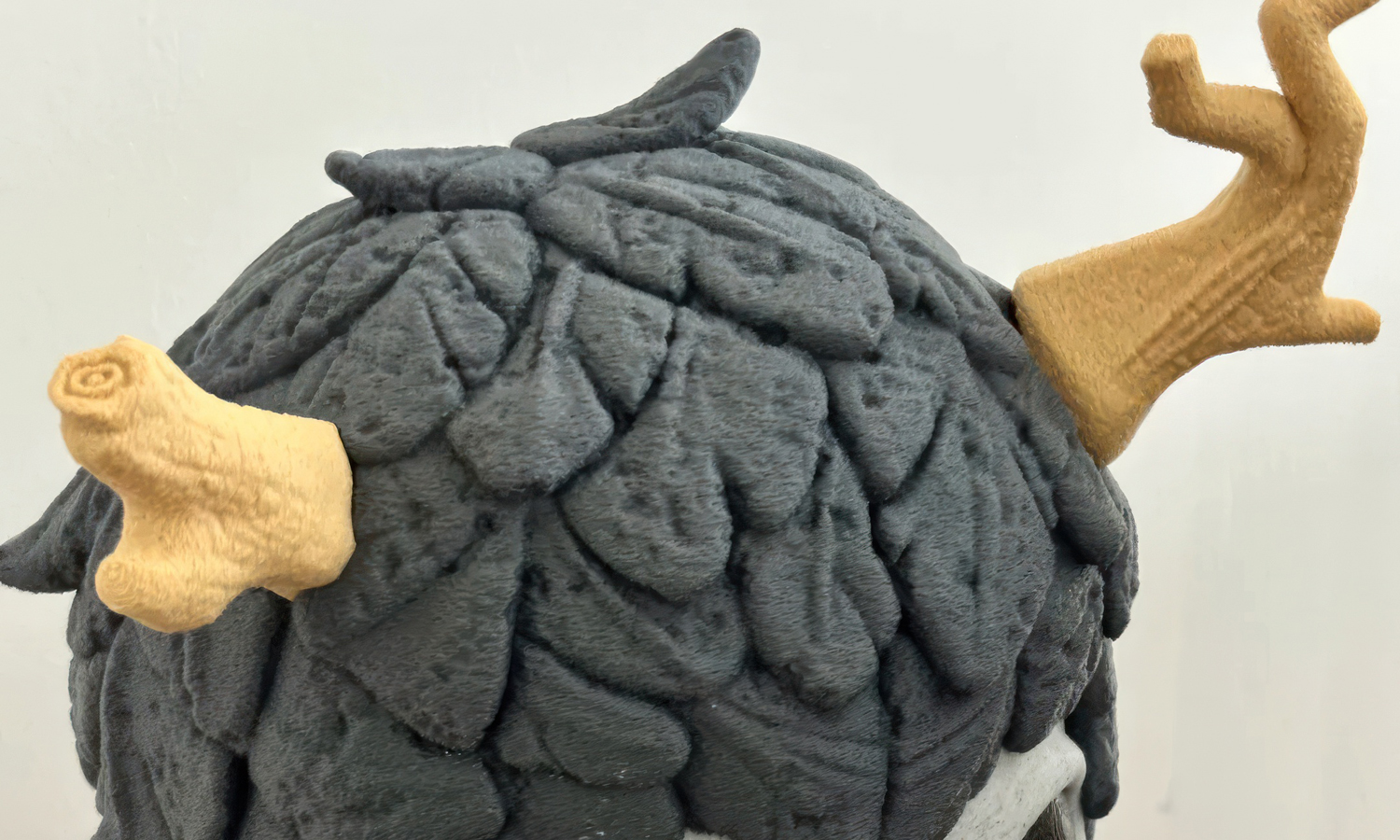

Meet this hauntingly adorable Hirono Birdy statue, a fusion of cuteness and eerie mystique. Designed with a layered feathered cloak, solemn expression, and standing atop a bed of skulls, this collectible toy sculpture blurs the line between fantasy and dark folklore.

This figure was 3D printed using a Bambu Lab 3D printer, utilizing the Fuzzy Skin mode to give the feathers and cloak a tactile, organic texture that mimics rough sculpted stone or carved wood. The fine detailing of the feathers and the antler-like horns shows how effective this mode is in adding depth and realism to stylized designs.

To make the face stand out, a marble-like PLA filament was chosen, lending it a smooth, pale ceramic finish that contrasts beautifully against the rougher, darker surface of the cloak. The antlers on top were printed in a warm beige tone, adding a natural, wooden accent to the character.

FDM printing might not be the first choice for fine art statues, but with the right settings-like Fuzzy Skin, proper support placement, and smart color separation-it’s possible to achieve results that rival resin prints in style and presence.

Solution

- Step 1: The 3D model of the Hirono Birdy statue was prepared using slicing software compatible with the Bambu Lab 3D printer. The statue was segmented by material color to optimize multi-material printing.

- Step 2: Fuzzy Skin mode was enabled in the slicer settings to apply a textured surface to the cloak and body, simulating a rough, feather-like finish. Custom surface settings were adjusted to enhance the organic texture.

- Step 3: Multiple filaments were loaded into the AMS (Automatic Material System) of the Bambu Lab printer. A dark matte filament was used for the feathers, a marble-textured PLA for the face, and a light beige filament for the antlers.

- Step 4: The print job was initiated, and the statue was fabricated layer by layer using Fused Deposition Modeling (FDM) technology. The marble face and antlers were automatically switched using the AMS system without manual intervention.

- Step 5: After printing, the model was allowed to cool completely on the build plate to avoid warping or cracking, especially due to the varied filament materials.

- Step 6: Supports and brim were carefully removed by hand to preserve surface details. Any minor strings or artifacts were trimmed using a precision knife.

- Step 7: The surface was lightly brushed and dusted, but no post-processing like sanding or painting was applied in order to preserve the raw FDM textures-especially the fuzzy skin finish.

- Step 8: The final piece was inspected for structural integrity, color alignment, and detail resolution, then displayed as a finished collectible sculpture.