- FDM 3D Printed Vase Using Upcycled Iron for Balance

- FDM 3D Printed PETG Shell Replacement for Logitech Master 3

Material Plastic

Quantity 8 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

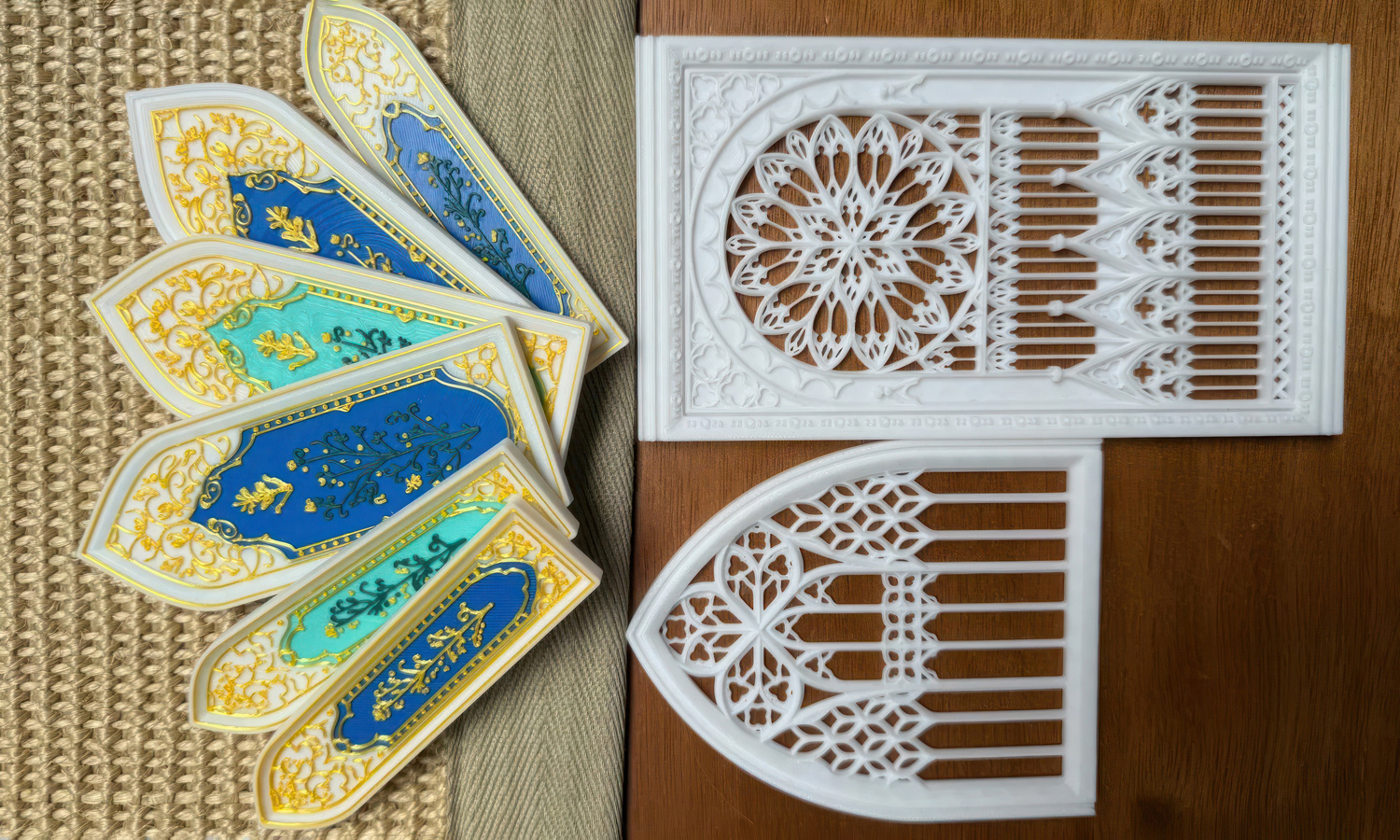

These miniature church windows are a perfect blend of historical elegance and modern craftsmanship, designed specifically for dollhouse scenery. Each piece has been 3D printed with stunning architectural precision, bringing the grandeur of cathedral windows down to dollhouse scale.

On the left, the colorful stained-glass inspired panels incorporate Middle Eastern and Islamic motifs, complete with delicate floral patterns and golden Arabic calligraphy. They radiate warmth and cultural charm, ideal for adding exotic flair to miniature settings.

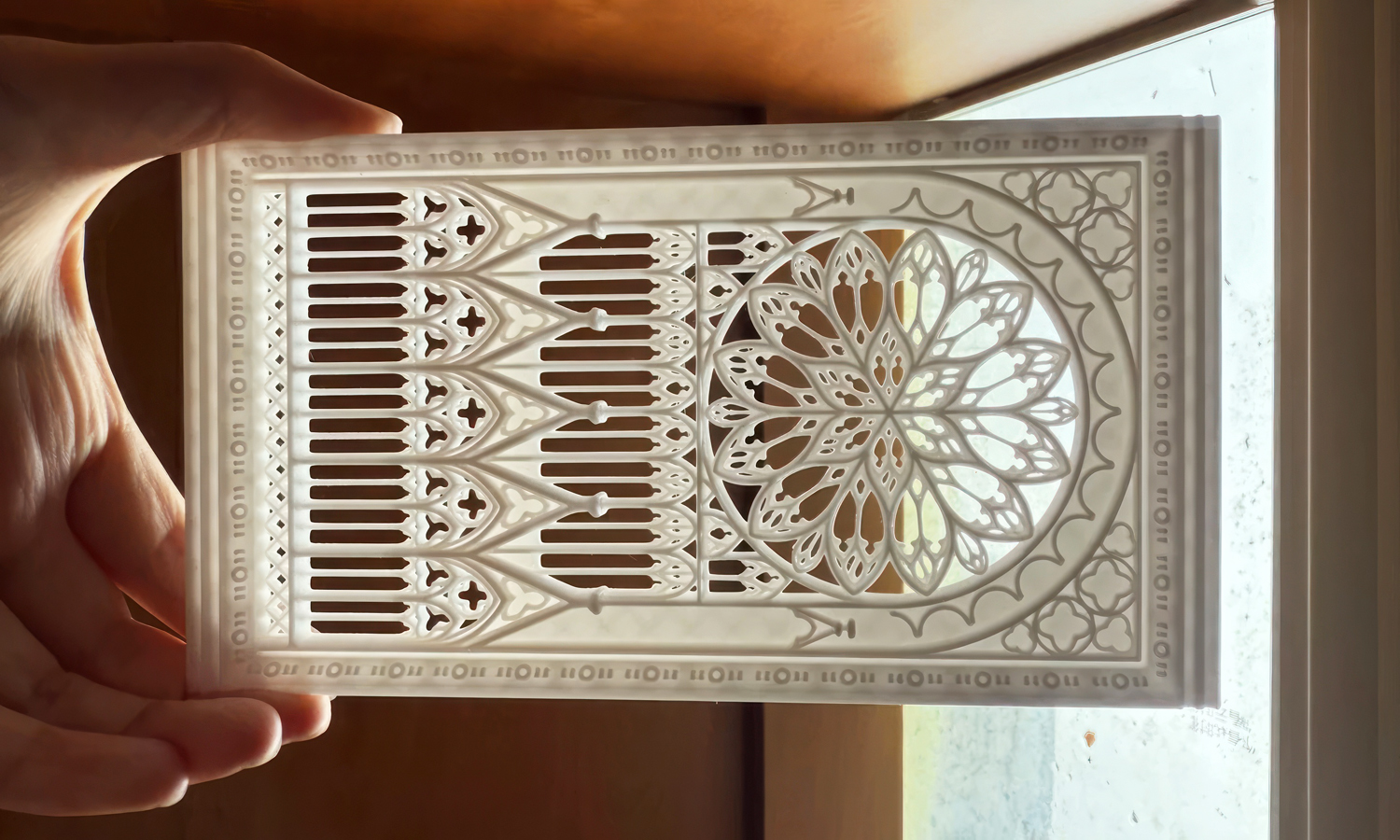

On the right, the all-white Gothic-style windows capture the intricate tracery and rose window design found in classic European cathedrals. The sharp detailing of spires and arches makes them a standout background element for miniature chapels, castles, or fantasy scenes.

Whether you’re building a majestic dollhouse interior or crafting a historical diorama, these 3D printed pieces offer unmatched flexibility and visual appeal.

FacFox offers custom 3D printing services for miniatures, dioramas, and dollhouse decor. From color-rich multi-material printing to high-resolution architectural detailing, we help bring your creative visions to life. Whether you’re a collector, modeler, or designer-3D printing might just be the most efficient way to produce beautiful and intricate components for your small-scale world.

Solution

- Step 1: The 3D models of the church windows were designed using CAD software, incorporating both Gothic tracery and Middle Eastern decorative motifs.

- Step 2: The digital files were sliced using slicing software compatible with multi-color FDM 3D printers. Separate toolpaths were generated for different filament colors.

- Step 3: Multi-color PLA filaments were loaded into an FDM 3D printer capable of color switching, such as a Bambu Lab or Prusa with MMU system.

- Step 4: The printing process was initiated. Each layer was precisely deposited using fused deposition modeling (FDM) technology, with color changes occurring at programmed intervals to form the ornate patterns and calligraphy.

- Step 5: The prints were carefully removed from the build plate once cooling was completed to prevent warping or layer separation.

- Step 6: Support structures, if any, were removed by hand or with tools. The models were then inspected for surface artifacts and cleaned accordingly.

- Step 7: For the colored panels, any fine details were further highlighted using hand painting or filament-based embellishment to enhance visual clarity.

- Step 8: All finished window models were arranged for assembly or display, ready to be used in dollhouse scenery and miniature diorama construction.