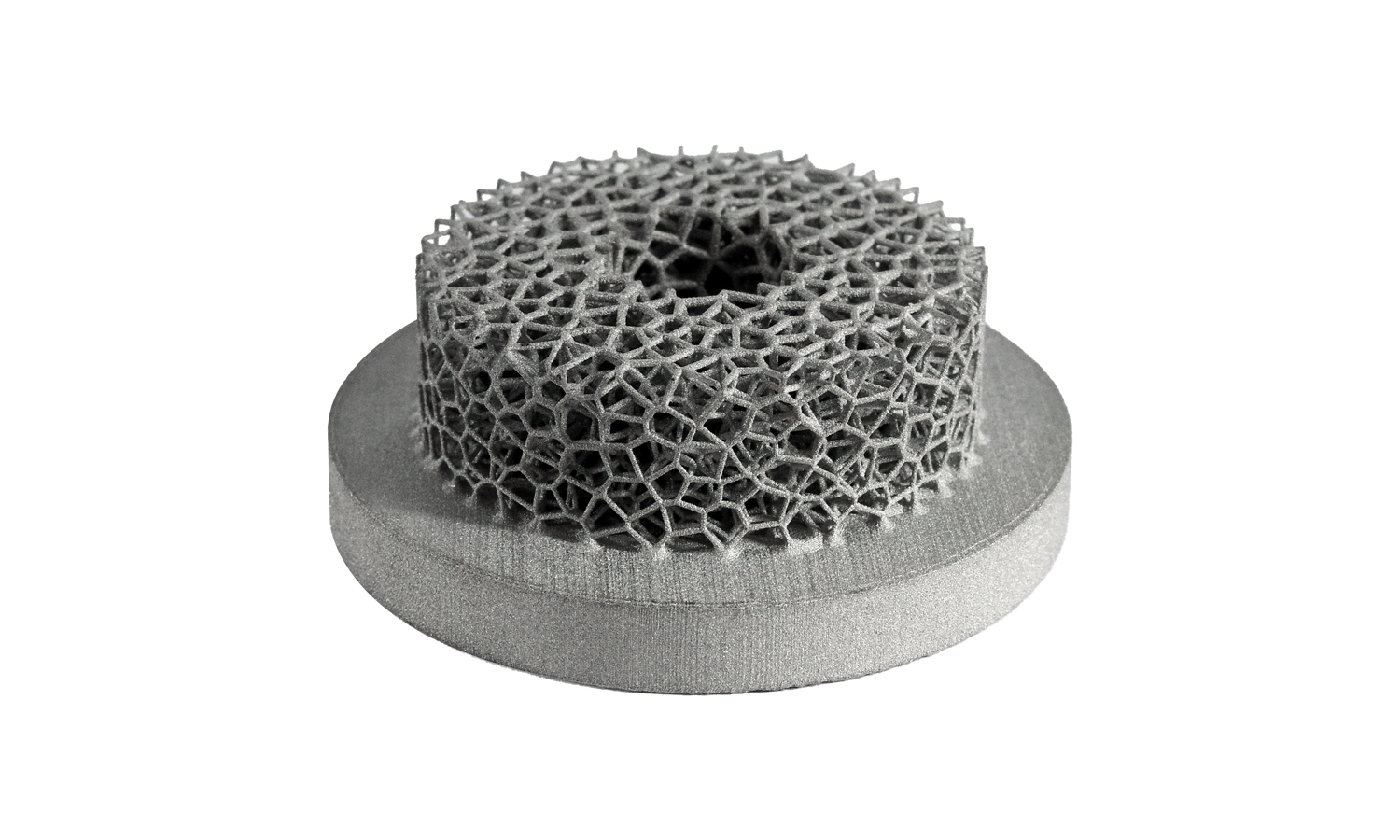

BinderJet 3D Printed SS316L Lattice Hybrid Structure

- BinderJet 3D Printed SS316L Ring with Triangular Facets

- BinderJet 3D Printed SS316L Interwoven Sphere Sculpture

Posted on 2024-11-29 in Medical ┬Ę Õī╗ń¢Ś

Gallery

About Project

This stunning 3D-printed SS316L lattice hybrid structure showcases the incredible capabilities of BinderJet 3D printing technology. The intricate design, combining a smaller ring with a larger disc, is a testament to the precision and complexity achievable through additive manufacturing.

Key Features

- Hexagonal Honeycomb Lattice: The disc's pronounced hexagonal honeycomb pattern offers exceptional strength-to-weight ratio, making it ideal for applications requiring high structural integrity and minimal weight.

- Intricate Sponge-Like Lattice: The ring's intricate sponge-like structure provides a high surface area-to-volume ratio, perfect for applications like filtration, heat exchange, or sound absorption.

Potential Applications

The versatility of this hybrid structure opens up a world of possibilities across various industries:

- Aerospace: Lightweight, high-strength components for aircraft and spacecraft.

- Automotive: Innovative designs for fuel-efficient and high-performance vehicles.

- Biomedical: Implantable devices with intricate structures for tissue engineering and drug delivery.

- Energy: Efficient heat exchangers and energy storage solutions.

Experience the Future of Manufacturing with FacFox

FacFox is your trusted partner in metal 3D printing. Our state-of-the-art BinderJet technology and expert team can bring your complex designs to life. From prototyping to production, we offer a wide range of metal materials and finishing options to meet your specific needs.

Contact us today to explore the possibilities of 3D printing with FacFox.

Solution

- Step 1: Design.┬ĀThe design of the SS316L Lattice Hybrid Structure was created using CAD software. The design included a combination of a smaller ring and a larger disc, each with distinct lattice patterns.

- Step 2: Slicing.┬ĀThe CAD model was sliced into thin layers using slicing software, preparing it for 3D printing.

- Step 3: Preparation.┬ĀThe SS316L stainless steel powder was prepared and loaded into the BinderJet 3D printer.

- Step 4: Printing.┬ĀThe printer spread a thin layer of stainless steel powder over the build platform. A binding agent was then selectively applied to the powder, bonding the particles together layer by layer to form the desired shape.

- Step 5: Layering.┬ĀThe process of spreading powder and applying the binder was repeated until the entire object was built up from individual layers.

- Step 6: Curing.┬ĀThe printed part was allowed to cure, allowing the binder to harden and stabilize the structure.

- Step 7: Unpacking.┬ĀThe object was carefully removed from the powder bed, and any excess powder was brushed off and recovered for future use.

- Step 8: Sintering.┬ĀThe object was placed in a sintering furnace, where it was heated to a high temperature to fuse the stainless steel particles together, achieving the final density and strength.