- UPDATE: Order lists can be displayed for now, but we are still debugging. During that period there might still be problems.

- „ÄêIssue Alert„ÄëSite experiencing a technical issue (order lists not displaying), we are working on it!

Gallery

About Project

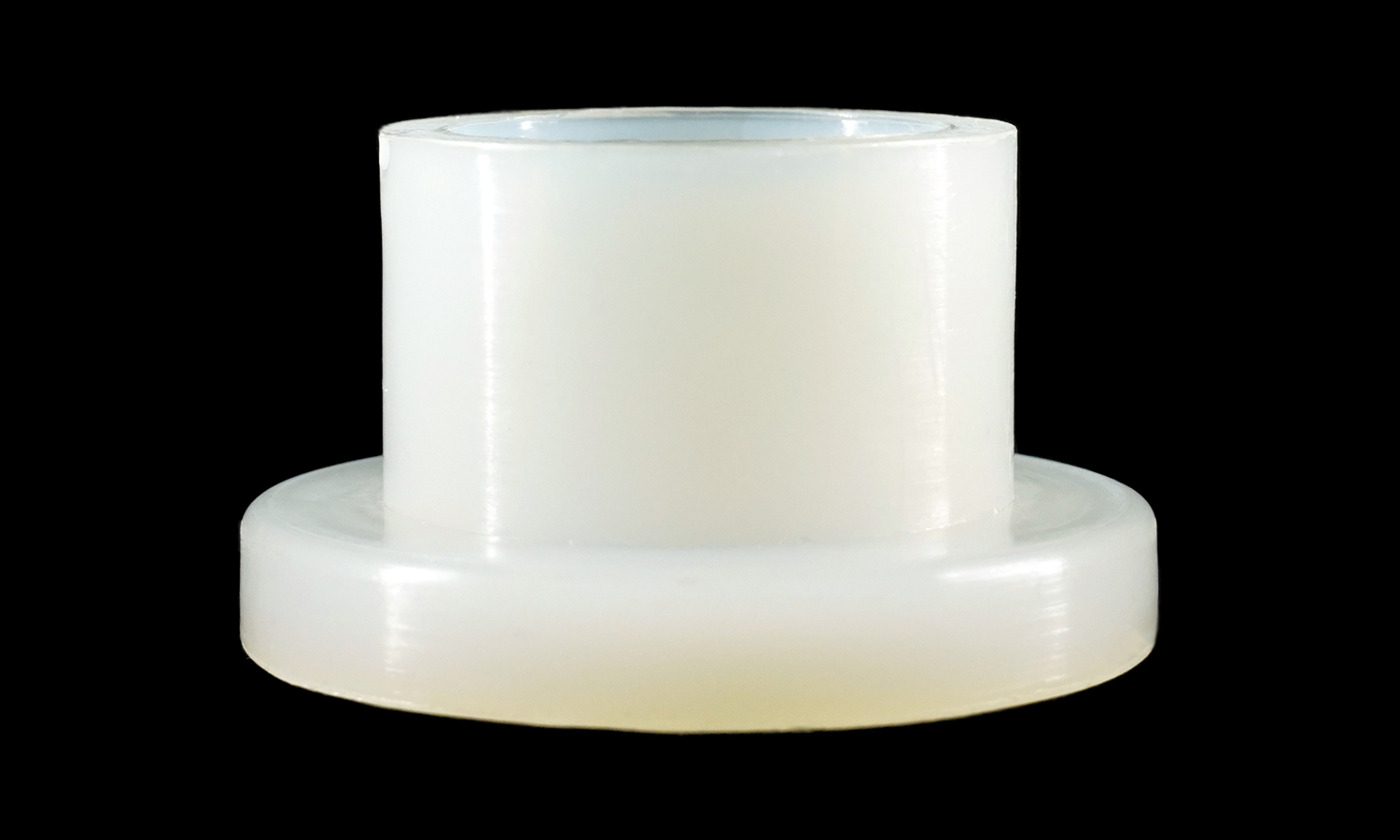

Are you looking for a reliable and durable solution for your bearing needs? If so, you might want to consider PU bearing bushing flanged sleeves. These are a type of plastic flanged bushings that are made of polyurethane (PU), a versatile material that has excellent abrasion resistance, impact strength, elasticity and low-temperature flexibility.

Spin cast PU bearing bushing flanged sleeves have several advantages over other types of flanged bushings. They help reduce vibration and noise using a sliding motion, that absorbs friction between moving parts. They have a translucent milk white color that allows for easy visual inspection of the bushing condition and lubrication level. They have a high load-bearing capacity and can withstand shock loads and dynamic stresses. They have a low coefficient of friction and good wear resistance, which reduces the need for maintenance and replacement. They have good chemical resistance and can operate in harsh environments with exposure to water, oil, grease, solvents and acids. They have good dimensional stability and can tolerate misalignment and edge loading. They have good thermal conductivity and can dissipate heat efficiently.

Spin cast white PU bearing bushing flanged sleeves can be used in a wide variety of applications in industry, agriculture and transport. Some examples are agricultural machinery, conveyor systems, hydraulic pumps, electric motors, textile machines, printing machines, packaging machines, food processing machines and more.

If you are interested in spin cast white PU bearing bushing flanged sleeves, you might want to check out FacFox’s PU spin cast services. FacFox is a leading provider of custom-made PU products with high quality and competitive prices. FacFox can spin cast any shape and size of PU bushings according to your specifications and requirements. FacFox also offers fast delivery and excellent customer service. To learn more about FacFox’s PU spin cast services, please visit their website at https://www.facfox.com/ or contact them at info@facfox.com.

Solution

- Step 1: a pattern of the desired bushing shape and size was made using 3D printing technique.

- Step 2: the pattern was placed between two discs of uncured rubber and the mold was formed.

- Step 3: the mold was loaded into a vulcanizer that applied heat and pressure to cure the rubber.

- Step 4: it was then loaded into a spin casting machine and spun along its central axis at a set speed.

- Step 5: molten PU was poured into the mold through an opening at the top-center while the mold was spinning.

- Step 6: the PU solidified into the shape of the bushing as the centrifugal force pulled it into the cavities.

- Step 7: the mold was removed from the spin casting machine and the PU bushing was extracted from the mold.