- DLP 3D Printed Delicate Dagger Blade and Extension Rod

- SLA 3D Printed Clear Resin Mini Chubby Motorcycle

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 11 workdays

Gallery

About Project

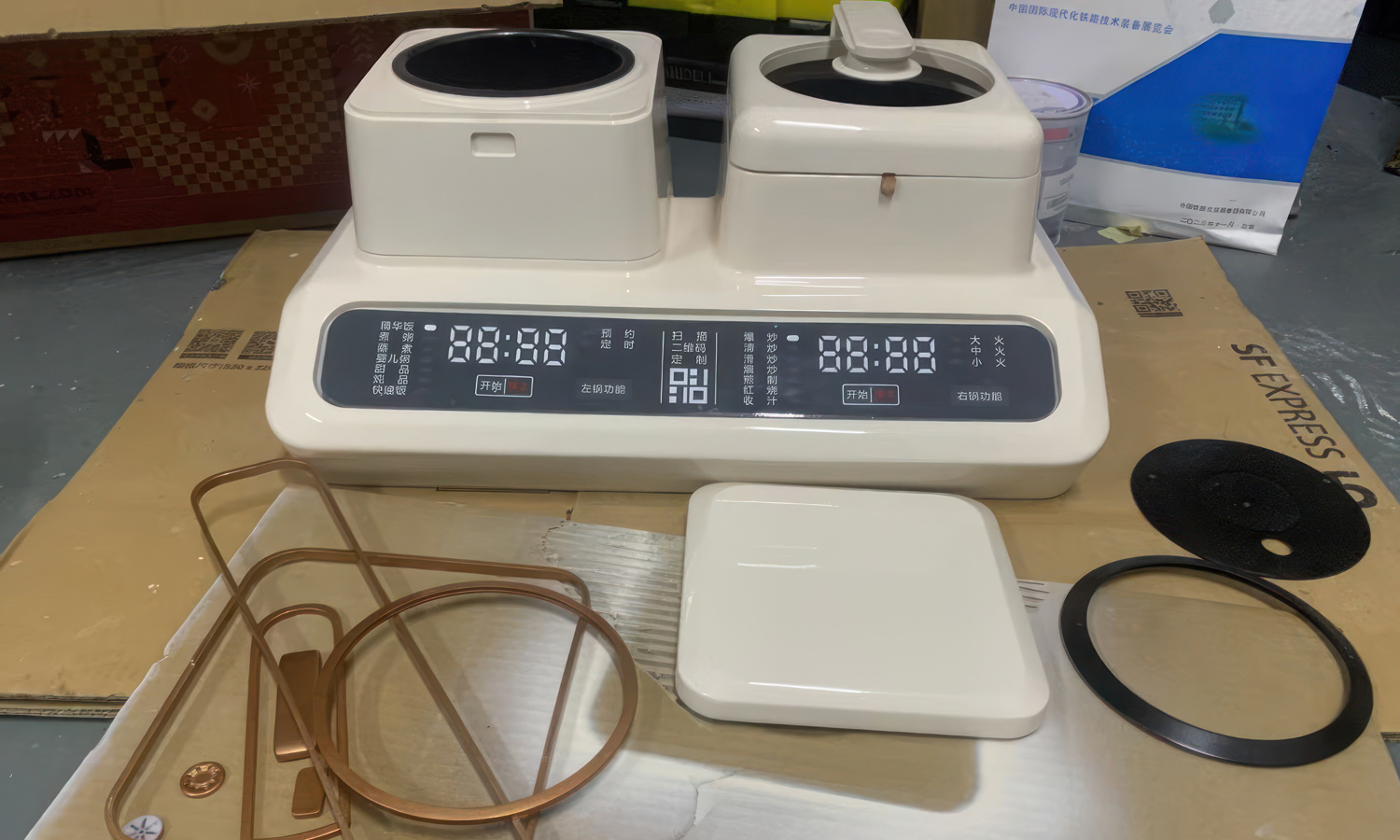

This innovative SLA 3D printed multi-function cooking machine prototype is a glimpse into the future of home appliances. With its heating base, digital display, and control buttons, this machine promises to simplify and streamline your cooking experience.

The base of the machine can heat the pots and has various settings to choose from, likely including modes for boiling, steaming, and frying. The two pots, with their square shape and round corners, offer versatility for different cooking tasks. The left pot appears ideal for steaming or boiling, while the right pot features an automatic stirring mechanism that rotates food for even cooking.

While this prototype is not yet functional, it showcases the exciting potential of 3D printing for home appliance design. FacFox offers SLA 3D printing services that can help you bring your own innovative home appliance ideas to life. With SLA printing, you can create high-resolution, precise prototypes that are perfect for testing and iterating on your designs.

FacFox’s SLA 3D Printing Services for Home Appliances

FacFox is a leading provider of SLA 3D printing services, and we are experts in helping businesses and entrepreneurs bring their home appliance ideas to life. Our SLA printers can produce high-quality, durable parts that are perfect for prototyping and functional testing.

Here are some of the benefits of using FacFox’s SLA 3D printing services for home appliances:

- High resolution and accuracy: SLA printing produces parts with a high degree of resolution and accuracy, which is essential for creating functional prototypes.

- Wide range of materials: FacFox offers a wide range of SLA resins to choose from, so you can find the perfect material for your needs.

- Fast turnaround times: We can print your parts quickly and efficiently, so you can get started on testing your prototypes sooner.

- Expert support: Our team of experts is here to help you every step of the way, from design to production.

Ready to Get Started?

If you are interested in using SLA 3D printing to create prototypes for your home appliance ideas, contact FacFox today. We will be happy to discuss your project and help you choose the right SLA printing service for your needs.

With our wide range of services, we can help you bring any home appliance idea to life.

Let FacFox help you turn your dream kitchen appliance into a reality!

Solution

- Step 1: 3D Model Design: A 3D model of the multi-function cooking machine was first designed using Solidworks software. This model included the base, control panel, digital display, square pots with rounded corners, and the stirring mechanism for the right pot.

- Step 2: 3D Printing Preparation: The 3D model was then uploaded to an SLA 3D printer and sliced into thin layers. The appropriate SLA Generic Resin for the desired properties (likely a high-resolution and heat-resistant resin) was loaded into the printer’s vat.

- Step 3: SLA Printing Process: A laser beam traced each layer of the 3D model onto the surface of the liquid resin, solidifying it into a solid plastic layer. This process was repeated layer by layer until the entire machine prototype was complete.

- Step 4: Post-Processing: Once printing was finished, the prototype was removed from the build platform and cleaned of any excess resin. Support structures, which may have been necessary for some parts during printing, were then carefully removed.

- Step 5: Finishing and Assembly: The individual parts of the prototype were then polished to achieve a smooth surface finish. Since the touch buttons were non-functional stickers, they were likely applied at this stage. Finally, all the parts were assembled together to create the final prototype.