Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

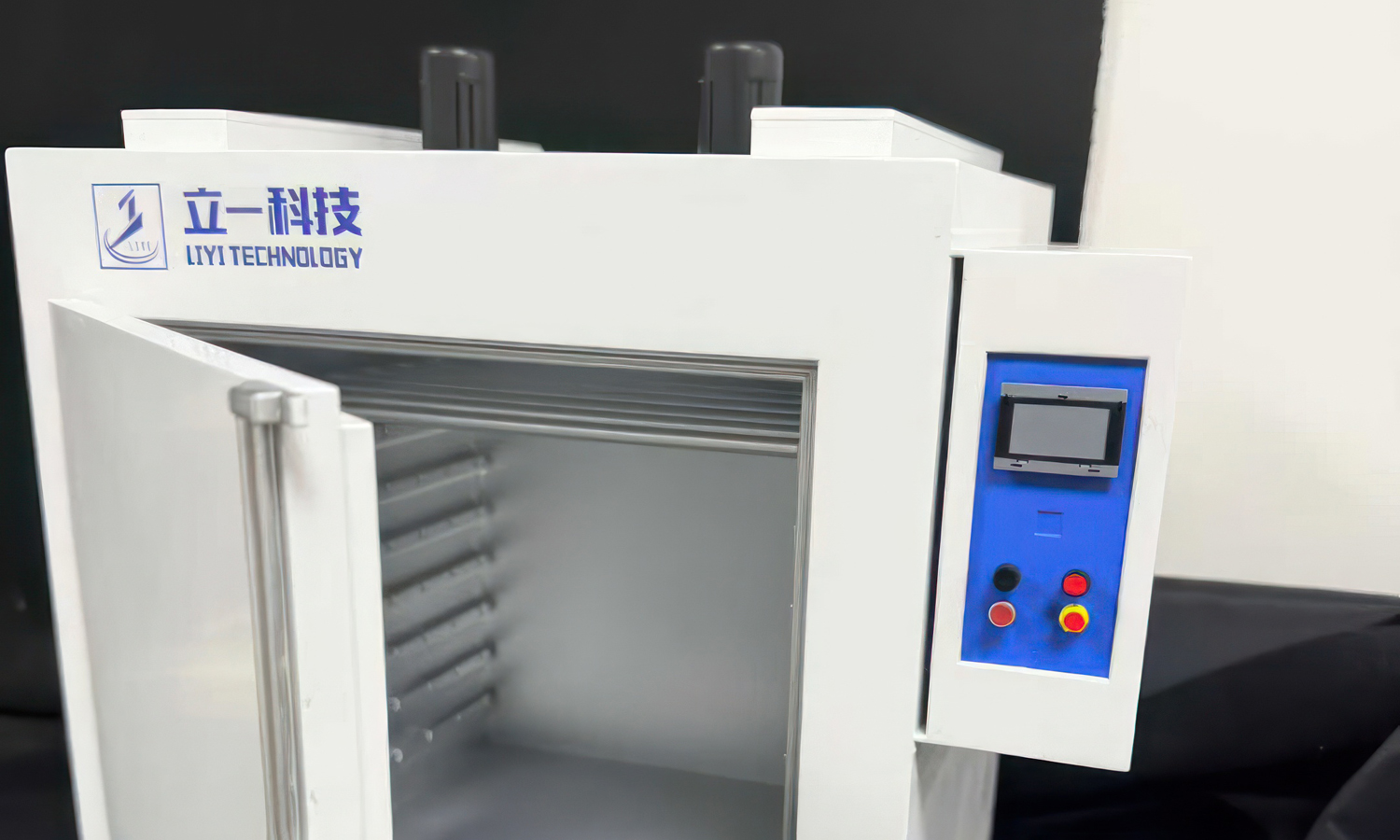

Visualizing industrial machinery requires more than just a 2D render; it requires a physical presence. This stunning appearance prototype from Liyi Technology showcases the future design language of their High-Temperature Precision Industrial Oven line.

Design Meets Functionality

Even as a non-functional model intended for aesthetic and ergonomic testing, the prototype captures the essential “pro-lab” feel:

- Industrial Aesthetics: The clean, white powder-coat finish combined with the signature Liyi blue control interface creates a look of reliability and precision.

- Ergonomic Layout: The side-mounted control box and heavy-duty vertical latch are positioned for maximum ease of use, allowing engineers to evaluate the human-machine interface (HMI) before moving into full-scale production.

- True-to-Life Details: From the top-mounted ventilation housings to the internal shelf rails, every detail has been scaled to provide a realistic sense of volume and footprint.

This prototype serves as a vital bridge between the digital design phase and the manufacturing floor, allowing stakeholders to touch, feel, and refine the equipment’s form factor.

Transform Your Concepts into Reality with FacFox

Bringing a complex industrial design from a screen to the physical world requires a manufacturing partner who understands precision. FacFox is your go-to provider for high-fidelity 3D printing and rapid prototyping services. Using advanced technologies like SLA for smooth surface finishes and SLS for durable structural components, FacFox can produce highly detailed appearance models that look and feel like the finished product. Whether you are building a scaled-down machine prototype or a full-size ergonomic mock-up, FacFox ensures your designs are presented with professional-grade quality.

Solution

-

Step 1: The digital 3D CAD model was optimized for physical output and was partitioned into modular components to ensure clean surface transitions.

-

Step 2: The main body and internal structures were fabricated using high-precision SLA 3D printing to achieve a smooth, industrial-grade finish.

-

Step 3: Each component was meticulously sanded and was primed to eliminate layer lines and prepare the surfaces for high-gloss coating.

-

Step 4: Professional automotive-grade paint was applied in the signature Liyi Technology color palette, and the logo was precision-printed onto the chassis.

-

Step 5: The control interface, including the screen and tactile buttons, was assembled and was integrated into the side-mounted panel.

-

Step 6: The final assembly was inspected for structural alignment and was polished to meet exhibition-quality standards.