- DMLS 3D Printed Titanium Alloy Calabash Miniatures

- PolyJet 3D Printed Girl Friends Full-color Miniature Memory Gift

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 15 workdays

Gallery

About Project

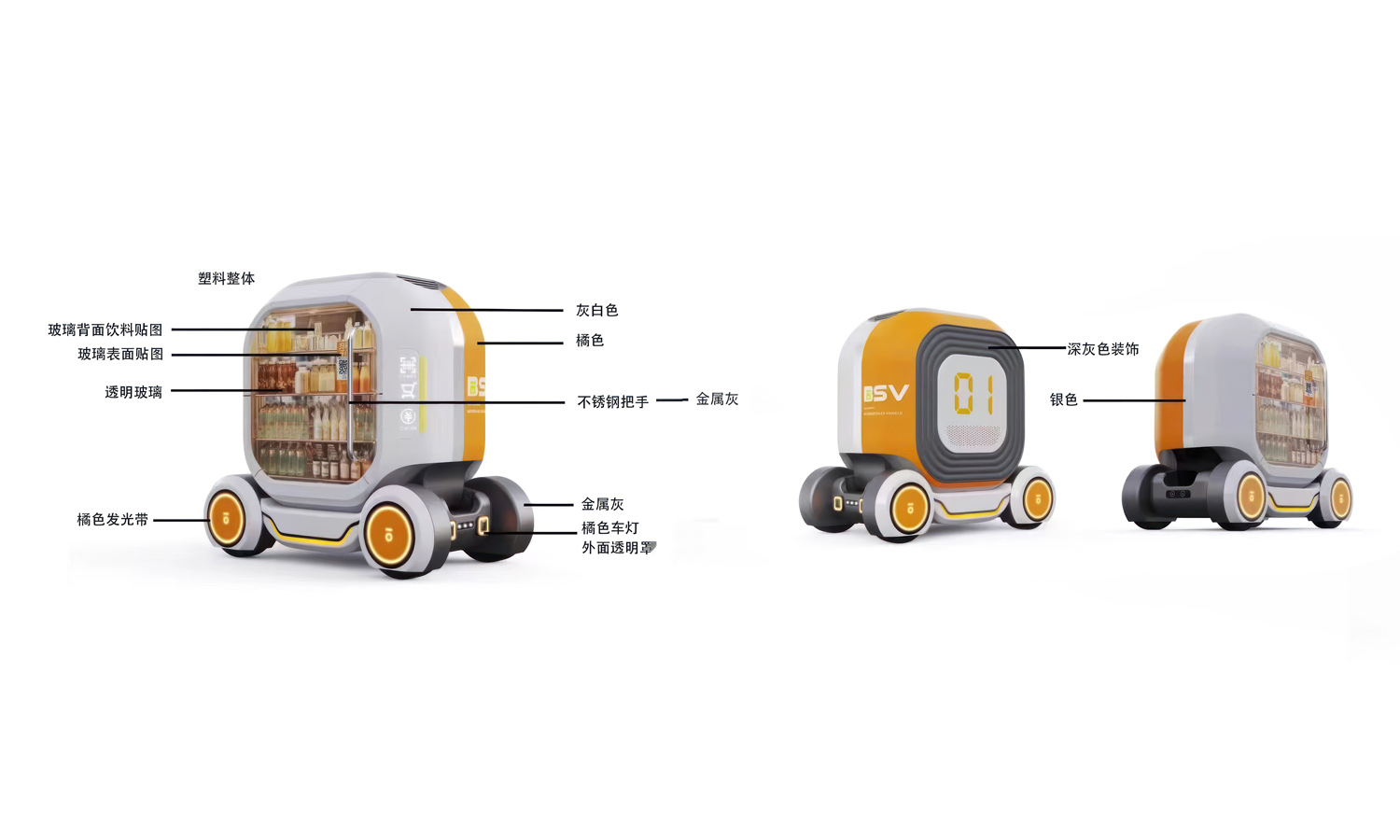

Introducing our groundbreaking SLA 3D printed movable unmanned vending machine prototype! Designed for unparalleled convenience, this innovative machine is set to redefine the retail landscape.

Key Features:

- Portable Design: Mounted on a wheeled skid base for effortless mobility.

- Refrigerated Storage: Maintains product freshness with a transparent refrigerated box.

- Contactless Shopping: Scan the QR code for easy access and purchases.

- Self-Sufficient Power: The base charges the refrigeration unit, ensuring uninterrupted operation.

From Concept to Reality with FacFox

This fully functional prototype was meticulously crafted using FacFox’s advanced SLA 3D printing services. By breaking down the complex design into multiple printable parts, we achieved exceptional detail and precision. The final product boasts a strikingly realistic appearance, thanks to expert painting and silk-screening techniques.

Your Vision, Our Expertise

FacFox is committed to turning innovative ideas into tangible products. Whether you’re developing a revolutionary vending machine or any other complex machinery, our 3D printing solutions provide the perfect foundation.

Ready to bring your concept to life? Contact FacFox today to explore how our SLA 3D printing services can help you transform your ideas into reality.

Solution

- Step 1: Design Creation. The design of the vending machine was created, consisting of a transparent refrigerated box mounted on a skid base with wheels for easy mobility.

- Step 2: 3D Modeling. The 3D model of the vending machine was developed, including the box, QR code area, and base.

- Step 3: Slicing. The 3D model was sliced into multiple pieces to fit the build volume of the SLA 3D printer.

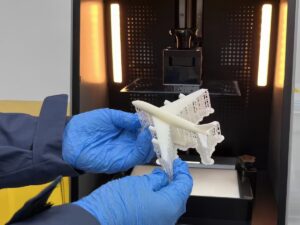

- Step 4:┬Ā Printing. The box and base were printed separately using SLA 3D printing technology. Each component was fabricated layer by layer.

- Step 5: Post-Processing. The printed pieces were cleaned and cured to ensure they were fully hardened and free of any residual resin.

- Step 6: Painting. The individual pieces were painted to match the design specifications. The transparent box was given a clear finish, while the base and other components were painted in the desired colors.

- Step 7: Shelf Creation. Shelves were printed on paper and were stuck inside the box to simulate real shelves.

- Step 8: Silk-Screening. Icons and labels were added to the surfaces using silk-screening techniques to enhance the visual appeal and functionality.

- Step 9: Sticker Application. Stickers indicating the use method of the machine were attached to the appropriate surfaces.

- Step 10: Assembly. The painted and finished pieces were assembled to form the complete vending machine prototype. The box was mounted on the skid base.

- Step 11: Final Touches. The prototype was inspected for any imperfections and final adjustments were made to ensure it closely resembled the rendering.