Material Resin, Rubber

Quantity 15 pcs

Price Range $1-100

Lead Time 4 workdays

Gallery

About Project

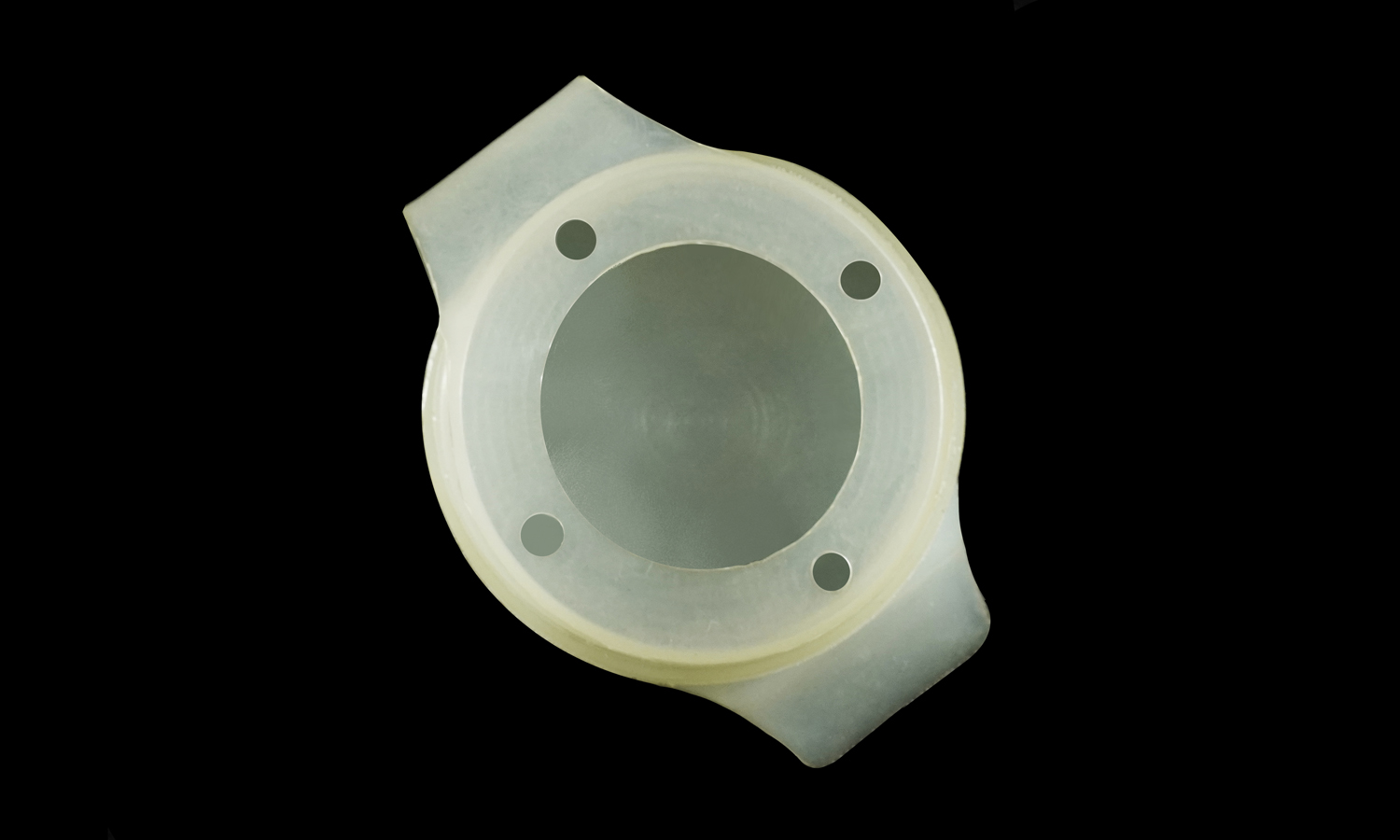

In prototype engineering, flexibility and dimensional accuracy are key to verifying mechanical fit before committing to mass production. This transparent polyurethane part was developed as a flexible coupling housing, connecting two rigid components while allowing slight movement and vibration absorption.

Function and Design

The design features two circular interfaces connected by a flexible waist.

- One end includes a smooth, shallow cavity that mates with a curved part.

- The opposite end features a ring with four mounting holes, enabling precise fastening.

- The translucent body provides visual access during assembly alignment, useful in optical or sensor modules.

The geometry ensures torsional flexibility and vibration damping while maintaining structural integrity – ideal for testing mechanical alignment and material behavior in a real environment.

Why PU Casting?

Polyurethane casting enables rapid, low-volume production of parts with rubber-like elasticity and optical clarity – perfect for mechanical tests, ergonomic studies, and pre-production validation.Compared with direct 3D printing, PU casting yields stronger, smoother, and more consistent results suitable for handling and assembly tests.

FacFox’s PU casting service delivers high-quality flexible parts for mechanical and optical assemblies, vibration-isolating housings, and aesthetic prototypes. Whether you need soft elastomers or rigid resins, our vacuum casting technology ensures precision and consistency from the first sample to short-run production.

Solution

- Step 1: The master model was 3D printed using SLA technology for high detail.

- Step 2: The printed pattern was post-cured and polished to ensure smooth replication.

- Step 3: A silicone mold was created around the master.

- Step 4: Degassed polyurethane resin was poured into the mold.

- Step 5: The mold was vacuum-treated to remove trapped air.

- Step 6: The part was cured at a controlled temperature.

- Step 7: Once solidified, it was demolded and lightly trimmed.

- Step 8: Final inspection confirmed flexibility, hole accuracy, and surface clarity.