- FDM 3D Printed Black PETG Monument Prototype

- SLA 3D Printed Clear Resin Praying Hands with a Cross Pendant

Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

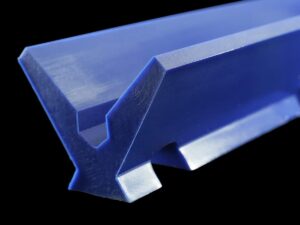

The FDM 3D printed white PLA Flange is a circular part that connects two pipes or tubes, usually made of white poly (lactic acid) (PLA) material, using the fused deposition modeling (FDM) 3D printing process. FDM is one of the most common and cost-efficient methods for 3D printing, which works by melting a string of plastic and applying it layer-by-layer onto a build platform. PLA is the most popular 3D printing material, which is bio-based, biodegradable, and easy to use. A cylinder flange can have various dimensions and specifications, depending on the application and design.

It has a good surface effect, which means it has a smooth and uniform appearance. The surface quality of FDM 3D printed parts depends on several factors, such as the nozzle size, layer height, print speed, infill density, and cooling settings. By adjusting these parameters, you can achieve different levels of surface finish and accuracy for your flange.

Another advantage of FDM 3D printed white PLA cylinder flange is that the holes are directly printed, which means you do not need to drill them manually. The holes are essential for attaching the flange to the pipe or tube with bolts and gaskets. By using a precise and reliable 3D printer, you can print accurate and consistent holes for your flange. However, if you want to improve the hole quality further, you can also use a drill to remove any excess material or burrs from the hole edges.

If you are interested in 3D printing your own flanges, you can try FacFoxŌĆÖs 3D printing service. FacFox is an online platform that offers various manufacturing solutions, including plastic and metal 3D printing, CNC machining, injection molding, sheet fabrication, and more. You can upload your 3D model, get an instant quote and printability check, choose from over 50 different industrial-grade materials, and receive your parts in as fast as 1-2 days. Visit their website facfox.com to learn more and start your project today!

Solution

- Step 1: A 3D model of the cylinder flange was created using computer-aided design (CAD) software. The model specified the dimensions, shape, and hole positions of the flange.

- Step 2: The 3D model was uploaded to a slicing software, which converted it into a series of instructions for the FDM 3D printer. The slicing software also determined the optimal print settings, such as the nozzle temperature, layer height, print speed, infill density, and support structures.

- Step 3: A spool of white PLA filament was loaded into the FDM 3D printer. PLA is a thermoplastic polymer that is bio-based, biodegradable, and easy to use.

- Step 4: The FDM 3D printer heated up the nozzle to melt the PLA filament and extruded it through a thin nozzle. The nozzle moved along the X, Y, and Z axes according to the instructions from the slicing software and deposited the melted material layer by layer on a build platform.

- Step 5: The 3D printer printed the cylinder flange from bottom to top, filling each layer with multiple passes of material. The printer also printed support structures to hold up any overhanging parts of the flange.

- Step 6: The 3D printer cooled down the nozzle and the build platform after completing the print. The printed cylinder flange was removed from the build platform and detached from the support structures. It was sanded to remove the marks.