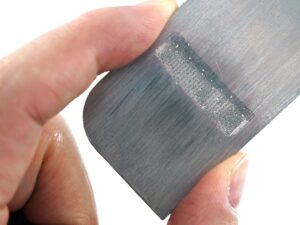

- Compression Molded Yellow Polyurethane Strip with Holes

- Binder Jet 3D Printed SS316L Schwarz Diamond Surface with Raw Finishing

Material Other

Quantity 60 pcs

Price Range $100-1,000

Lead Time 6 workdays

Gallery

About Project

One of our customers needed a thick PU disc with a hole in the middle to fit into their machine. The disc had to be strong and durable, as it was exposed to high stress and friction.┬ĀPU is a versatile material that can be molded into various shapes and sizes by compression molding.

Compression molding involves pouring liquid PU into an open mold and applying heat and pressure to cure the material. We have extensive experience in designing and manufacturing custom molded PU parts for various industries. We have in-house mold making and compression molding capabilities to produce PU parts according to the customer’s specifications. We also use high-performance PU systems and additives to ensure the quality and performance of the PU parts.

We made the PU discs by compression molding according to the customer’s requirements.┬ĀThe customer was very satisfied with the products.┬ĀWe are proud of our work and our products. FacFox is a leading provider of custom molded PU parts for various applications. We have techniques like compression molding, spin casting, open casting, vacuum casting, and low pressure injection molding. We can handle any project from concept to delivery, with quality assurance and customer service as our top priorities. If you need custom PU parts for your project, contact us today and we will give you a quote.

Solution

- Step 1: A mold was designed and made according to the customer’s specifications.

- Step 2: Liquid PU was mixed with curatives and additives to form a PU coumpound.

- Step 3: The mold was preheated and coated with a release agent.

- Step 4: The PU coumpound was poured into the mold cavity and distributed evenly.

- Step 5: The mold was closed and placed in a compression press.

- Step 6: Heat and pressure were applied to the mold to cure the PU material.

- Step 7: The mold was opened and the PU disc was removed from the mold.

- Step 8: The PU disc was trimmed and inspected for quality.