Material Resin, Metal

Quantity 1 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

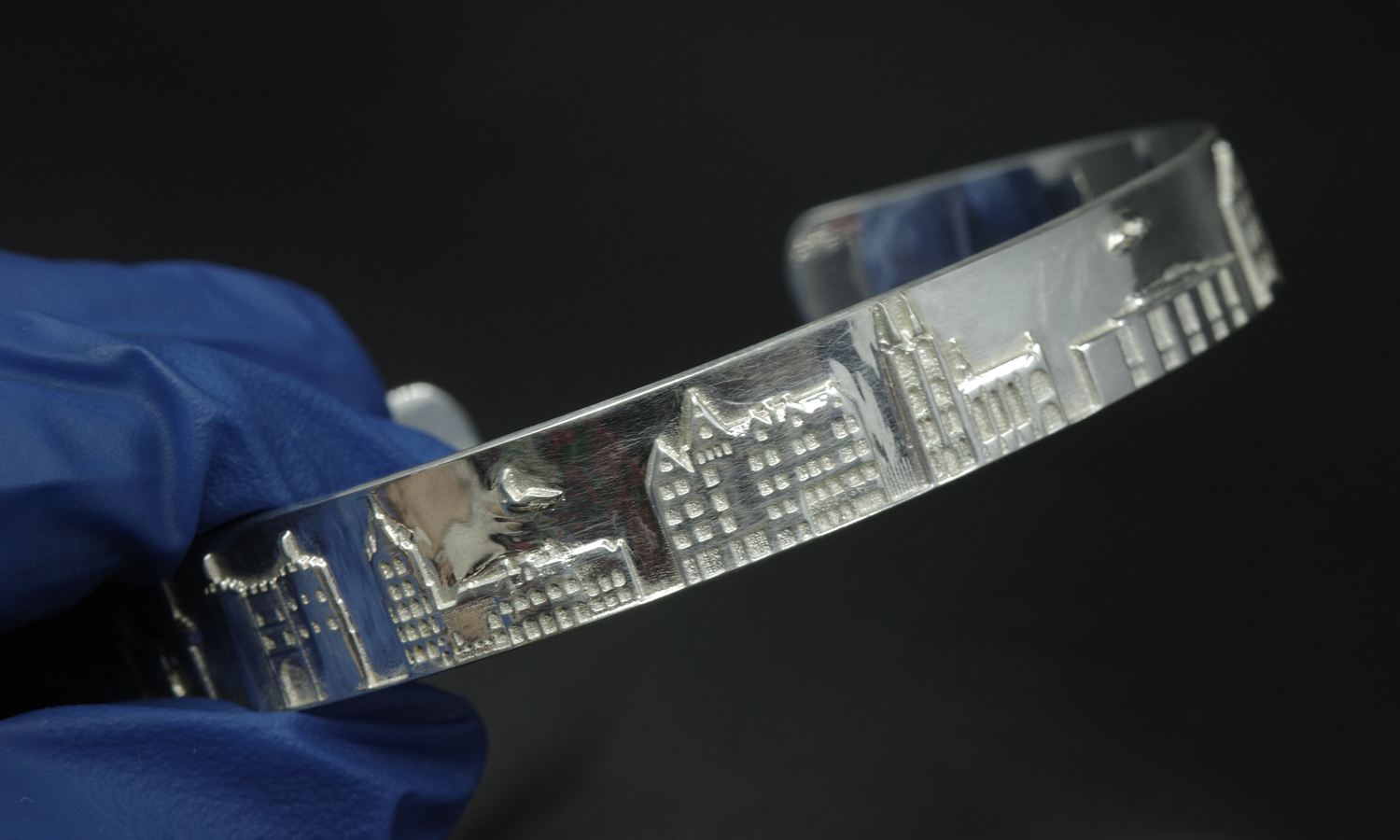

Imagine wearing a piece of a city on your wrist. These unique silver bracelets capture the architectural essence of German cityscapes, offering a tangible connection to place and memory. Each bracelet tells a story, featuring recognizable buildings and skylines rendered in intricate detail.

One bracelet, the larger of the two, showcases the grandeur of Cologne, likely featuring the iconic Cologne Cathedral (K├Člner Dom) with its soaring spires. The smaller bracelet represents M├╝nster, possibly depicting St. Lamberti Church with its distinctive Gothic spire. The designs capture the spirit of each city. The smaller bracelet also incorporates a bird/dove shape, which could be a stylized interpretation of peace or a local emblem.

But how are these miniature works of art created? The process begins with a 3D printed resin pattern. The intricate details of the cityscapes are first designed digitally, then brought to life using high-resolution 3D printing. This creates a highly accurate and detailed model of the bracelet.

This resin pattern then becomes the heart of the ancient lost-wax casting process. The resin model is encased in a mold, and the resin is melted away (“lost”), leaving a perfect cavity. Molten silver is poured into this cavity, taking on the exact shape of the original 3D printed pattern. Once cooled, the silver is carefully finished and polished, resulting in a beautiful and durable bracelet. This method allows for exceptional detail and captures the nuances of the architectural designs.

Looking to create your own custom jewelry, incorporating intricate designs and personalized touches? FacFox offers professional 3D printing and lost-wax casting services, perfect for bringing your unique visions to life. From initial design to the final cast piece, FacFox combines cutting-edge technology with traditional craftsmanship to deliver exceptional results.

Solution

- Step 1: The architectural designs for the bracelets were created digitally.

- Step 2: High-resolution resin patterns of the bracelets were produced using 3D printing technology, capturing all the intricate details of the cityscapes.

- Step 3: These 3D printed resin patterns were carefully prepared for investment casting.

- Step 4: The resin patterns were encased in an investment plaster (a type of refractory material), forming a rigid mold.

- Step 5: The mold was heated in a kiln, causing the resin patterns to melt and evaporate, leaving a hollow cavity that perfectly matched the original designs. This is where the term “lost-wax” (or “lost-resin” in this case) casting originates.

- Step 6: Molten silver was poured into the heated mold cavity.

- Step 7: After the silver had solidified and cooled, the investment plaster mold material was broken away, revealing the rough silver castings of the bracelets.

- Step 8: Excess material and sprues were carefully removed from the cast silver bracelets.

- Step 9: Both the initial 3D printed resin patterns and the final cast silver parts were polished by hand with fine-grit sandpaper. However, due to the intricate and sometimes recessed structures of the architectural patterns, some parts were difficult to reach and remained somewhat rough, preserving a unique tactile quality.

- Step 10: The bracelets underwent a final cleaning and finishing process, preparing them for wear.