Material Resin, Metal

Quantity 14 pcs

Price Range $1-100

Lead Time 8 workdays

Gallery

About Project

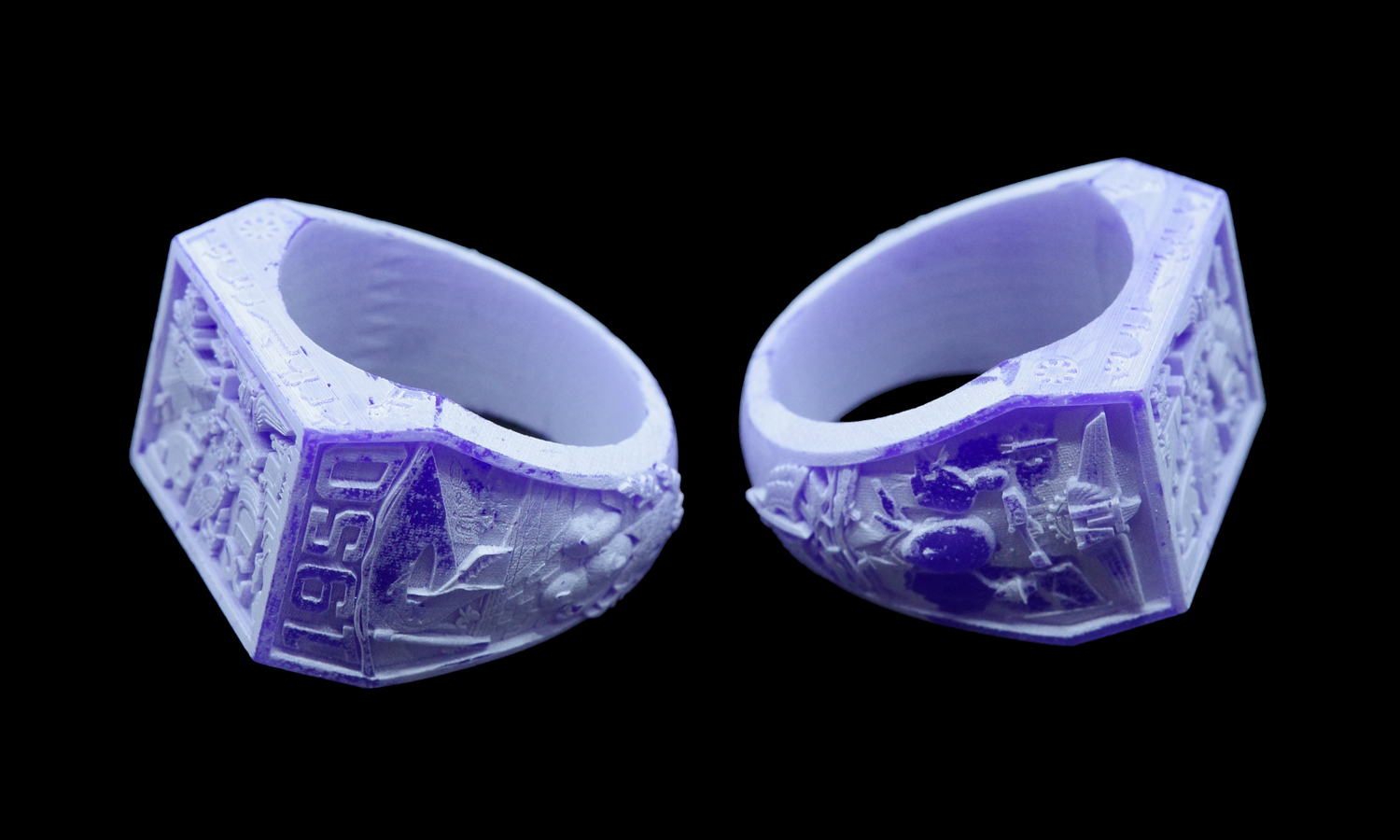

These custom silver rings demonstrate the capabilities-and the limitations-of combining high-resolution 3D printing with traditional casting methods. Each ring began as a detailed 3D model, designed to capture complex imagery, including miniature landscapes, fine text, and symbolic motifs.

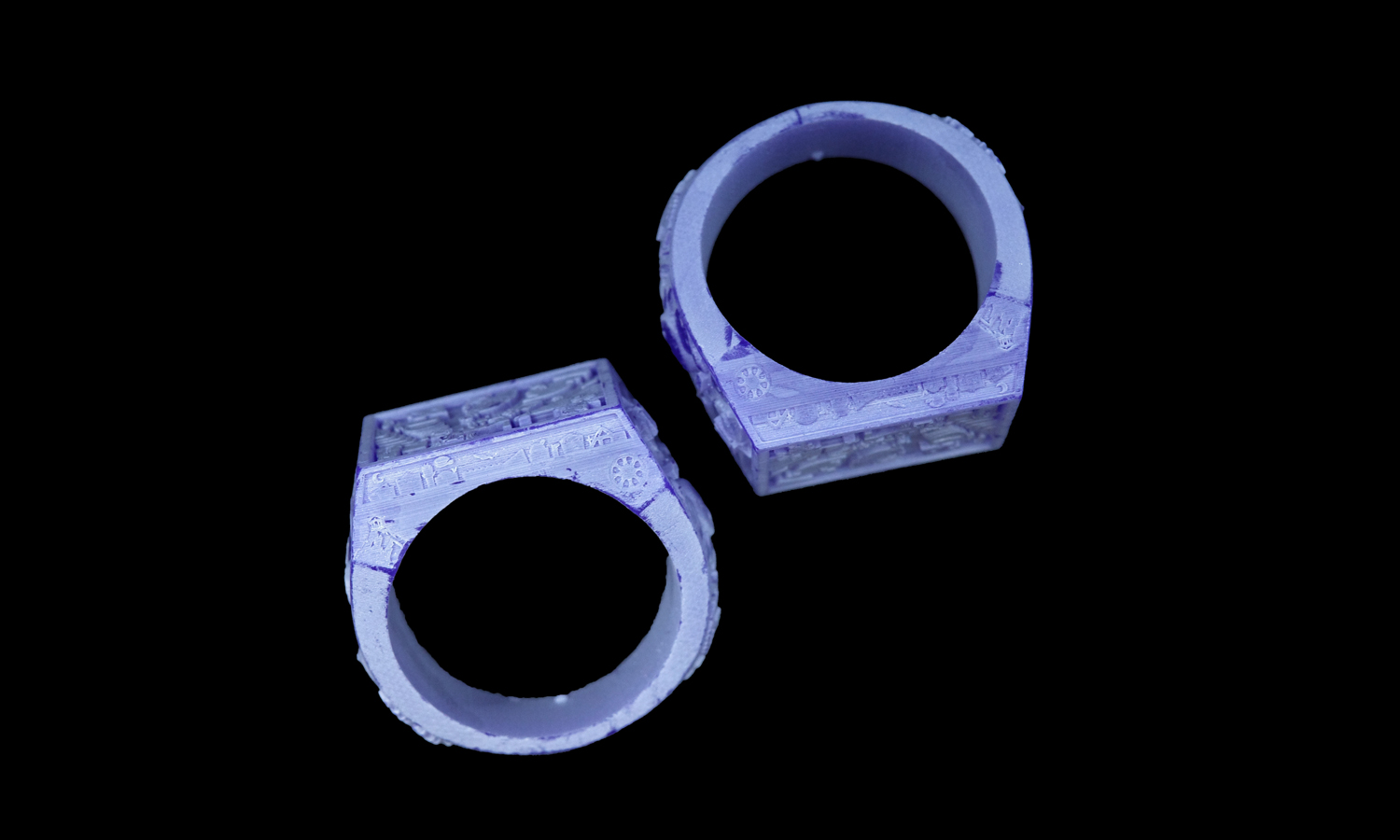

The patterns were printed using a castable resin specifically developed for investment casting. The 3D prints successfully reproduced most of the design features, offering crisp details and accurate proportions. Fine surface textures, raised patterns, and even small inscriptions were clearly visible on the printed patterns. Some extremely fine or shallow elements were naturally more delicate and required careful handling during post-print processing.

The casting was done using a traditional lost resin process. After burnout, molten silver was poured into the prepared molds. Overall, the casting process preserved the essential features of the original design, transferring most of the printed details into the metal. However, some minor surface imperfections are visible, such as light porosity and slight softening of sharp edges-common outcomes in small-scale metal casting, especially when working with intricate patterns.

The raw castings exhibit a matte, unfinished surface typical of unpolished silver. The details are present but would benefit from additional post-processing to bring out their full sharpness. Polishing, light filing, and possibly some selective hand engraving will further refine the design and enhance visual clarity.

While not flawless, the results accurately reflect the current state of small-scale jewelry production using 3D printed patterns. The process successfully bridges the gap between digital design and handcrafted finishing, allowing for complex custom designs that would be difficult or impossible to create using only traditional techniques.

With proper finishing, these castings will transform into unique, high-quality custom rings, showcasing both modern technology and skilled craftsmanship.

At FacFox, we combine advanced 3D printing technology with traditional metal casting to help designers, jewelers, and manufacturers bring their ideas to life. Whether you’re creating intricate jewelry, custom hardware, or small-batch prototypes, our team ensures high-precision printing, reliable casting, and expert post-processing to achieve the best possible results. From concept to finished product, FacFox offers a complete solution for your custom manufacturing needs.

Solution

- Step 1: The design files were created using 3D modeling software, where all intricate details such as text, symbols, and surface textures were carefully incorporated.

- Step 2: The digital models were prepared for printing and sent to a high-resolution 3D printer using castable resin. The patterns were printed with fine layer thickness to ensure maximum detail fidelity.

- Step 3: The printed resin patterns were inspected for defects, and any minor surface residues or supports were carefully removed by hand to maintain detail integrity.

- Step 4: The cleaned patterns were attached to wax sprues and mounted onto a casting tree, which was then placed inside a metal flask for investment casting preparation.

- Step 5: A liquid investment material was poured into the flask, fully encasing the printed patterns. The investment was allowed to cure and harden, forming a negative mold around the patterns.

- Step 6: The flask was placed in a burnout furnace where the resin patterns were vaporized and removed, leaving behind a detailed cavity corresponding to the original design.

- Step 7: Molten silver was heated and poured into the empty mold cavities under controlled conditions to ensure complete metal flow and fill.

- Step 8: Once cooled, the investment molds were broken away, and the raw cast rings were retrieved.

- Step 9: The castings were cut from the sprues, and the initial surface cleaning was performed to remove any remaining investment material and oxidation.

- Step 10: The raw silver rings were inspected for casting defects such as porosity or incomplete fills. Minor surface imperfections were noted for correction during finishing.

- Step 11: The rings underwent preliminary sanding and polishing to smooth the surfaces and begin revealing the fine details.

- Step 12: Additional hand finishing, filing, and polishing were performed as needed to refine the sharpness of the details and achieve the desired surface quality for final presentation.