- SLA 3D Printed Grid-like Complex Frameworks Resin Architectural Sculpture

- SLA 3D Printed Resin Colorful Venting System Demonstration Model

Gallery

About Project

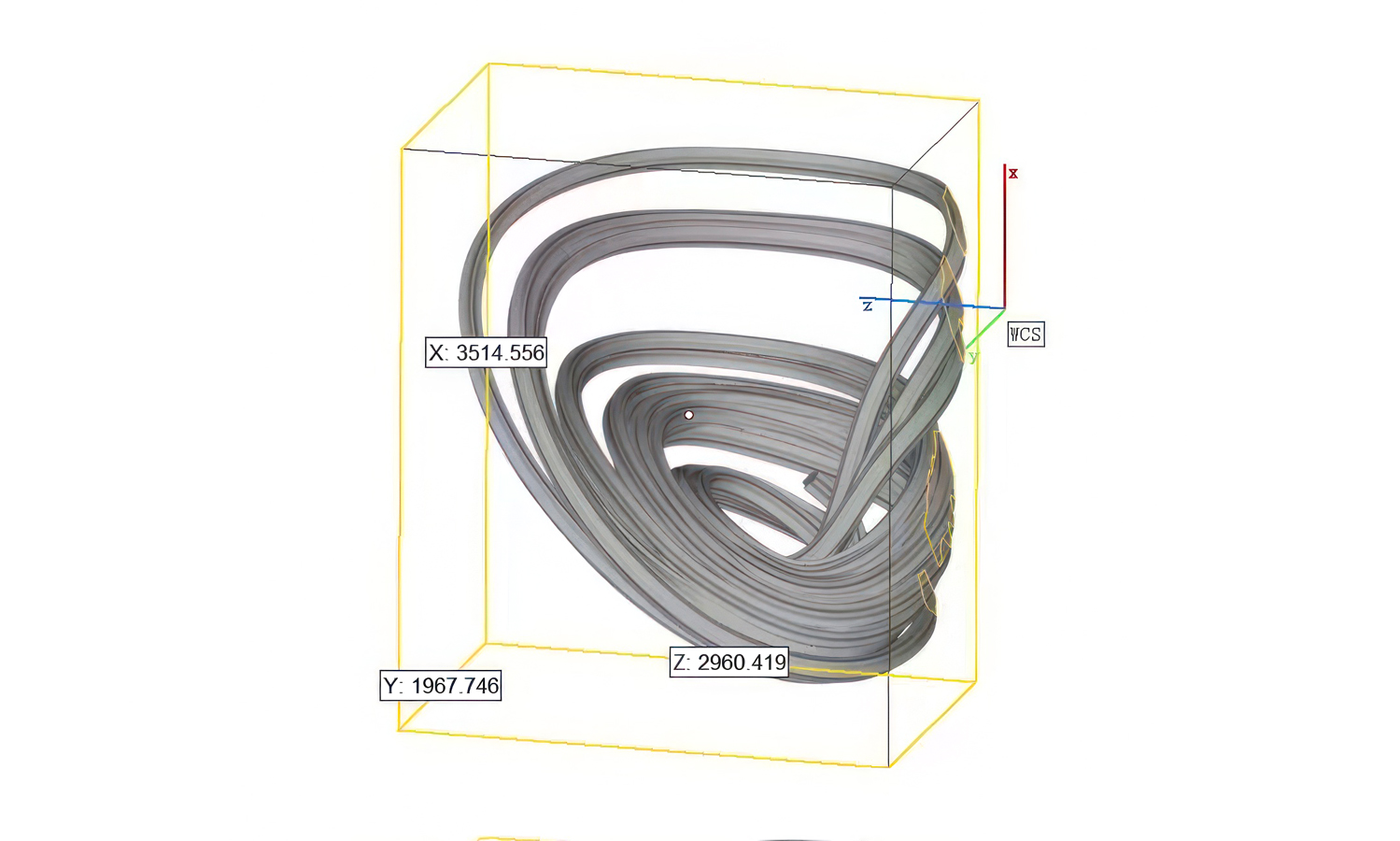

In the realm of contemporary art, 3D printing has emerged as a powerful tool for realizing intricate and ambitious designs. Among these, the large-format swirling vortex sculpture stands out as a testament to the technology’s potential. This awe-inspiring structure, composed of multiple loops and curves that intertwine, resembles a series of concentric circles or spirals, creating an intricate and fluid form that evokes the image of a swirling vortex.

The Art of 3D Printing

The swirling vortex sculpture is a remarkable example of how 3D printing can be used to create large-scale, complex objects. The sculpture is split into multiple parts, each of which is 3D printed separately before being assembled and fixed. This approach allows for greater precision and control over the printing process, resulting in a finished product that is both visually stunning and structurally sound.

FacFox: Your Partner for Large-format 3D Printing

FacFox is a leading provider of 3D printing services for large-format sculptures. Our team of experts has the experience and knowledge to help you bring your vision to life. We offer a variety of 3D printing technologies, including FDM, SLA, SLS, and DLP, so you can choose the best option for your project.

Contact Us

If you are interested in creating a large-format 3D-printed sculpture, please contact FacFox today. We would be happy to discuss your project and provide you with a quote.

Additional Information

- FacFox also offers a variety of other 3D printing services, including rapid prototyping, CNC machining, and vacuum casting.

- Our team of experts can help you with every stage of your project, from design to production.

- We offer competitive pricing and fast turnaround times.

- We are committed to providing our customers with the highest level of quality and customer service.

Solution

- Step 1: Design Creation.┬ĀThe design of the swirling vortex sculpture was created using 3D modeling software. The intricate loops and curves were carefully planned to achieve the desired fluid form.

- Step 2: Model Slicing.┬ĀThe 3D model was sliced into multiple parts to accommodate the large size of the sculpture. Each part was prepared for printing by generating the necessary G-code.

- Step 3: Material Selection. Filament material ABS was selected based on the desired properties of the final sculpture. The filament was loaded into the FDM 3D printer.

- Step 4: Printing Process.┬ĀEach part of the sculpture was printed layer by layer using the FDM (Fused Deposition Modeling) technique. The printer extruded the filament through a heated nozzle, depositing it onto the build platform.

- Step 5: Support Structures.┬ĀSupport structures were automatically generated and printed alongside the sculpture parts to ensure stability during the printing process. These supports were later removed.

- Step 6: Part Removal.┬ĀOnce printing was completed, the individual parts were carefully removed from the build platform. Any remaining support structures were detached.

- Step 7: Post-Processing.┬ĀThe printed parts were cleaned and any imperfections were smoothed out. This step involved sanding, filing, or using chemical treatments to achieve a polished surface.

- Step 8: Assembly.┬ĀThe individual parts of the sculpture were assembled. The parts were aligned and joined together using adhesive or mechanical fasteners to ensure a secure fit.

- Step 9: Finishing Touches. The assembled sculpture was given final touches, such as additional sanding or painting, to enhance its appearance and durability.

- Step 10: Installation.┬ĀThe completed sculpture was mounted on a base and installed in its intended location. The base provided stability and allowed the sculpture to stand upright.