- CNC Turned SS316L Rotary Turbo High-pressure Nozzle

- CNC Milled SS316L Coaxial Feedthrough Pin Prototype

Gallery

About Project

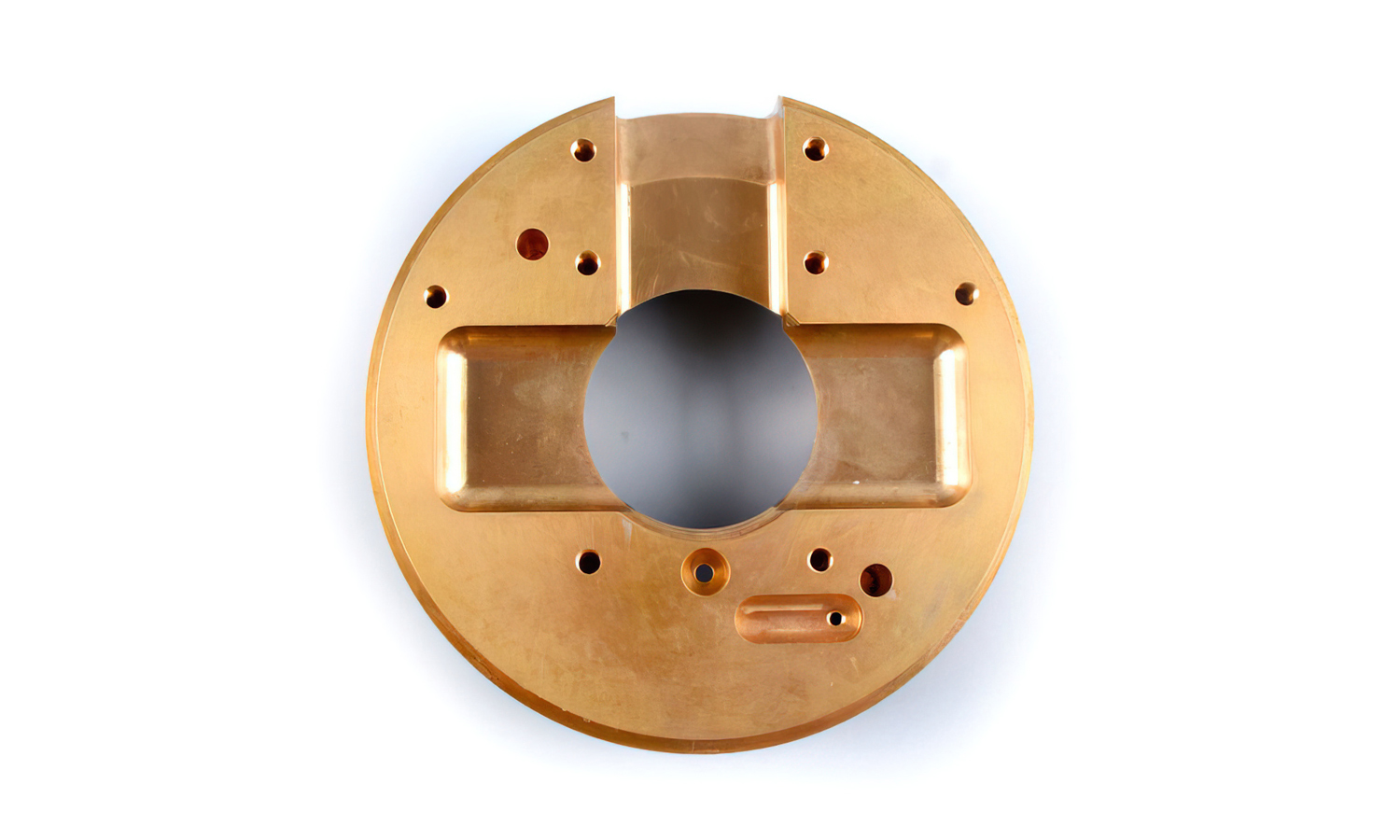

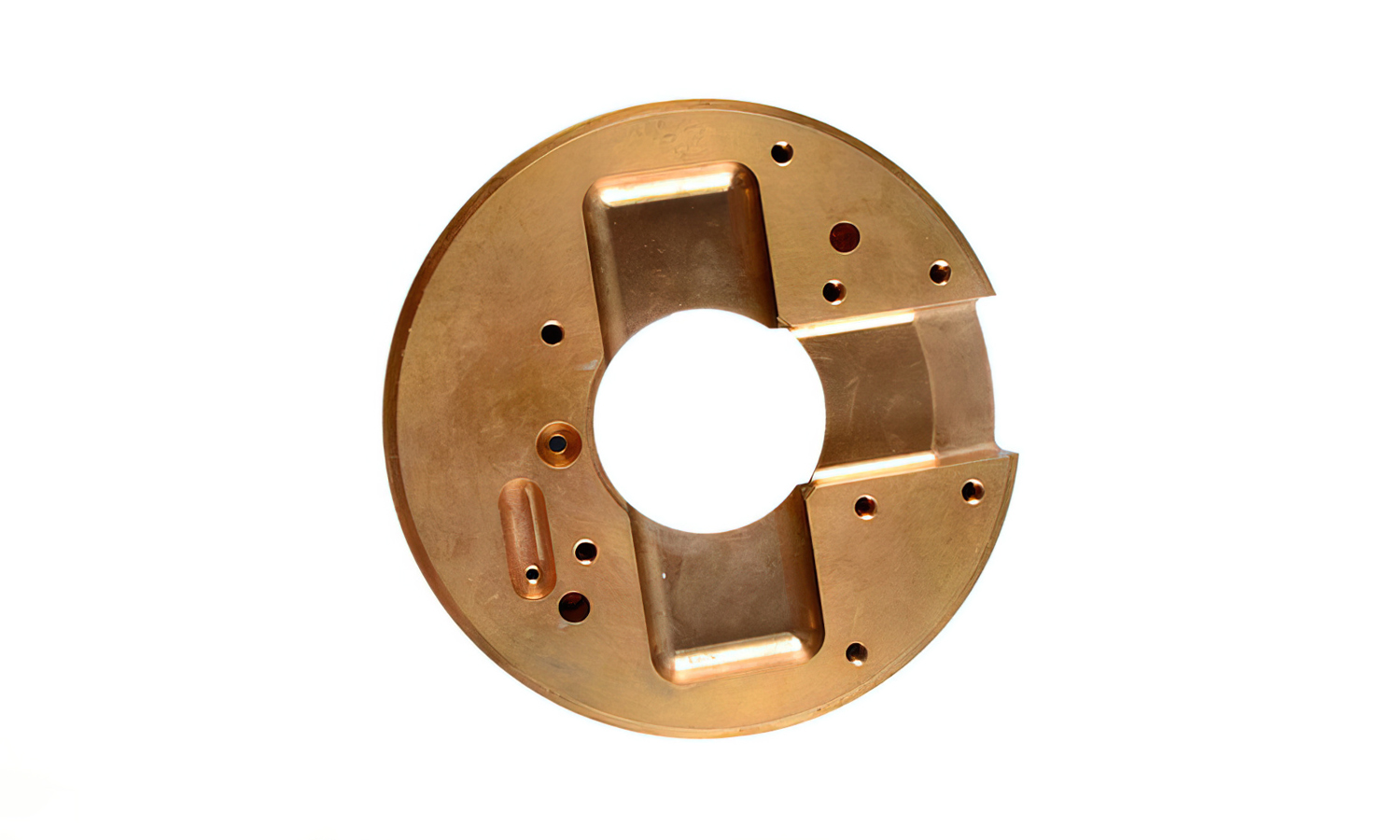

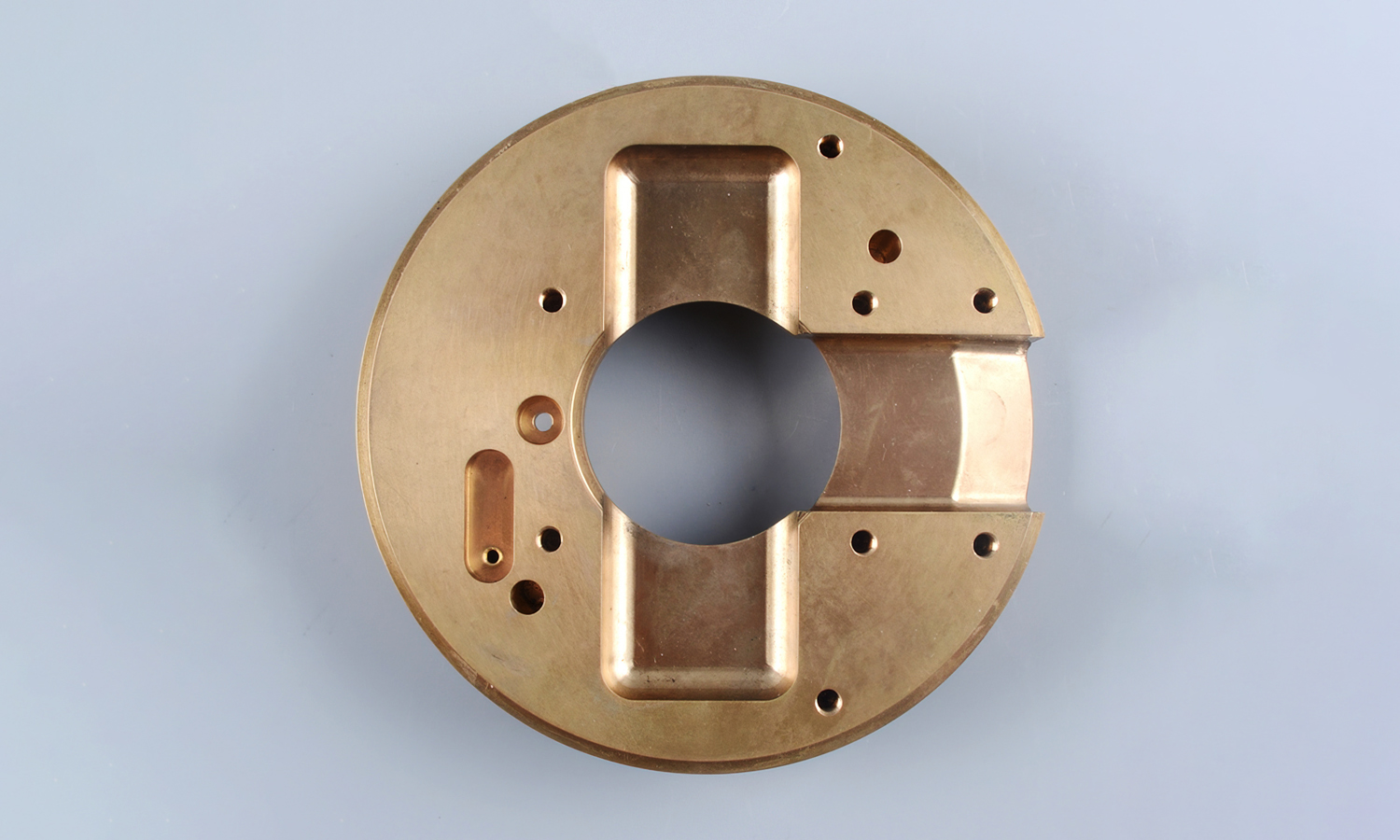

If you are looking for a high-quality gas burner ring for your stovetop, you might want to consider a CNC-milled brass gas burner ring from FacFox. FacFox is a leading provider of CNC turning and milling services for the domestic appliance industry, offering fast, reliable, and cost-effective solutions for your machining needs.

A gas burner ring is a circular device that allows gas to pass through and mix with air, creating a flame for cooking. The gas burner ring has a big round hole in the middle, which is connected to the gas supply. The ring also has a raised lip around the edge, which helps to keep pots and pans stable on the stovetop.

Gas burner rings are typically made of brass because it is a good conductor of heat. This means that the ring heats up quickly and evenly, which is important for cooking. Brass is also a durable material that can withstand the high temperatures of a stovetop. Brass has a golden color and a smooth surface, which adds to the aesthetic appeal of your kitchen.

One of the advantages of using a CNC-milled brass gas burner ring is that it can be customized to your specifications. CNC milling is a process that uses computer-controlled machines to remove material from a solid block of metal, creating complex shapes and features. CNC milling can create precise and consistent parts with high accuracy and efficiency.

FacFox uses advanced CNC milling machines that can handle various types of metals, including brass. FacFox can create gas burner rings with different diameters, thicknesses, and hole patterns, depending on your requirements. FacFox can also drill many small holes around the surface of the ring, which allow the gas to escape and create a uniform flame. Contact FacFox today and see what they can do for you.

Solution

- Step 1: A CAD model of the gas burner ring was designed using CAD software.

- Step 2: The CAD model was converted into a CNC program using CAM software. The CNC program contained the instructions for the CNC machine to perform the milling operations.

- Step 3: A brass block was clamped on the work table of the CNC milling machine. The brass block was the raw material for the gas burner ring.

- Step 4: The CNC milling machine was set up with the appropriate tools, such as end mills, drill bits, and face milling cutters. The tools were mounted on the spindle of the machine, which could rotate at different speeds and move along different axes.

- Step 5: The CNC milling machine executed the CNC program, which controlled the movement of the spindle and the tools. The tools removed material from the brass block, creating the shape and features of the gas burner ring.

- Step 6: The CNC milling machine drilled many small holes around the surface of the ring, which allowed the gas to escape and create a uniform flame.

- Step 7: The CNC milling machine finished the milling process and released the gas burner ring from the work table. The gas burner ring was then inspected and cleaned.