- CNC Machining Al6061 Compound Miter Saw Base Assembly Part

- Lost-resin Casting Silver Rings Cast from SLA 3D Printed Patterns

Gallery

About Project

Grill grate vent covers play a crucial role in various applications, from HVAC systems to drainage solutions. They provide essential airflow while preventing debris and unwanted objects from entering. When it comes to quality and durability, CNC machined SS304L grill grate vent covers stand out.

What does it look like?

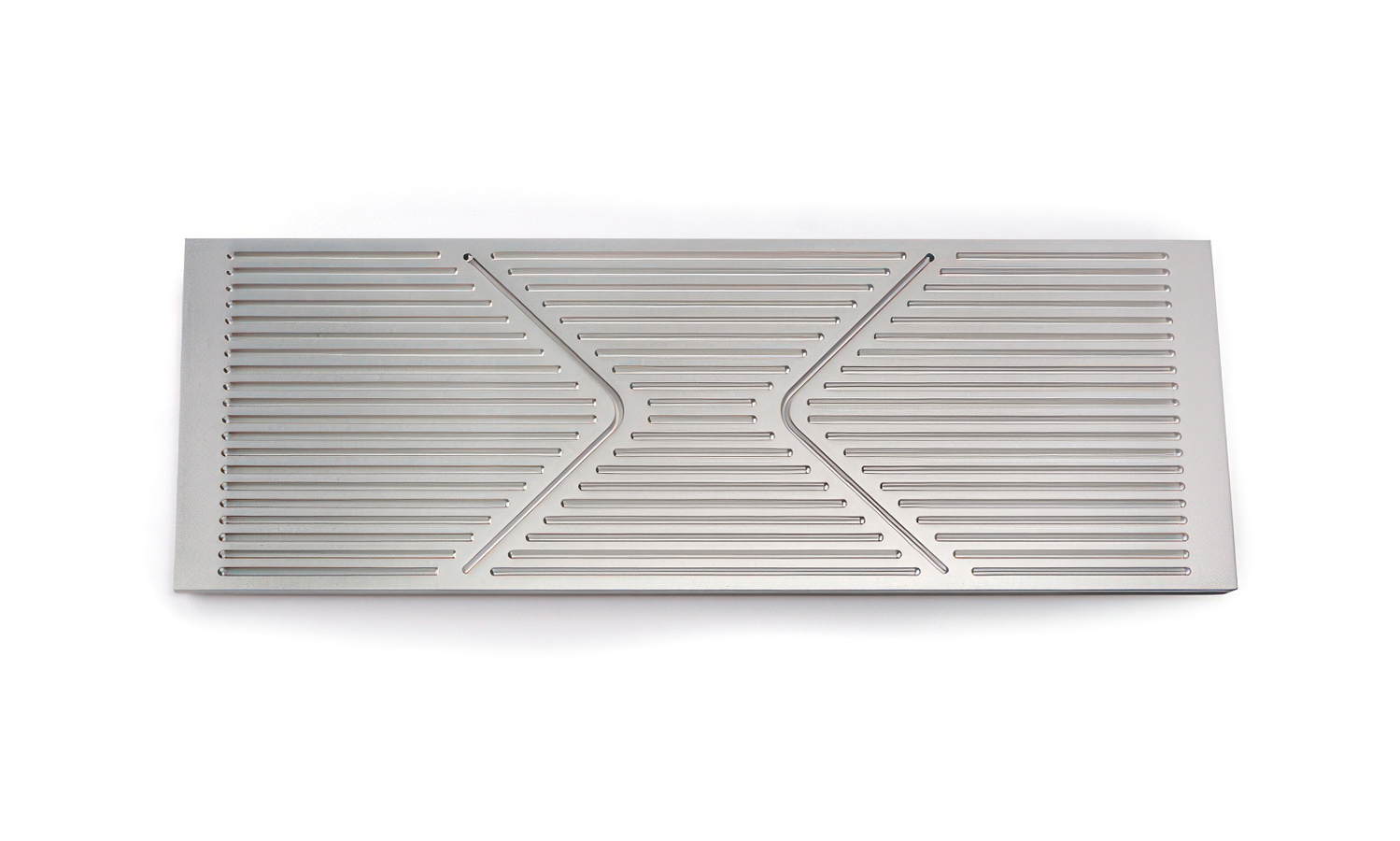

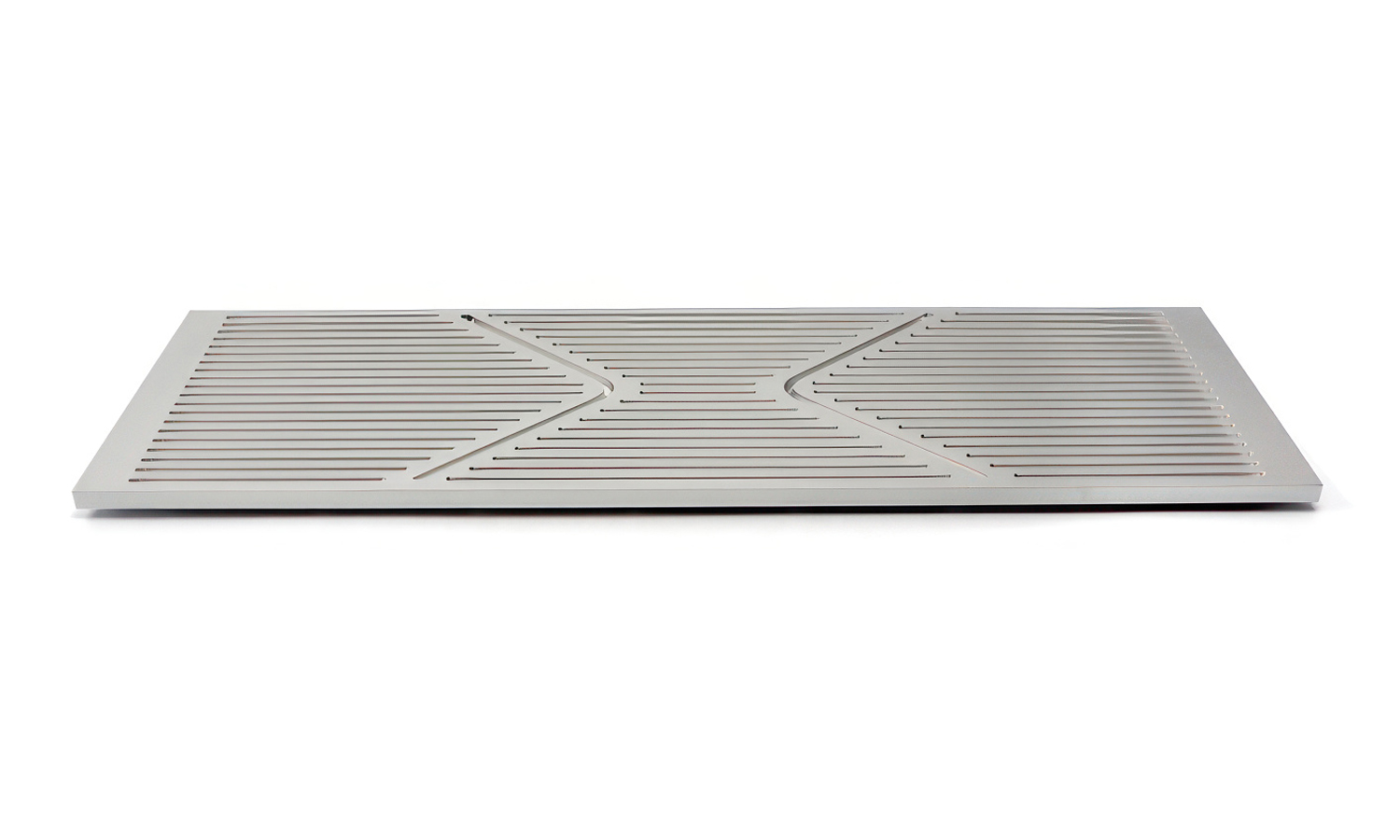

This type of vent cover, typically features a rectangular shape with a series of parallel slits or louvers. These slits allow for efficient airflow. Often, there’s a design element, such as an “X” or butterfly-like pattern created by intersecting diagonal lines of slits, adding both functionality and visual appeal. The image shows a sleek, metallic finish, indicative of the stainless steel material.

Why SS304L?

SS304L, a low-carbon version of 304 stainless steel, offers excellent corrosion resistance, making it ideal for environments where exposure to moisture or chemicals is a concern. Its strength and durability ensure a long lifespan for the vent cover.

The Precision of CNC Machining

CNC (Computer Numerical Control) machining allows for the creation of intricate designs with exceptional accuracy. This precision is crucial for ensuring proper airflow and a perfect fit. The process involves using computer-controlled machines to cut and shape the stainless steel, resulting in a high-quality, consistent product. The image highlights the precise cuts and perforations achieved through CNC machining.

Applications

These vent covers are versatile and find use in:

- HVAC systems

- Drainage systems

- Furniture design

- Architectural elements

Looking for a Custom Solution?

If you need a custom-designed grill grate vent cover, consider FacFox’s CNC machining service. They offer high-precision manufacturing and can work with SS304L to create vent covers that meet your specific requirements.

Solution

- Step 1: Design was finalized. The detailed CAD (Computer-Aided Design) model of the grill grate vent cover, including all dimensions, slot patterns, and any aesthetic features, was created and approved.

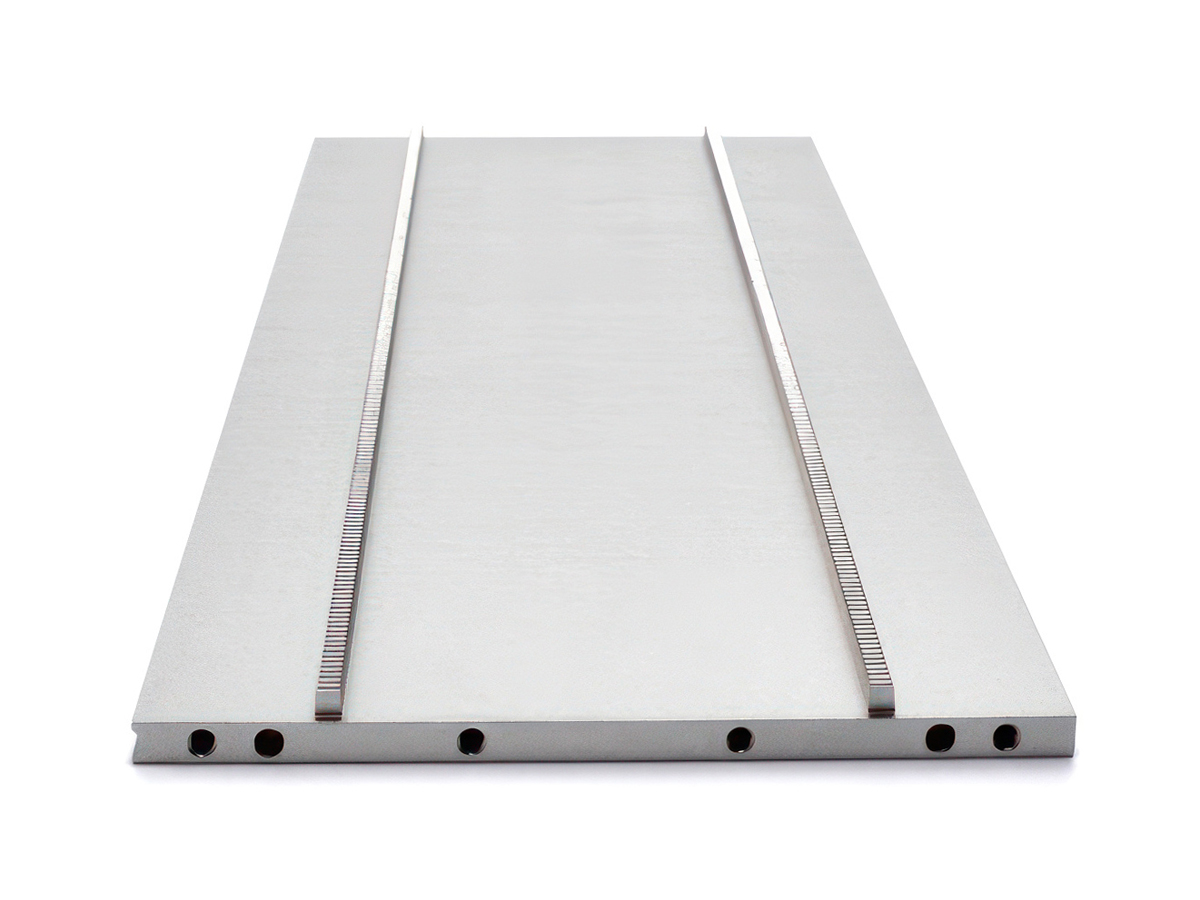

- Step 2: Material was selected and prepared. A sheet or billet of SS304L stainless steel, suitable for the dimensions of the vent cover, was sourced. It was then cut to the rough required size, if necessary, and secured onto the CNC machine’s workholding fixture.

- Step 3: Toolpaths were programmed. Based on the finalized CAD model, CAM (Computer-Aided Manufacturing) software was used to generate the specific toolpaths and instructions for the CNC machine. This included defining cutting speeds, feed rates, and tool changes for each machining operation.

- Step 4: Machining operations were performed. The SS304L material was loaded into the CNC machine. The programmed instructions were executed, and various tools, such as end mills and slotting cutters, were used to precisely cut, mill, and shape the material according to the design. This included creating the parallel slits, the central decorative pattern, and the outer perimeter of the vent cover.

- Step 5: Deburring and finishing were conducted. After machining, any burrs or sharp edges left by the cutting process were removed. This was typically done through processes like deburring, sanding, or tumbling to achieve a smooth and safe finish.

- Step 6: Surface treatment was applied (if required). Depending on the desired aesthetic and corrosion resistance, a surface treatment such as brushing, polishing, or passivating was applied to the SS304L vent cover.

- Step 7: Quality inspection was performed. The finished grill grate vent cover was thoroughly inspected to ensure it met all specified dimensions, tolerances, and surface finish requirements. This ensured the product’s functionality and aesthetic quality.

- Step 8: Packaging was completed. Once approved, the SS304L grill grate vent cover was carefully packaged to prevent damage during transit and prepared for shipment.