Ceramic 3D Printed Shades for Wall Lights & Sconce

Posted on 2020-02-06 in Furniture ┬Ę Õ«ČÕģĘ

Gallery

About Project

Ceramic is a traditional inorganic material with a history of thousands of years. It’s hard and brittle, make the process and shaping particularly difficult.

Traditional ceramic processing can only produce simple products with high costs and long production cycles. The development of ceramic 3D printing technology makes it possible to prepare complex ceramic products with fast speed and high precision.

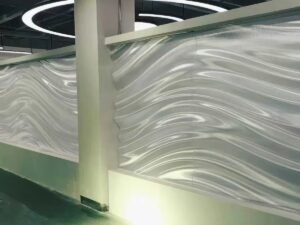

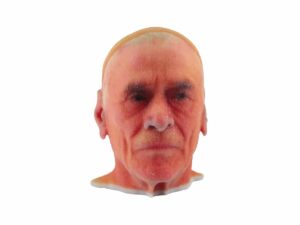

The sconce shades in the photos are one application of ceramic 3D printing. With exquisite patterns, novel geometric shapes, cold and smooth surfaces, the wall lights can be elegant decorations in your home.

Solution

- Step 1: According to our clients’ requirements, select appropriate raw materials, generally including ceramic powder, binder, and additives. Mix them evenly in a certain proportion.

- Step 2: Use Liquid Deposition Modeling technology to realize the forming of ceramic parts and obtain prints with specific shapes and structures.

- Step 3: The ceramic prints are cleaned, surface-enhanced, repaired, dried and processed with other post-treatments. This step intends to make the strength and precision of the body to meet the requirements, which is beneficial to the subsequent heat-treatment process.

- Step 4: Put the prints into the furnace, and conduct heat treatment with a properly set temperature system, firing atmosphere and pressure. After sintering and cooling, the final ceramic products can be obtained.