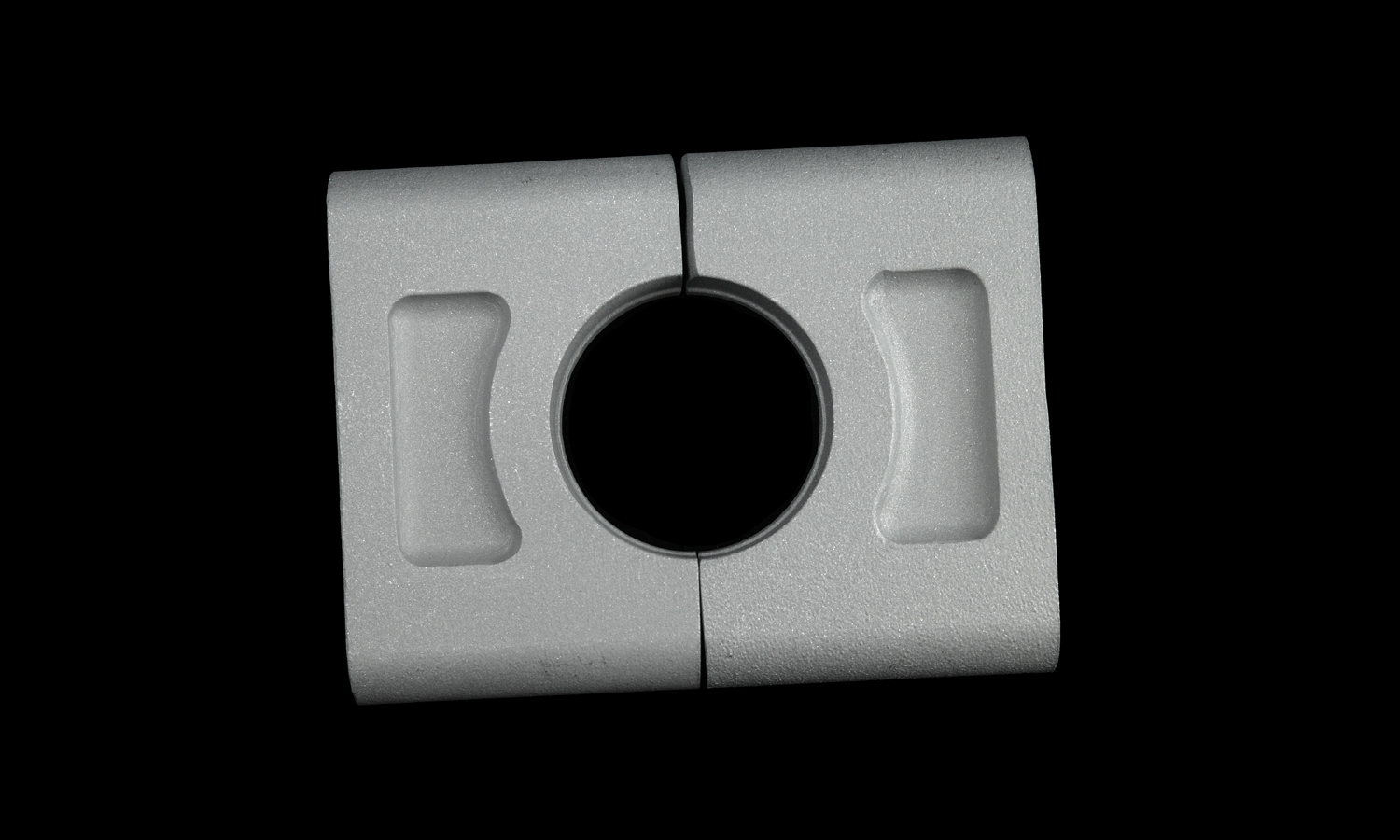

- SLM 3D Print Aluminum Saddle Clamp Customization

- Plan Ahead! View FacFox 2025 all-year Holiday Service Calendar Online!

Gallery

About Project

Crafted with precision and innovation, our Selective Laser Melting (SLM) 3D Printed Aluminum Alloy Saddle Clamps are engineered to offer exceptional support and reliability for your projects. These bespoke saddle clamps are the epitome of modern manufacturing, tailored to meet the exact needs of our clients.

Key Features:

- Material: Constructed from high-quality aluminum alloy, renowned for its lightweight, corrosion resistance, and remarkable strength, making it perfect for various mechanical and industrial applications.

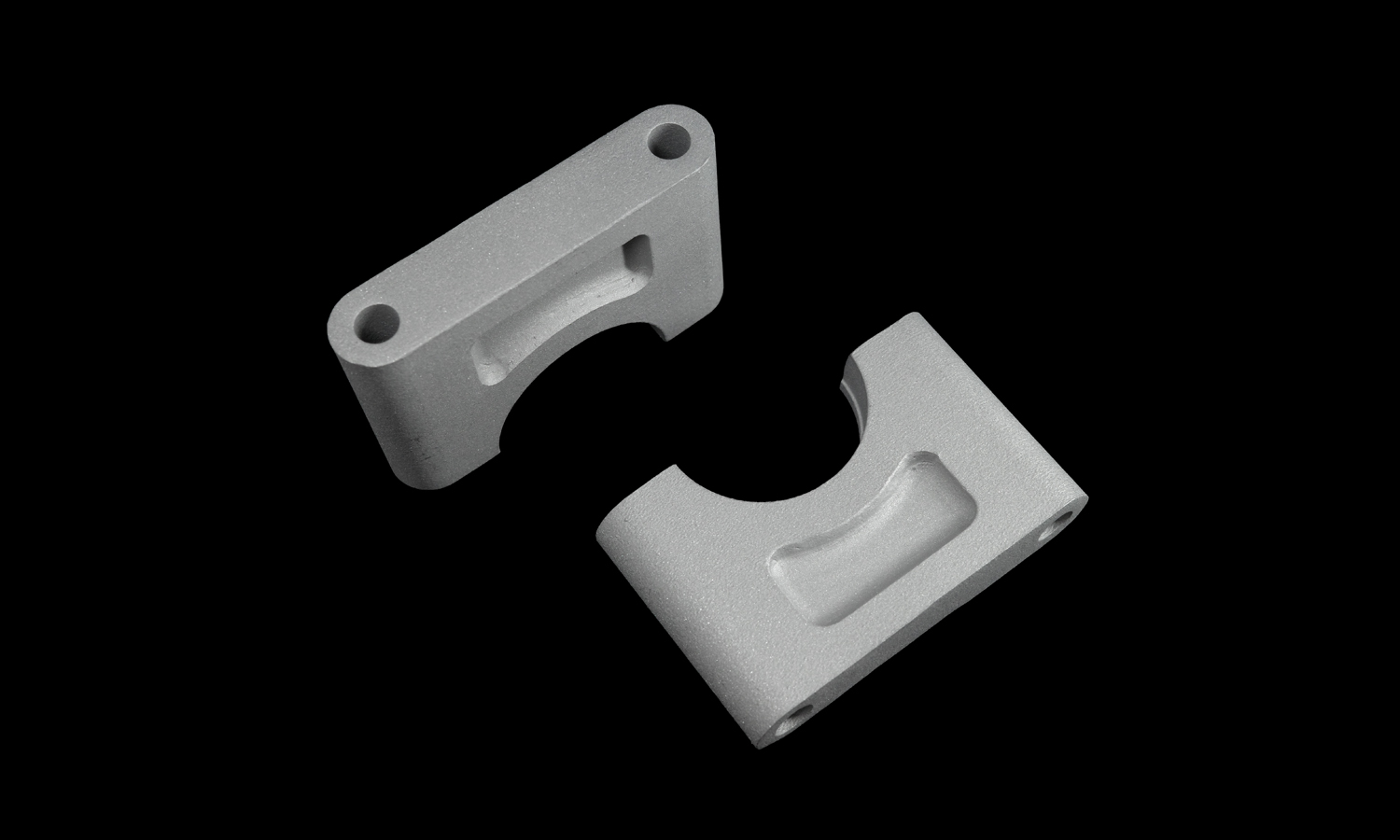

- Design: The saddle clamps feature semi-circular cutouts that snugly fit around pipes or cylindrical objects. This design ensures secure and sturdy support, while the mounting holes allow for easy and reliable attachment to surfaces.

- Customization: These clamps are customized for a specific client. We incorporate an allowance for further CNC machining, enabling precise adjustments to the dimensions. The client will also polish the parts and thread the holes using CNC, ensuring a perfect fit and finish.

Why Choose Our Saddle Clamps?

Our SLM 3D Printed Aluminum Alloy Saddle Clamps are designed to provide optimal support and secure fastening for pipes and cylindrical objects. Their robust construction and customizable features make them ideal for a wide range of applications, from plumbing to automotive systems.

Elevate Your Projects with FacFox’s Metal 3D Printing Service

FacFox is a leader in metal 3D printing, offering state-of-the-art solutions to bring your designs to life with unparalleled precision and efficiency. Our expertise in SLM 3D printing allows us to produce high-quality parts tailored to your exact specifications.

From raw finishing to detailed post-processing, we provide comprehensive services to meet your unique requirements. Whether you need parts with allowances for CNC machining or intricate designs polished to perfection, FacFox is here to deliver exceptional quality and innovative solutions.

Explore the future of manufacturing with FacFox’s metal 3D printing services and take your projects to the next level. Contact us today to learn more about how we can transform your ideas into reality with our cutting-edge technology!

Solution

- Step 1: 3D Model Creation. The initial design for the saddle clamp was created using computer-aided design (CAD) software, incorporating specific client requirements.

- Step 2: SLM 3D Printing. The 3D model was then processed for SLM 3D printing. A high-power laser beam was used to selectively melt and fuse layers of aluminum alloy powder, building the clamp layer by layer according to the digital design.

- Step 3: Part Removal. Once the printing process was complete, the finished clamp was carefully removed from the build platform.

- Step 4: Support Structure Removal. Any support structures used during the printing process were removed from the clamp using appropriate methods.