- SLA 3D Printed Resin Full-scale Sports Car Body Shell

- SLA 3D Printed Cold Storage Robot Resin Prototype

Gallery

About Project

Ever dreamed of stepping into the shoes of the Caped Crusader?This custom urethane rubber Batman cowl brings that fantasy to life – crafted with precision and built for serious cosplay.

Crafted with Precision

This cowl was created in collaboration with Shadow Studio FX, an industry-recognized team known for high-quality cosplay costume fabrication. Their artists and technicians specialize in custom accessories, armor, and full-body suits, offering professional craftsmanship to cosplayers of all levels.

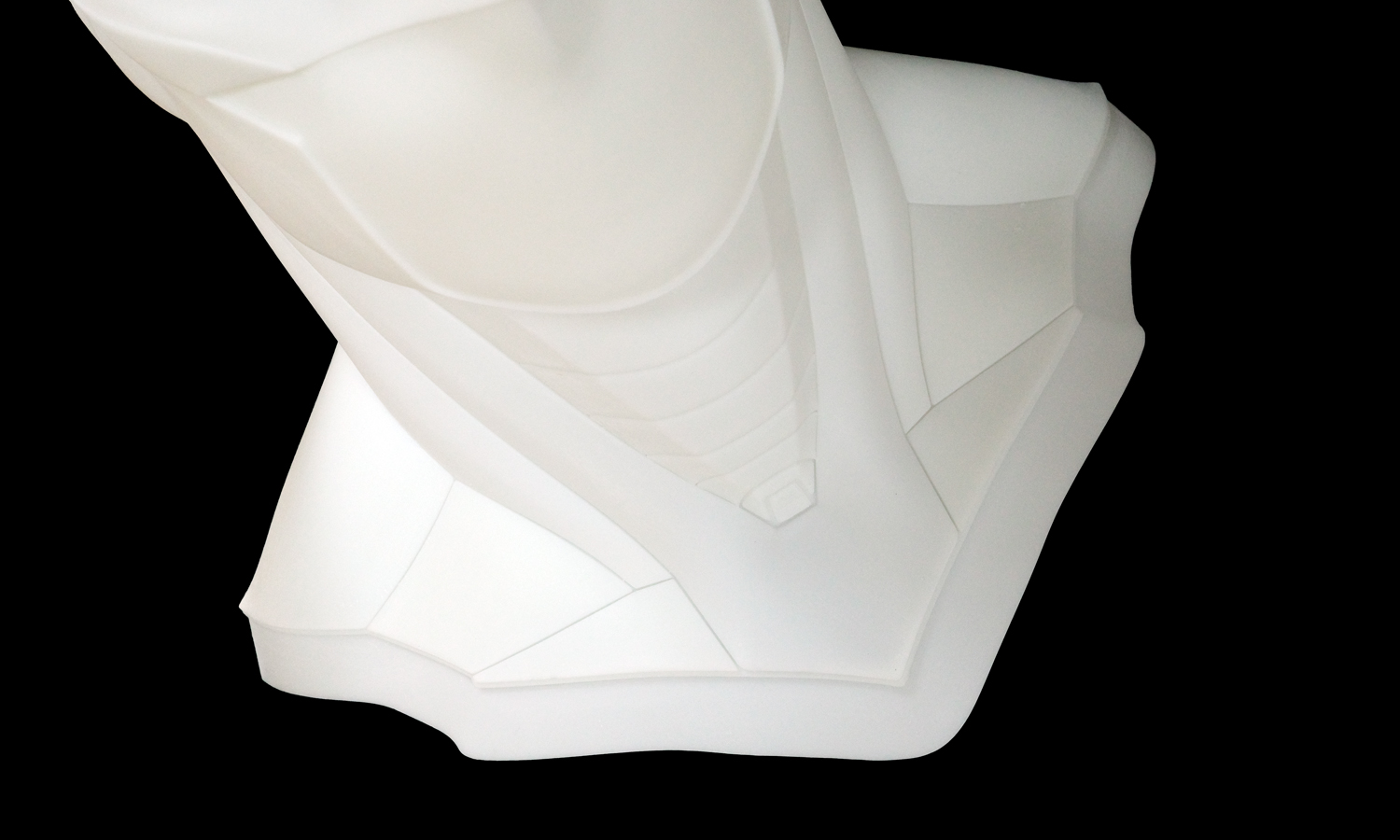

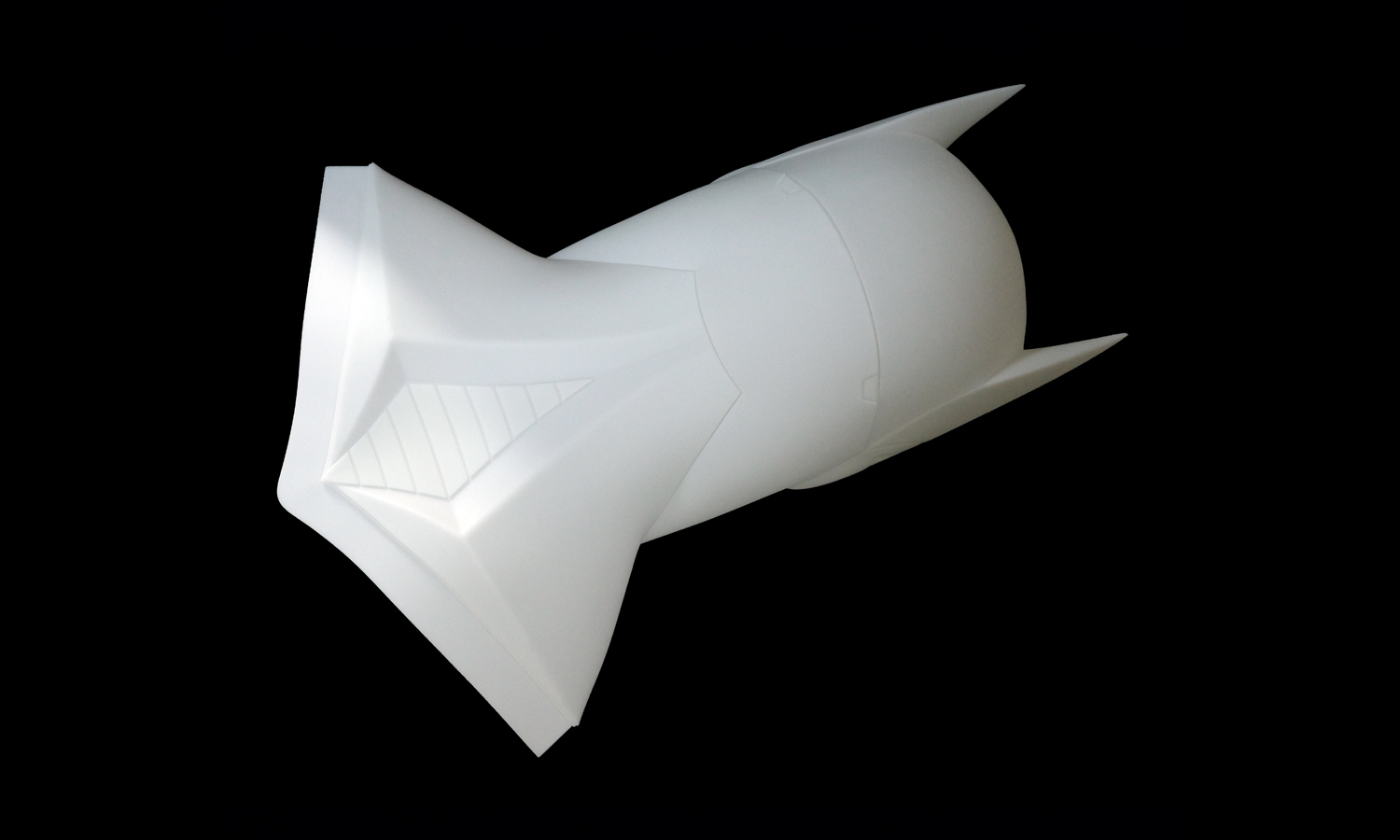

To achieve the sharp, clean forms of the master pattern, we used SLA Generic Resin – a smooth, highly detailed photopolymer ideal for props and molding patterns.Unlike grainier powder-based technologies, SLA delivers crisp edges, clean surfaces, and excellent mold-readiness, ensuring that every contour of the cowl transfers perfectly into the final urethane cast.

Once the master was completed, the final wearable piece was produced in durable urethane rubber, chosen for its flexibility, tear resistance, and ability to capture fine details during casting.

Why Choose This Cowl?

- Lightweight & comfortable: The hollow structure ensures airflow and reduces long-wear fatigue.

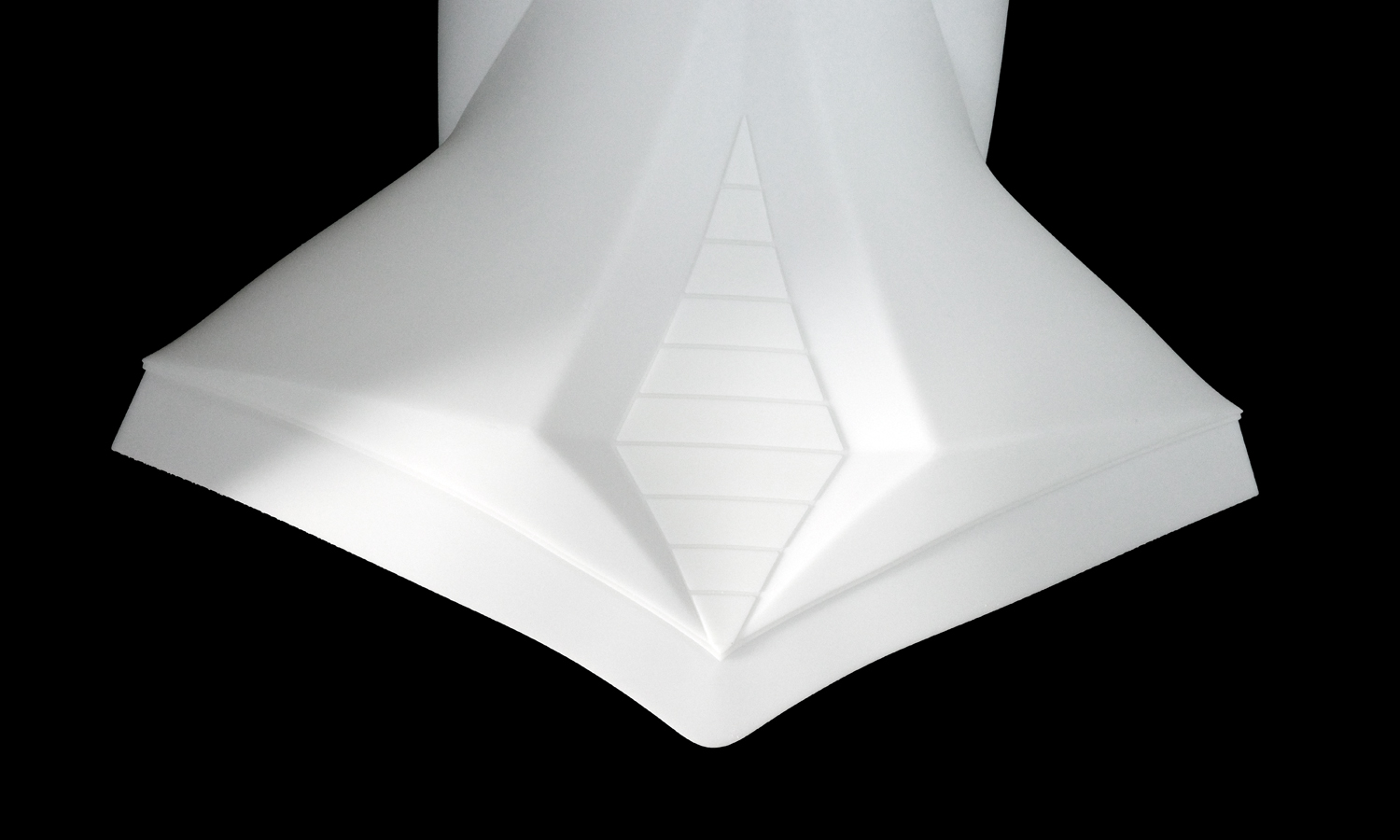

- Accurate silhouette: The iconic bat-ears and angular cheek lines stay faithful to classic Batman forms.

- Premium finish: SLA master + urethane cast = a professional-grade prop with clean geometry and smooth surfaces.

- Cosplay-friendly: Strong, flexible urethane rubber holds up to conventions, travel, and photography sessions.

Want to Create Your Own Custom Cowl?

Reach out to Shadow Studio FX to bring your character concept to life.And for high-detail 3D printing, molding masters, and prop-making support, FacFox is ready to assist.

About Shadow Studio FX

- 10+ years of experience in custom cosplay fabrication

- Expertise in cowls, armor, props, and full-body suits

- Strong focus on professional finish and durability

- Competitive pricing with tailored project support

Solution

- Step 1: Design Creation. The Batman cowl was meticulously designed by Shadow Studio FX, capturing the angular silhouette and signature bat-like ears.

- Step 2: 3D Model Preparation. A detailed 3D model was built in CAD software and exported as an STL file for printing.

- Step 3: Slicing. The STL file was sliced into thin layers with parameters optimized for high-resolution SLA printing.

- Step 4: 3D Printing. The master pattern was printed using SLA Generic Resin, producing crisp edges, smooth surfaces, and accurate geometric details.

- Step 5: Post-Processing. The printed master was cleaned, supports were removed, and the surface was sanded and refined to achieve a smooth, mold-ready finish.

- Step 6: Mold Making. A negative mold was created using the SLA master, ensuring every contour and detail of the cowl was accurately captured.

- Step 7: Casting. Flexible urethane rubber was poured into the mold and left to cure, forming the final wearable cowl.

- Step 8: Finishing. The cured cast was demolded, trimmed, and refined to remove minor imperfections.

- Step 9: Quality Check. The finished cowl underwent a detailed inspection to ensure durability, surface quality, and faithful design reproduction.