- DMLS 3D Printed Titanium Tobacco Pipe with Colorful Glass Tube

- FDM 3D Printed Multi-color PLA Futuristic Mechanical Bee

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

Imagine a world where your health and wellness hub seamlessly integrates with your daily routine. Introducing the developing Health Hub, a sleek and versatile gadget designed to revolutionize your approach to fitness.

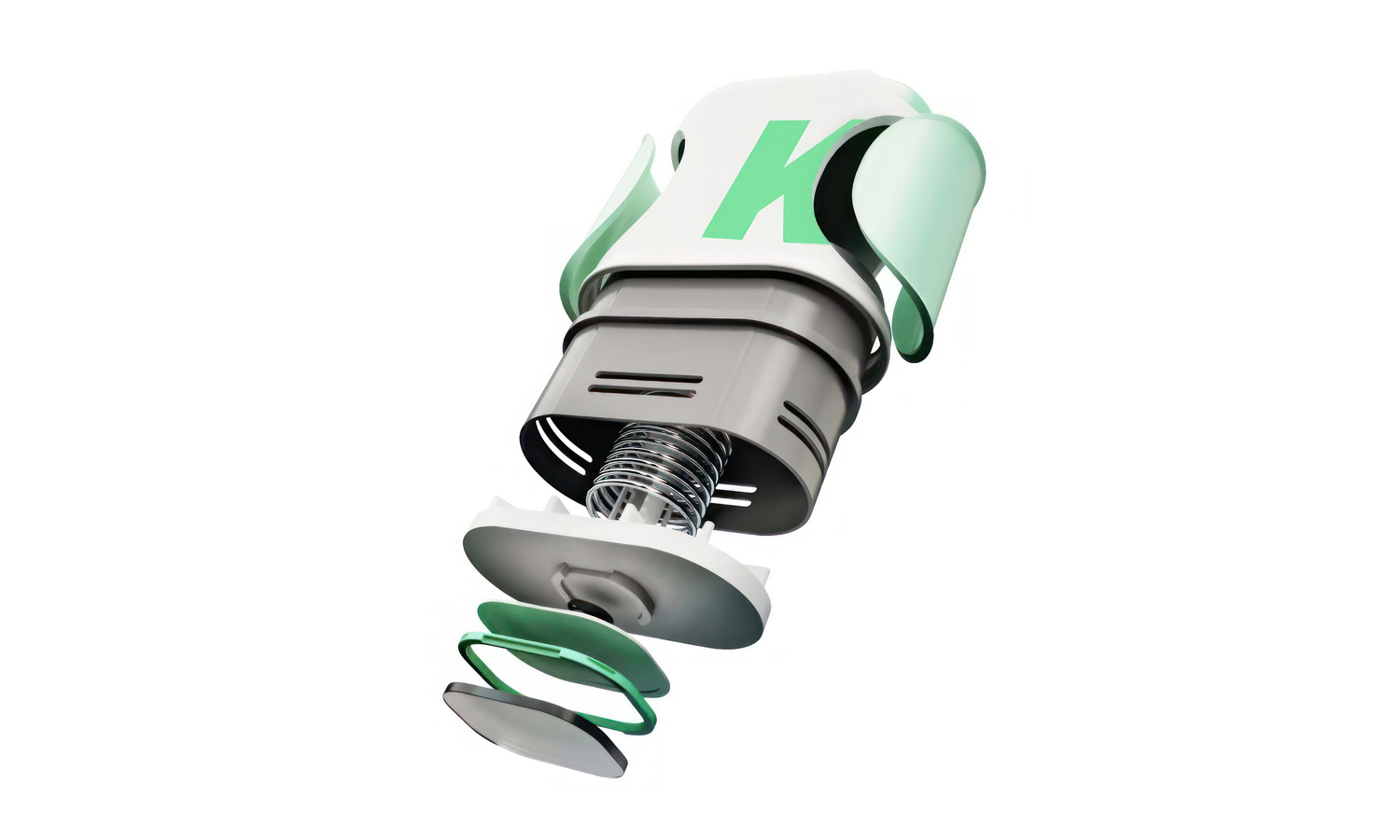

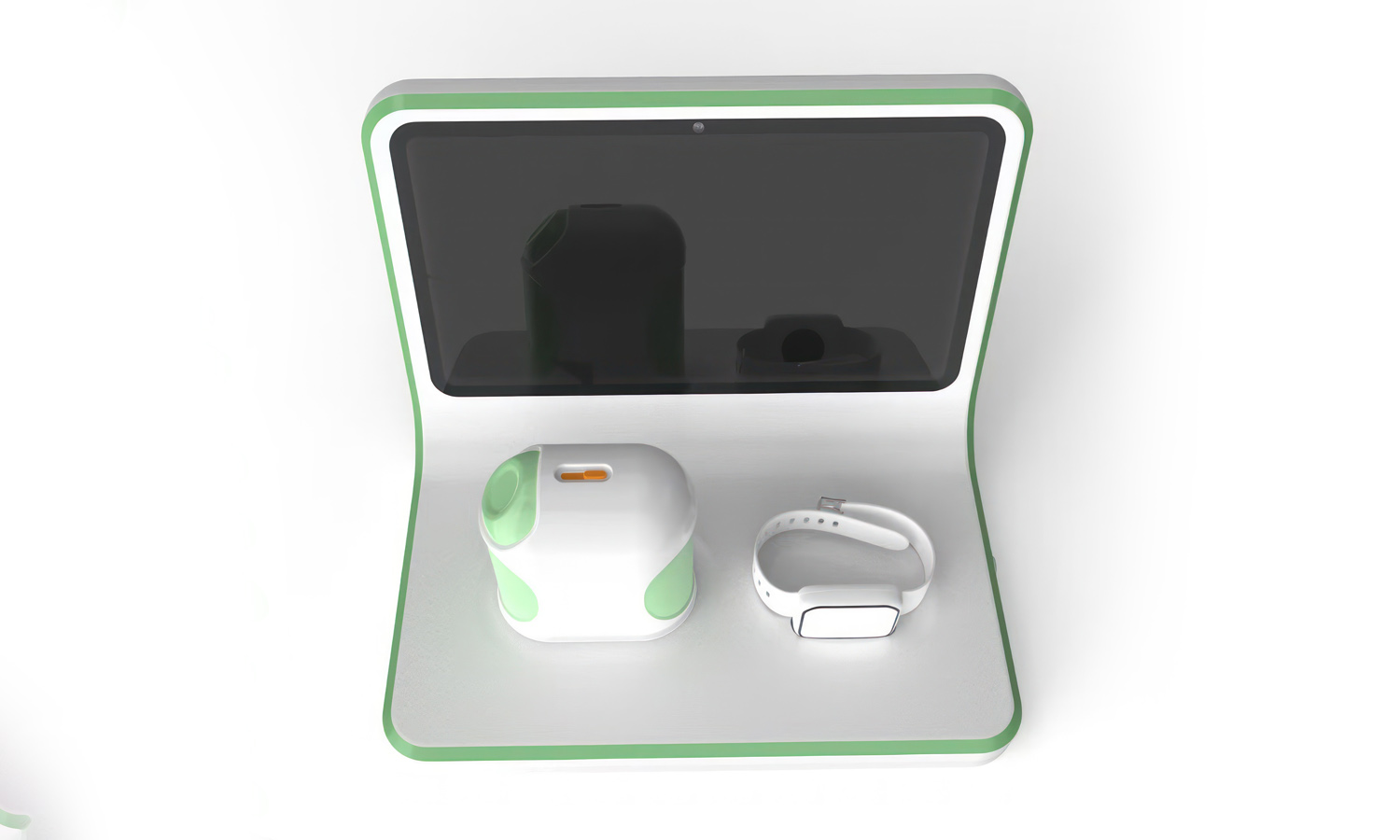

This innovative device features a curving white and light green pad positioned on a rotatable round base. The flat portion of the pad acts as a wireless charging station, keeping your K-branded smartwatch and wireless earpiece powered up and ready to go. But the functionality doesn’t stop there!

The upper part of the pad boasts a built-in screen that displays a range of health-centric features. This screen can showcase statistics collected by your smartwatch, providing valuable insights into your activity levels and overall well-being. Imagine glancing down and seeing your heart rate, step count, or even receiving personalized exercise recommendations based on your data.

But wait, there’s more! The Health Hub can also display educational lessons, transforming your charging station into a miniaturized fitness coach. Learn new workout routines, explore healthy recipes, or gain valuable knowledge about nutrition – all within arm’s reach.

The Health Hub prototype is a testament to the power of SLA 3D printing. This cutting-edge technology allows for the creation of highly detailed and functional prototypes, perfect for bringing innovative ideas to life. The smooth, high-resolution finish of the SLA print showcases the potential for a visually stunning end product.

Looking to develop your own groundbreaking health and wellness gadget? FacFox can help! With our industry-leading SLA 3D printing services, we can transform your vision into a tangible reality. Our team of experts will work closely with you to ensure your prototype meets the highest standards of quality and functionality. Contact FacFox today!

Solution

- Step 1: Design Creation. The 3D model of the Health Hub was designed using CAD software. The design included the curving pad, rotatable round base, wireless charging station, and screen.

- Step 2: Preparation of the SLA Printer. The SLA 3D printer was prepared by filling the resin tank with white photopolymer SLA Generic Resin.

- Step 3: Slicing the Model. The 3D model was sliced into thin layers using slicing software. The sliced file was then uploaded to the SLA printer.

- Step 4: Printing the Prototype. The SLA printer was activated, and the laser selectively cured the resin layer by layer, building up the Health Hub prototype from the bottom up.

- Step 5: Post-Processing. Once printing was completed, the prototype was carefully removed from the build platform. The excess resin was drained, and the prototype was washed in isopropyl alcohol to remove any uncured resin.

- Step 6: Curing. The washed prototype was placed in a UV curing chamber to fully harden the resin, ensuring durability and stability.

- Step 7: Surface Finishing. The cured prototype was sanded and polished to achieve a smooth surface finish. Any support structures were removed during this process.

- Step 8: Assembly. The various components of the Health Hub, including the curving pad, rotatable base, and screen, were assembled. The wireless charging station was integrated into the flat part of the pad.

- Step 9: Painting and Detailing. The prototype was painted in its main colors, white and light green. The large “K” logo was added to the earpods case and smartwatch.

- Step 10: Functional Testing. The assembled prototype was tested to ensure that the wireless charging station worked correctly and that the screen displayed the necessary statistics, exercise advice, and lessons.

- Step 11: Final Inspection. A thorough inspection was conducted to verify the quality and functionality of the Health Hub prototype. Any necessary adjustments were made to meet the design specifications.