- SLM 3D Printed Aluminum Housing with Aerospace Isogrid Reinforcement

- SLA 3D Printed Ernie Kaltenbrunner Resin Statue

Material Plastic, Metal

Quantity 40 pcs

Price Range $100-1,000

Lead Time 2 workdays

Gallery

About Project

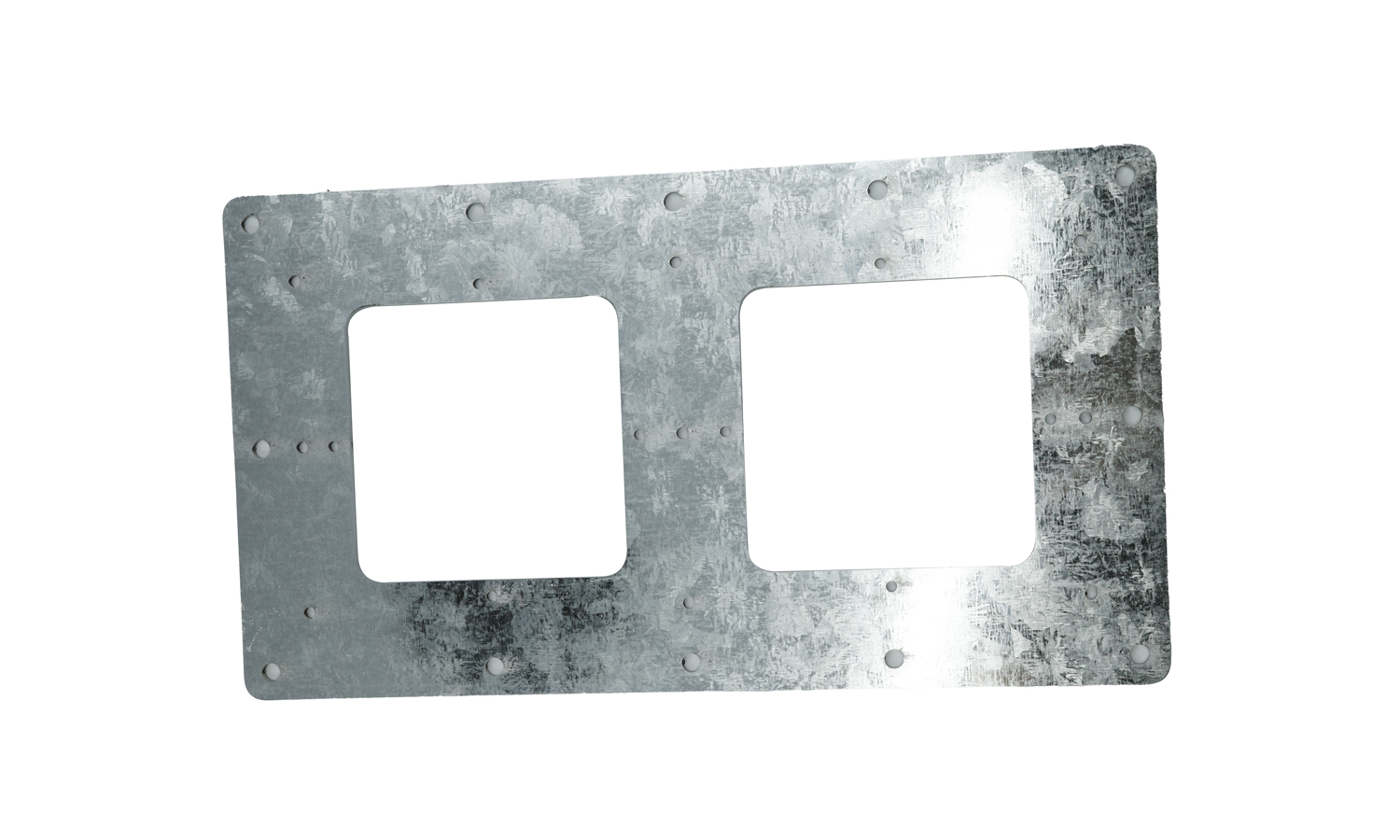

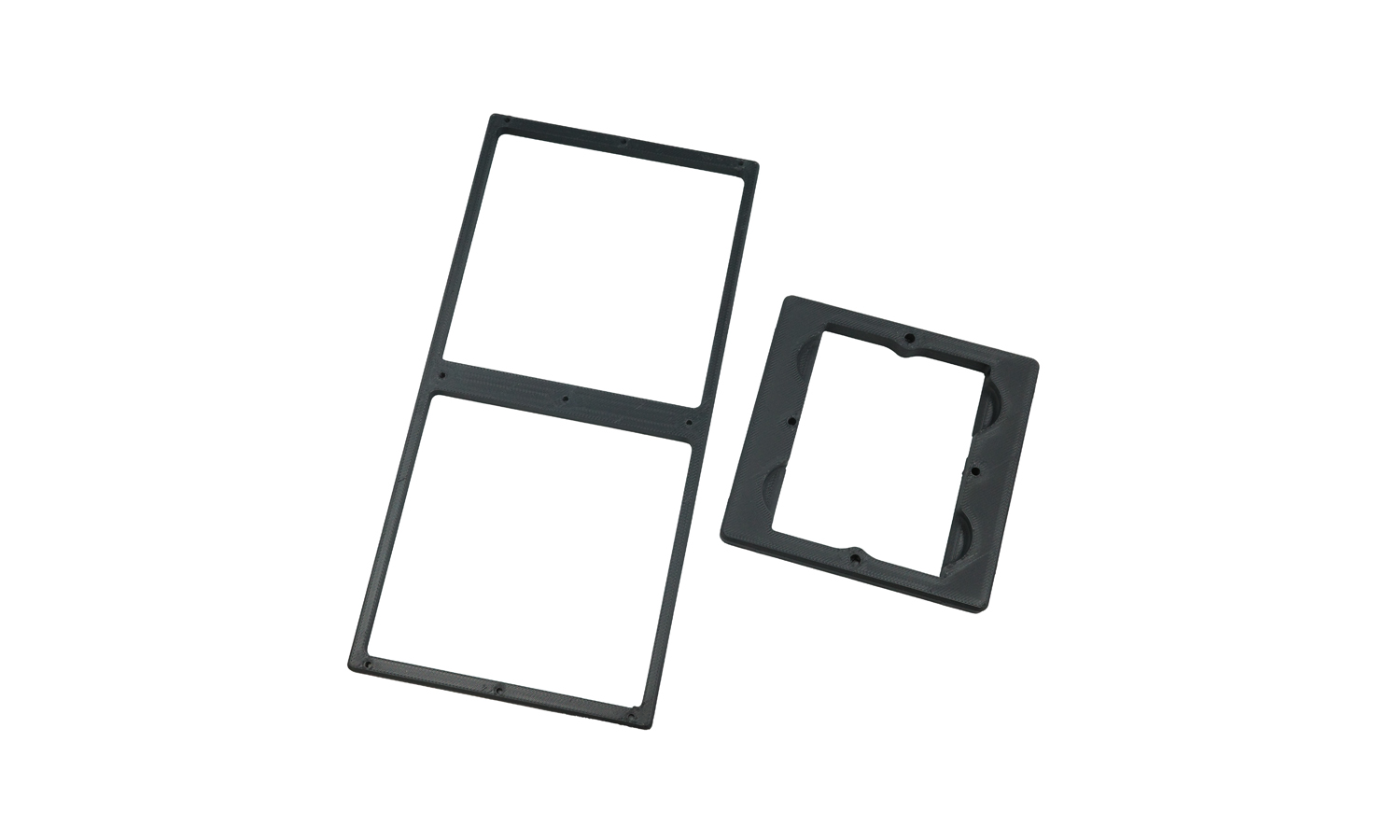

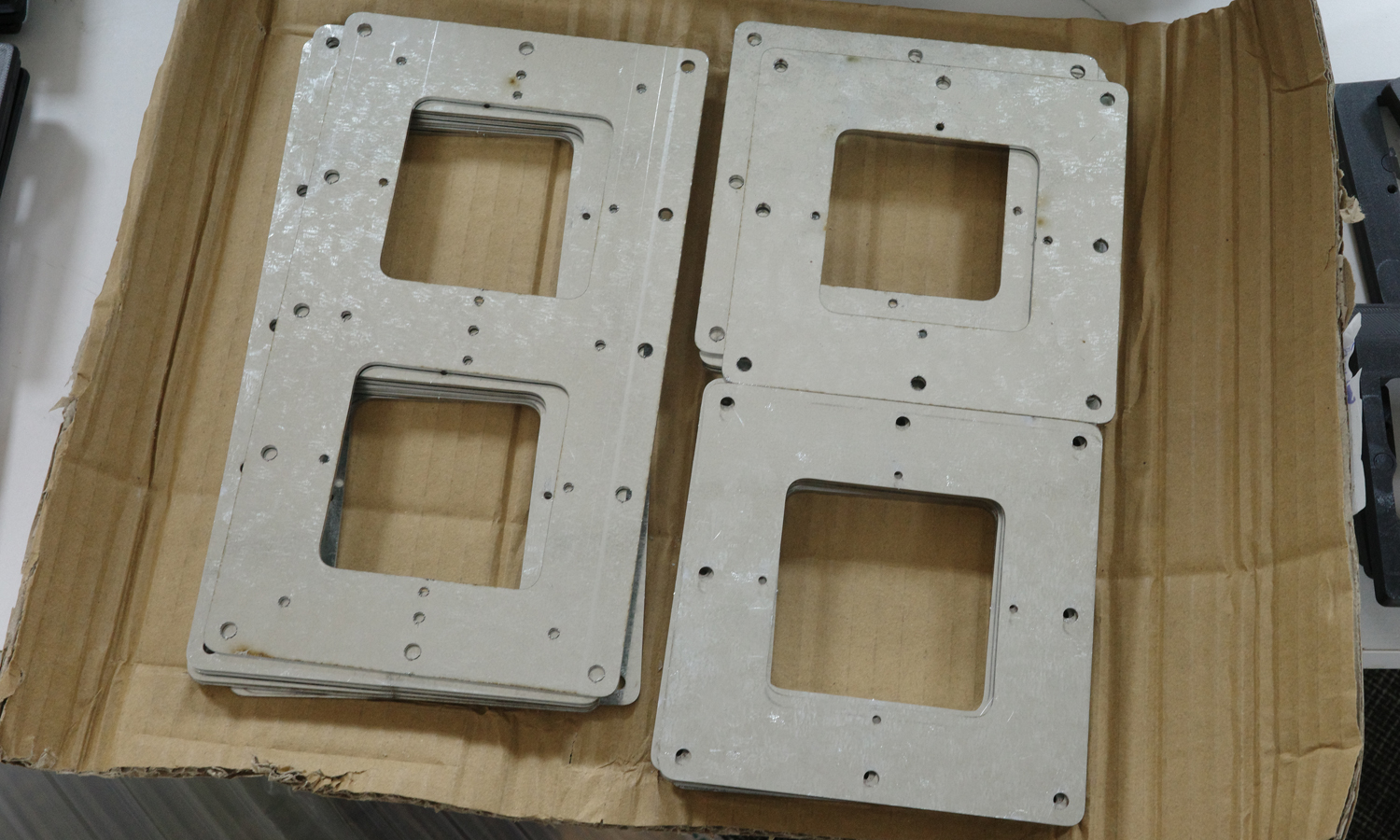

From precise industrial fabrication to rapid custom prototyping, achieving the perfect fit between disparate materials is a hallmark of quality engineering. These recent images showcase a set of galvanized steel plates and 3D printed PLA frames, specifically designed for seamless assembly.

The Materials: Strength Meets Versatility

The project highlights two very different but complementary manufacturing processes:

- Laser Cut Galvanized Steel: These plates offer exceptional structural integrity and corrosion resistance. The laser cutting process ensures that the internal square cutouts and the complex array of mounting holes are perfectly aligned across both the single and double-plate configurations.

- 3D Printed PLA Frames: The black PLA components serve as the interface layer. 3D printing was chosen here for its ability to create complex geometriesŌĆölike the recessed screw bosses and reinforced cornersŌĆöthat would be difficult or costly to machine from metal.

Precision Engineering for Perfect Assembly

The design intent is clear: the PLA frames act as a “gasket” or housing that nests against the galvanized steel.

- Alignment: The hole patterns on the steel plates match the integrated mounting points on the 3D printed frames exactly.

- Modularity: With both single and double-window versions, the system is designed to be scalable for different electronic or mechanical housing needs.

- Surface Finish: The “spangle” finish of the galvanized steel provides a rugged, industrial aesthetic, while the fine layer lines of the PLA offer a clean, matte contrast.

Whether these are for specialized electrical enclosures, mounting brackets, or architectural features, the combination of metal and polymer ensures the final assembly is both lightweight and incredibly durable.

Custom Manufacturing with FacFox

If you are looking to bring a multi-material project like this to life, FacFox is your one-stop shop for professional manufacturing. We offer high-precision Fiber Laser Cutting for a variety of metals, including galvanized steel, aluminum, and stainless steel. Pair your metal components with our industrial-grade 3D Printing services, spanning FDM, SLA, and SLS technologies. At FacFox, we specialize in helping engineers and designers bridge the gap between digital models and physical products with fast turnaround times and competitive pricing.

Solution

- Step 1: The structural components were designed using CAD software to ensure perfect hole alignment between the metal and plastic parts.

- Step 2: The galvanized steel sheets were loaded onto a high-precision fiber laser cutting machine.

- Step 3: The square apertures and mounting holes were laser-cut from the steel plates with tight tolerances.

- Step 4: The complementary frames were 3D printed using PLA filament via Fused Deposition Modeling (FDM) technology.

- Step 5: Recessed screw bosses and internal geometries were integrated into the PLA prints to facilitate flush mounting.

- Step 6: All components were deburred and inspected to confirm that the metal plates and plastic frames nested together seamlessly.