- SLA 3D Printed Cartoon Giraffe Bookcase Scaled-down Prototype

- SLM 3D Printed SS316L Hollowed Sphere Plated with Chrome

Material Resin

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

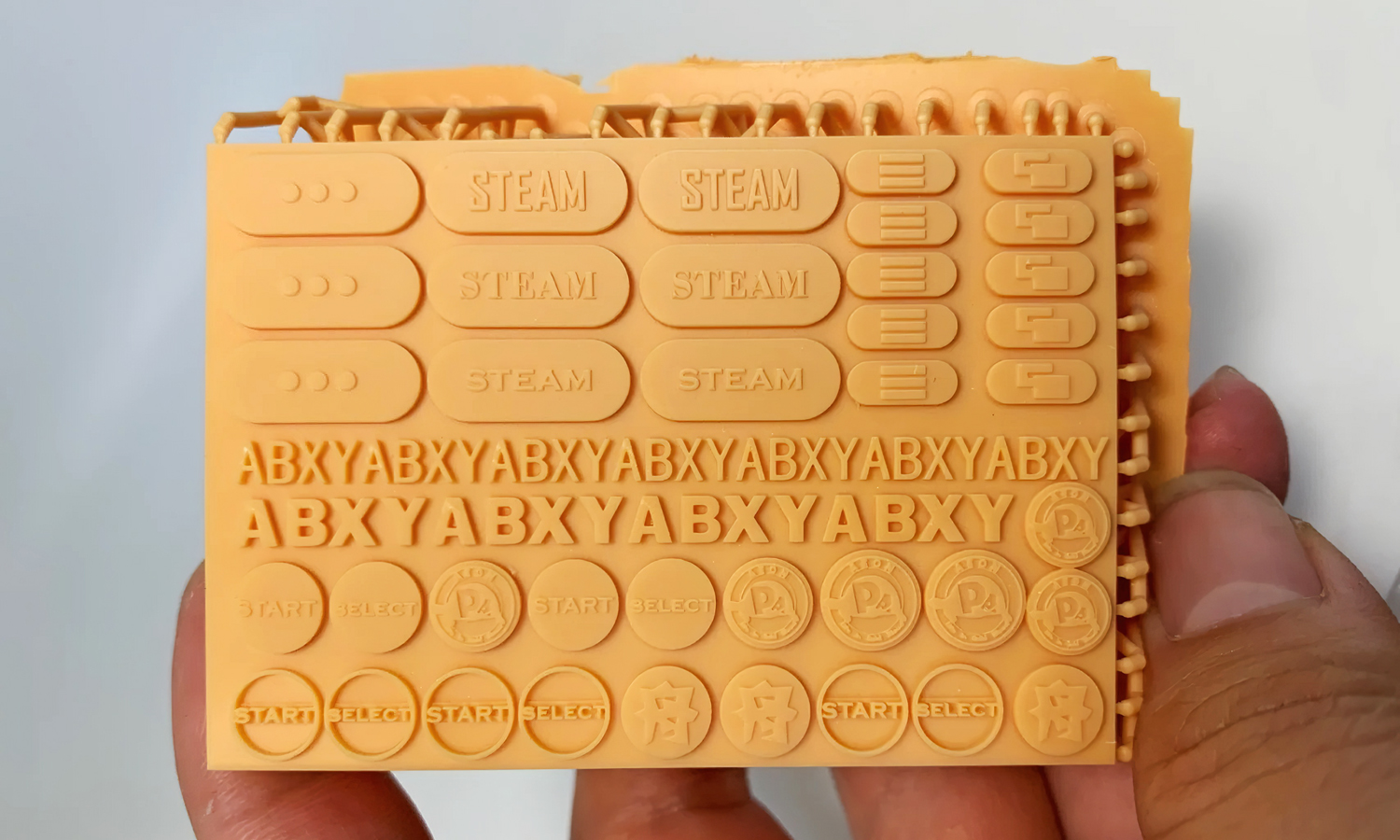

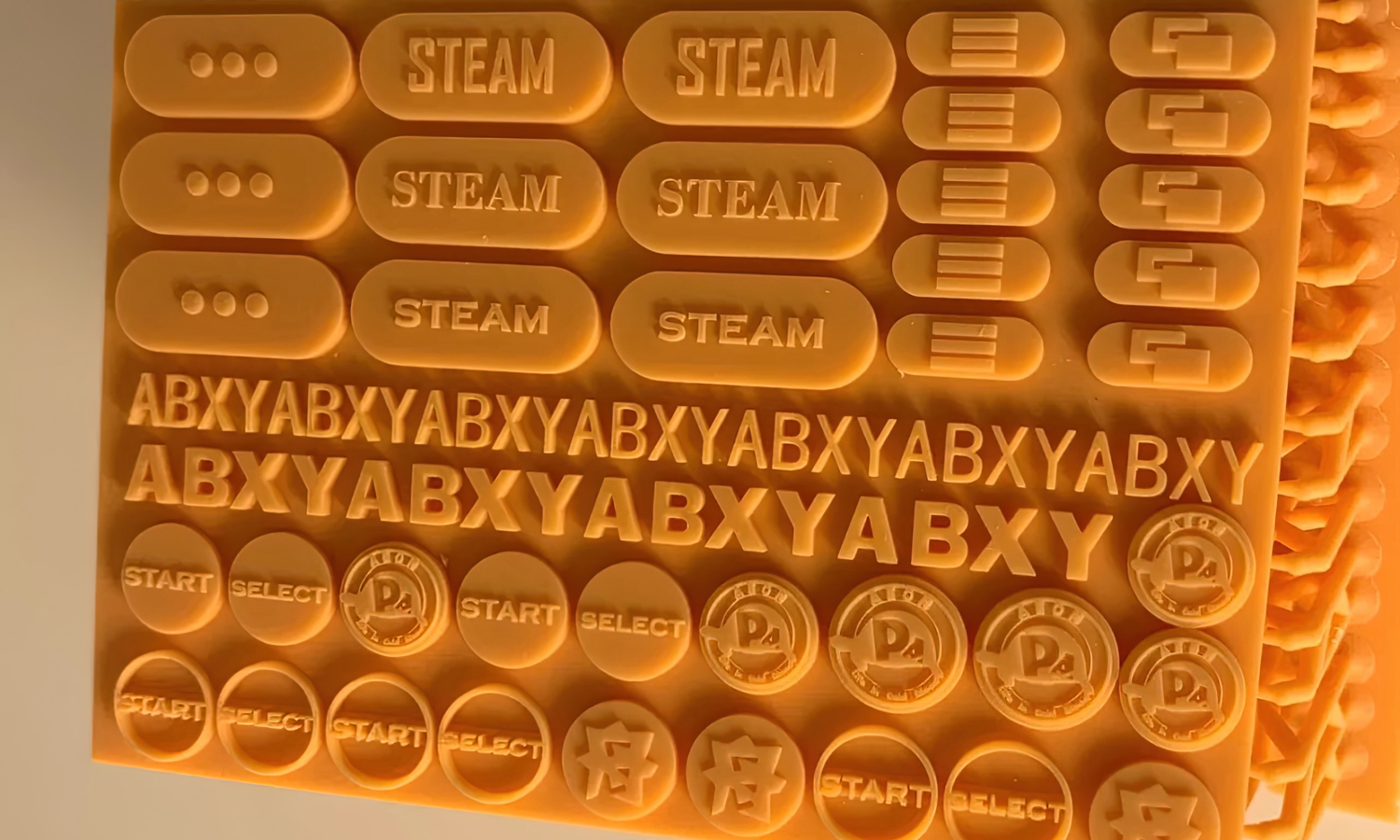

Calling all retro enthusiasts and custom console creators! Get ready to elevate your projects with breathtakingly detailed game console buttons, crafted using cutting-edge DLP 3D printing technology.

Imagine this: a vibrant sheet of yellow plastic, transformed into a tactile playground of familiar symbols. ŌĆ£STEAMŌĆØ boldly declares its presence, alongside the iconic ŌĆ£STARTŌĆØ and ŌĆ£SELECTŌĆØ duo. Each button, from the classic ŌĆ£AŌĆØ, ŌĆ£BŌĆØ, ŌĆ£XŌĆØ, and ŌĆ£YŌĆØ to any custom design you desire, is meticulously rendered with pinpoint precision. The crisp lines, smooth curves, and raised lettering practically beg to be pressed.

But this isn’t just about aesthetics. These DLP 3D-printed buttons are built to last. The robust material can withstand the rigors of molding, ensuring your custom controllers emerge ready for epic gaming sessions. No more blurry logos or mushy buttons ŌĆō every detail is preserved with stunning clarity.

The possibilities are endless. Breathe new life into a vintage console with replacement buttons that surpass the originals. Design your own controller, emblazoned with your clan’s emblem or a personalized catchphrase. The choice is yours, and DLP 3D printing brings your vision to life with uncompromising quality.

Ready to level up your game? FacFox has all the tools you need. Our expert team specializes in high-resolution DLP 3D printing and precision molding, making us the perfect partner for your custom console button dreams. We offer a wide range of materials, colors, and finishes to perfectly match your vision.

So, put down the generic controllers and step into a world of personalized gaming. Contact FacFox today and let us help you craft the buttons that will make your console the envy of every gamer.

Solution

- Step 1: High-resolution models of iconic console buttons (e.g., “STEAM”, “A”, “B”, “X”, “Y”) were meticulously crafted in a virtual realm, ensuring precise rendering of every detail.

- Step 2: Guided by a meticulous laser beam, a DLP 3D printer meticulously translated the digital models into tangible button replicas, layer by delicate layer. Liquid DLP Ultra Detail Resin transformed, solidifying into miniature sculptures boasting crisp lines and smooth surfaces.

- Step 3: Bathed in a cleansing solution, the newly formed buttons shed any remnants of their liquid origins, emerging fully formed. Then they were dried and prepare for molding.