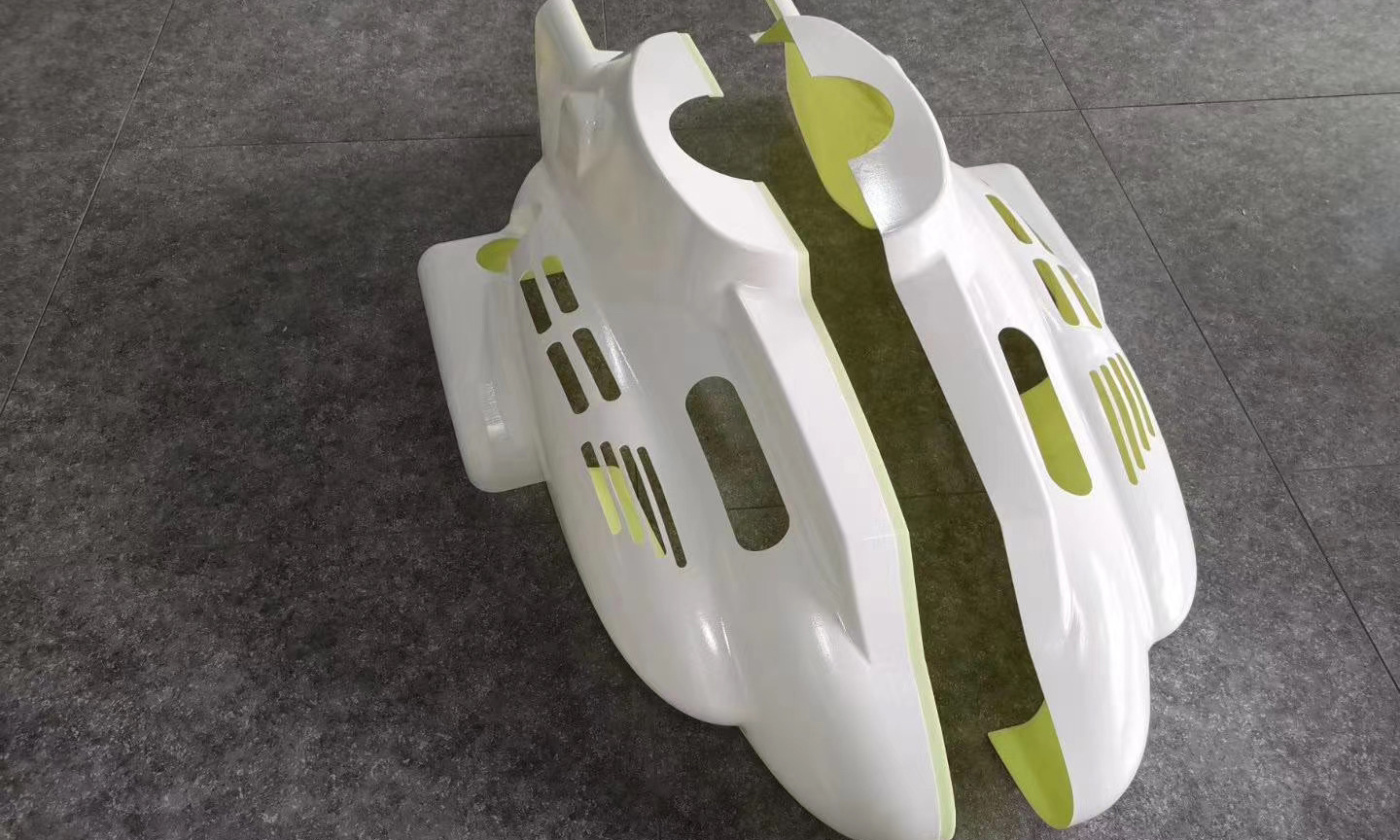

SLA 3D Printed Unmanned Helicopter Enclosure

Posted on 2020-10-20 in Drone ┬Ę µŚĀõ║║µ£║

Gallery

About Project

Unmanned aerial vehicles (UAV) have come a long way since their first use in World War I. While UAV development has occurred primarily in defense operations, recently UAVŌĆÖs have been developed for civil and commercial applications.

Rapid advances in technology are enabling UAVŌĆÖs more capabilities in smaller frames; one of those technologies is 3D printing, also called additive manufacturing. With the design freedom allowing for part consolidation and lighter parts, 3D printing has significantly contributed to the development of UAVŌĆÖs and their latest applications.

Our client has entered the unmanned helicopter market and designed this one as shown in the above images for geographic mapping and aerial survey purposes.

Solution

- Step 1: Examine the 3D models offered by our client. We mainly focus on the layer thickness, the snap-fit structure, the minimum details, etc. After ensuring the model is printable, we input the STL files into our large-format industrial SLA 3D printer.

- Step 2: As the enclosure is printed for the end-use product, we recommend using SLA Tough Resin(White). It has better stiffness and impact resistance than generic resin, and can produce parts with improved mechanical properties. The maximum size we can print with this material is 1700 x 900 x 800 mm.

- Step 3: Take out the print from the 3D printer, clean off excess materials, polish to remove the marks, and post-cure them with UV. Test assembling the parts and make small adjustments with tools.