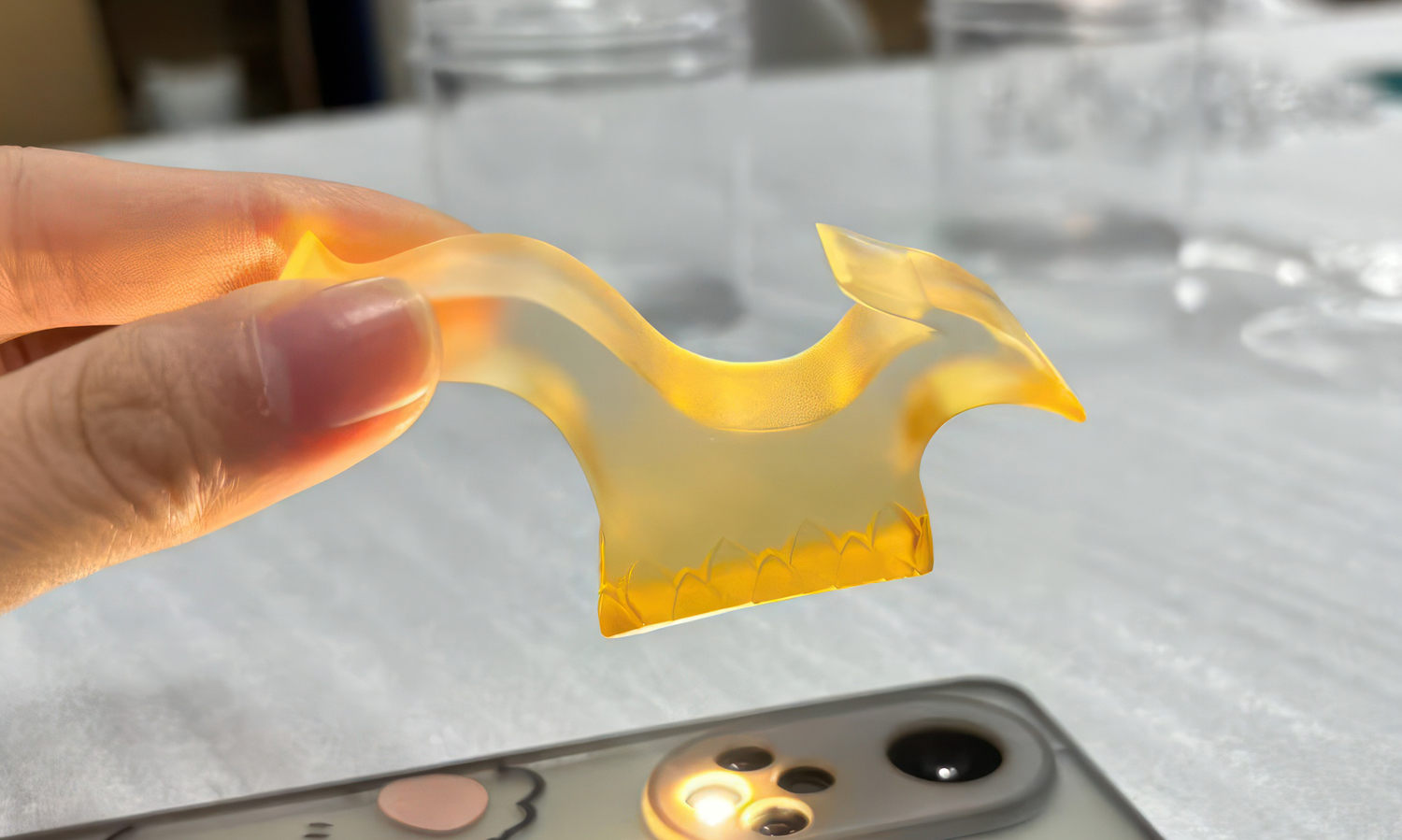

SLA 3D Printed Frosted & Dyed Clear Resin Parts

Posted on 2025-09-12 in Consumer В· ж¶Ҳиҙ№е“Ғ

Process 3D Print, Support Removal, Post Curing, Polish, Paint

Material Resin

Quantity 10 pcs

Price Range $100-1,000

Lead Time 3 workdays

Material Resin

Quantity 10 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

At FacFox, we believe post-processing transforms a good print into a stunning showcase piece. These frosted clear 3D prints are the perfect example – starting from high-resolution SLA clear resin prints, then meticulously polished, sand-blasted, and dyed into vibrant jewel-like tones.

- Frosted Elegance – Sand-blasting creates a soft matte finish that diffuses light beautifully, turning transparency into a frosted glass effect.

- Rich Color Gradients – Transparent dyes add depth, vibrancy, and even smooth transitions between hues for a premium artistic touch.

- Premium Feel – The surface is silky and uniform, elevating prototypes, collectibles, and display models far beyond raw prints.

- Versatile Applications – Perfect for art toys, luxury packaging prototypes, architectural elements, and decorative designs.

Whether you’re designing a prototype that needs to impress investors, or a limited-edition art toy that must look flawless, FacFox’s frosted clear finishing brings clarity, color, and class to your 3D prints.

рҹ‘ү Ready to give your designs a frosted, luxurious finish? Contact FacFox today and let’s make your ideas shine.

Solution

- Step 1: Model Preparation. The 3D model was prepared and oriented in slicing software for SLA printing. Supports were added to ensure dimensional stability.

- Step 2: Printing. The parts were printed with clear resin using SLA technology, ensuring fine resolution and smooth surfaces.

- Step 3: Support Removal. The printed parts were cleaned and the supports were carefully removed to avoid surface damage.

- Step 4: Polishing. The surfaces were polished to eliminate visible layer lines and to restore clarity in the resin.

- Step 5: Sand-blasting. A fine abrasive blasting process was applied, giving the prints a uniform frosted finish and diffused translucency.

- Step 6: Dyeing. The frosted prints were immersed in transparent dyes, creating vibrant colors and smooth gradient effects.

- Step 7: Final Inspection. Each piece was inspected to ensure the surface quality, color consistency, and overall aesthetic met the required standards.