- DMLS 3D Printed Titanium Alloy Crab Claw Keychain

- Automotive Lighting Prototypes Built with SLA Clear Resin

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

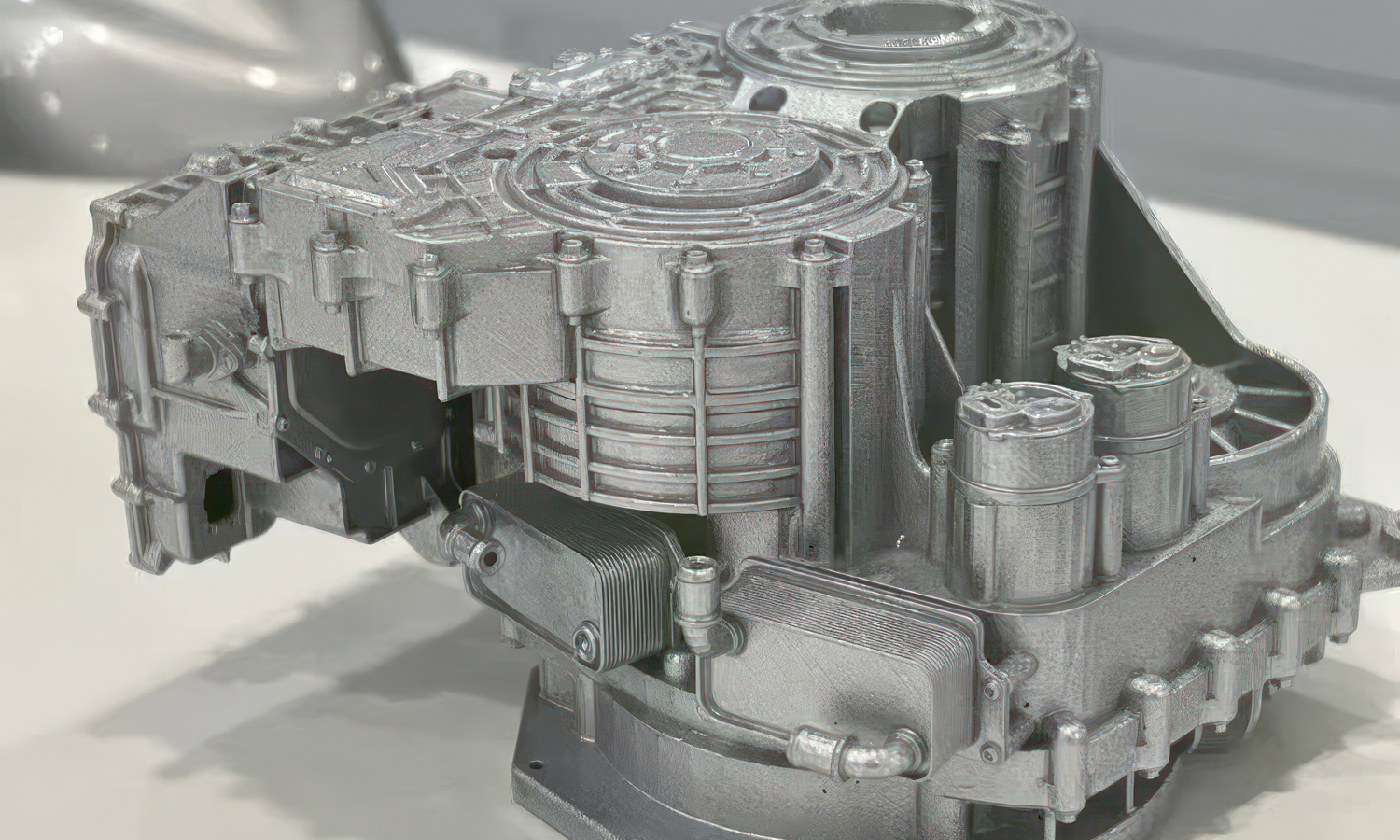

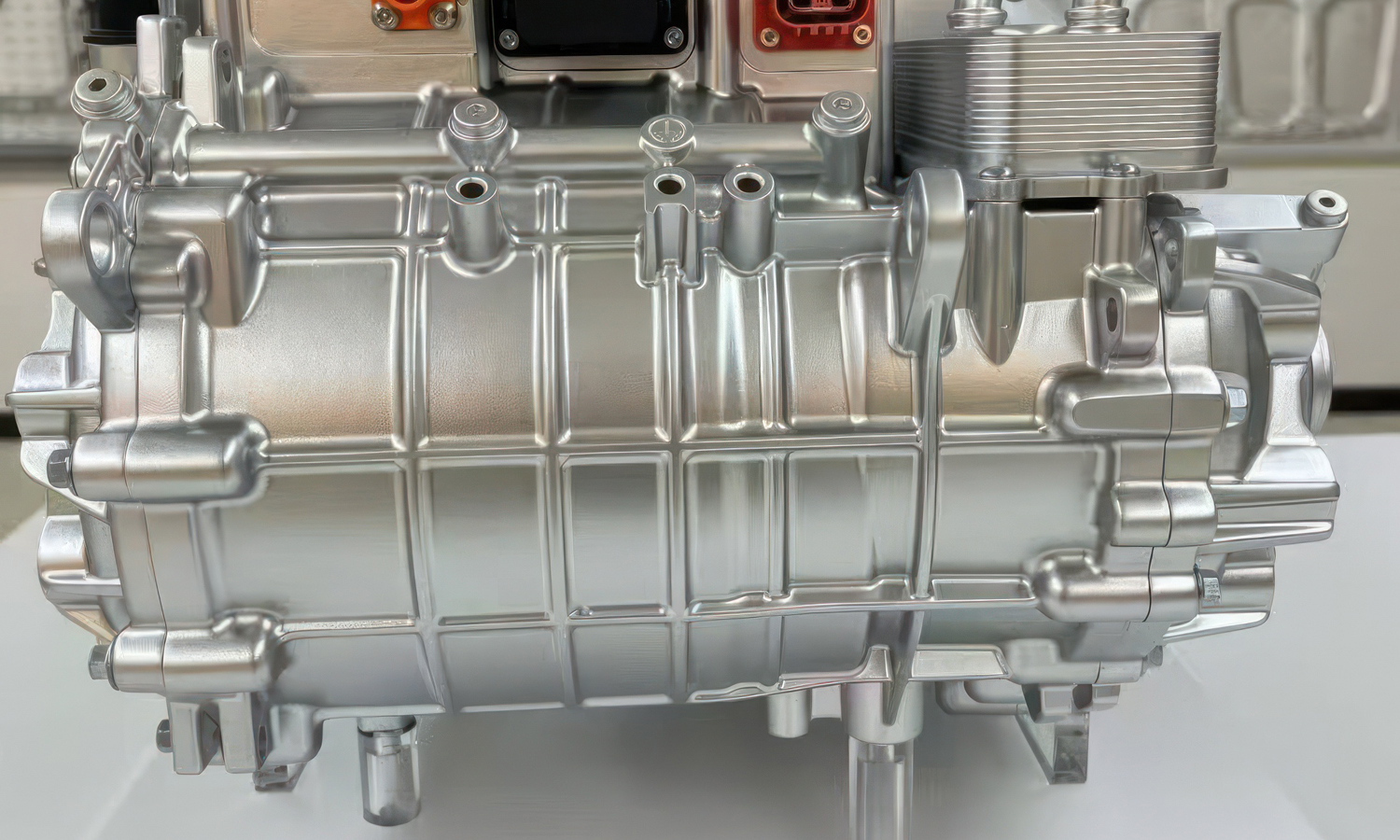

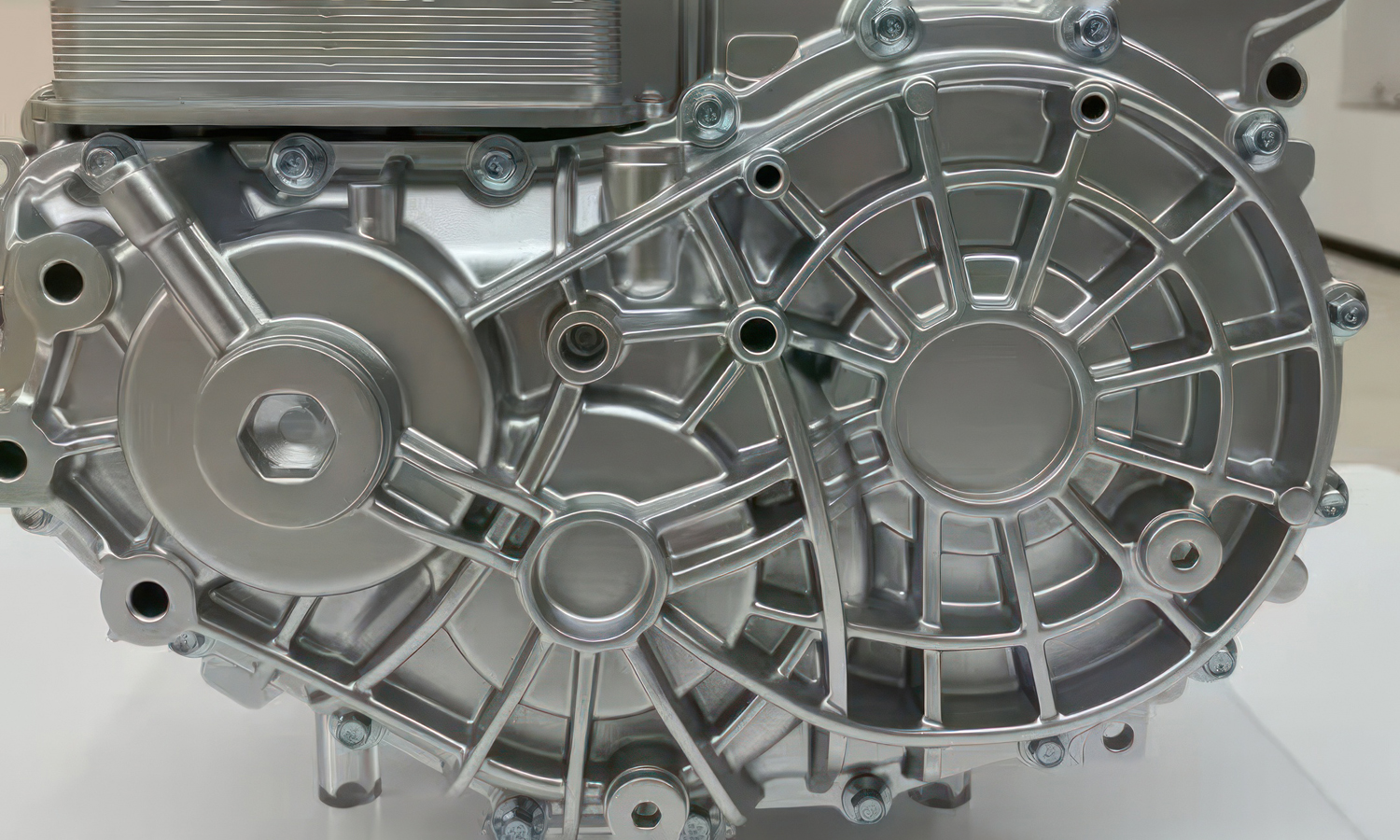

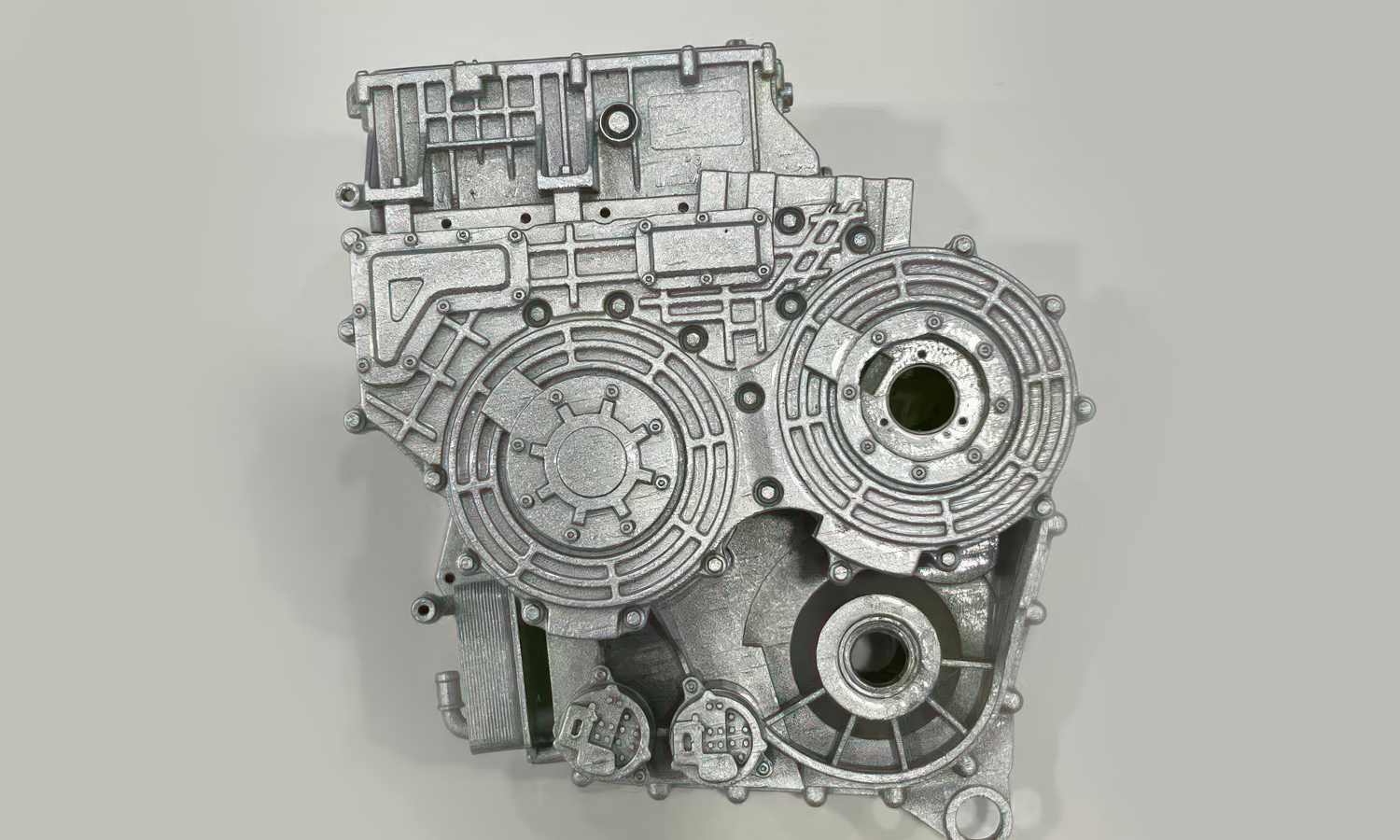

This intricate metallic-looking part is a highly detailed automotive transmission housing model, reproduced through high-precision 3D printing. The component replicates the complex structure of a real transmission assembly, including the gear housing, fluid channels, cooling interfaces, and bolt patterns – all faithfully recreated to demonstrate engineering integrity and manufacturability.

Design and Visual Description

The model showcases multiple interlocking cylindrical chambers, ribbed reinforcement walls, and a dense network of geometric surfaces that capture the functional and aesthetic complexity of real automotive components. Every rib, mounting boss, and connection port is accurately presented, demonstrating how 3D printing can replicate real-world manufacturing geometry for visualization and fitting tests.

After printing, the surface was fine-polished and sprayed with silver paint, giving it a uniform metallic sheen close to cast aluminum. The finish not only enhances visual realism but also provides a smooth tactile texture, making it ideal for trade shows, engineering demonstrations, and investor presentations.

Quality Evaluation

The print quality is excellent – layer lines are barely visible even in curved and recessed areas. Sharp edges and circular features remain well-defined, showing that the dimensional fidelity of the print is high. The polishing and coating process further refined the surface, giving it a professional and near-production-grade appearance.

Upon close inspection, a few subtle surface textures hint at the model’s additive origin, but overall, the finish rivals die-cast prototypes. The coating’s reflectivity and uniform tone add depth, enhancing the perception of real metal.

Manufactured by FacFox

Such models are widely used in automotive R&D, design verification, and exhibition displays, allowing engineers and clients to visualize internal layouts and external assembly relationships before tooling production begins.

This transmission housing model was built by FacFox using advanced industrial 3D printing technology, then post-processed to achieve a metallic finish.At FacFox, we specialize in producing high-precision device models, automotive components, and industrial prototypes with customizable surface treatments – from matte textures to metallic coatings.

Whether you need visual prototypes, assembly mock-ups, or fully functional test parts, our team can help bring your design to life with speed and precision.Visit FacFox.com to start your project or consult our engineers for a tailored quote.

Solution

- Step 1: File preparation. The CAD model was received, checked for printability, and adjusted for proper wall thickness and details.

- Step 2: Orientation and slicing. The model was oriented to minimize supports and ensure surface accuracy, then sliced with fine resolution settings.

- Step 3: 3D printing. The part was printed on an industrial system to capture complex internal and external geometries with high dimensional fidelity.

- Step 4: Cleaning and post-curing. Residual powder or resin was removed, and the part was fully cured to reach final strength and stability.

- Step 5: Support removal and surface refining. Supports were carefully removed, and rough areas were smoothed through sanding and minor filling.

- Step 6: Polishing. The surface was progressively sanded and polished to achieve a uniform, smooth finish.

- Step 7: Silver coating. A metallic silver paint was evenly sprayed to replicate the look of cast aluminum, followed by light polishing for sheen.

- Step 8: Inspection and assembly. The finished model was inspected for surface quality, assembled if needed, and prepared for display.