- Selective Finishing on Mimaki 3D Printed Full-Color Mermaid Ornament

- SLA 3D Printed Resin Abstract Resin Geometry Sculpture

Material Plastic, Metal

Quantity 2 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

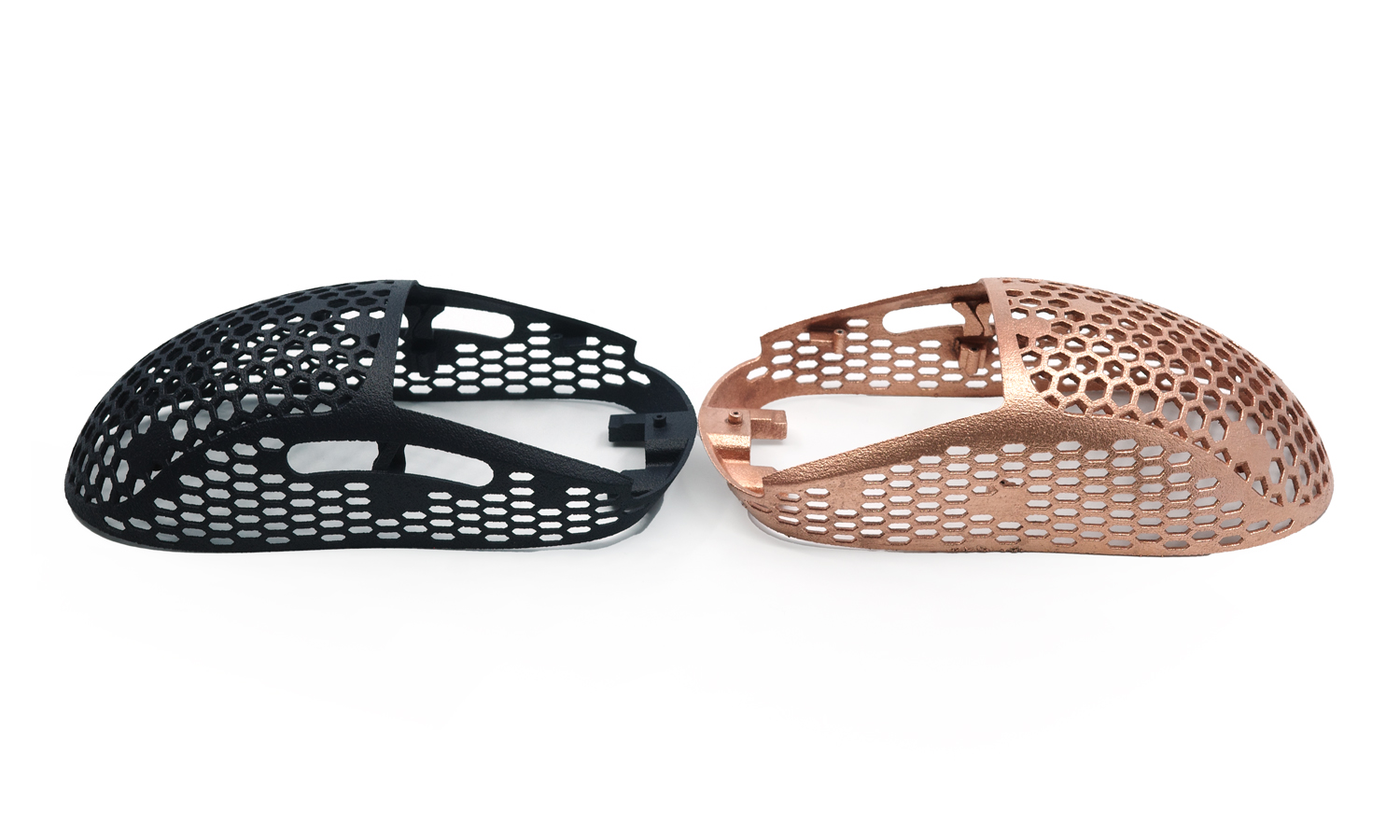

Electroplating 3D-printed parts has long been a challenge, especially when dealing with the complex, porous surfaces of HP Multi Jet Fusion (MJF) nylon. However, these latest samples of a honeycomb mouse shell demonstrate just how far the technology has come. By combining the geometric freedom of MJF with the premium finish of electrolytic copper, we’re seeing a new standard for functional aesthetics.

Visual and Structural Analysis

The first thing you notice is the metallic character. The plating is impressively continuous across the entire honeycomb lattice. Achieving an even gloss on such complex, perforated geometry-without clogging the hexagonal openings or leaving bare spots on the inner walls-is a technical feat. While the characteristic MJF “grain” is still visible beneath the metal, the copper provides a high-end sheen that completely transforms the “plastic” feel of the raw part.

Performance Trade-offs

From a technical standpoint, the detail retention is excellent. Screw bosses and internal mounting points remain sharp and functional, indicating a highly controlled plating thickness. However, the transformation comes with a significant shift in physical properties:

- Weight: The plated shell jumps from 5.5g to 15.7g. While this might be a deterrent for ultra-lightweight competitive gaming, it offers a satisfying “heft” and increased thermal mass for experimental or luxury builds.

- Durability: The copper layer adds surface hardness and wear resistance. However, it also introduces a layer of brittleness; where raw nylon flexes, the copper may micro-crack under extreme stress.

Ultimately, these samples prove that MJF nylon and electrolytic copper are a viable pairing for complex geometries. It is a compelling proof-of-concept for designers looking to bridge the gap between additive manufacturing and traditional metal finishes.

Elevate Your Projects with FacFox

If you are looking to push the boundaries of 3D printing, FacFox offers professional-grade MJF printing and advanced electroplating services to bring your visions to life. Whether you need the lightweight strength of Nylon 12 or the striking aesthetic of a copper, gold, or chrome finish, FacFox provides the technical expertise to ensure your complex geometries are plated with precision. Visit FacFox today to explore our comprehensive finishing options and get an instant quote for your next custom project.

Solution