- Castable Wax and Silver Prototypes of Commemorative Diorama Ring

- AI-Generated 3D Printed Full-color Wedding Miniatures

Material Metal

Quantity 2 pcs

Price Range $100-1,000

Lead Time 3 workdays

Gallery

About Project

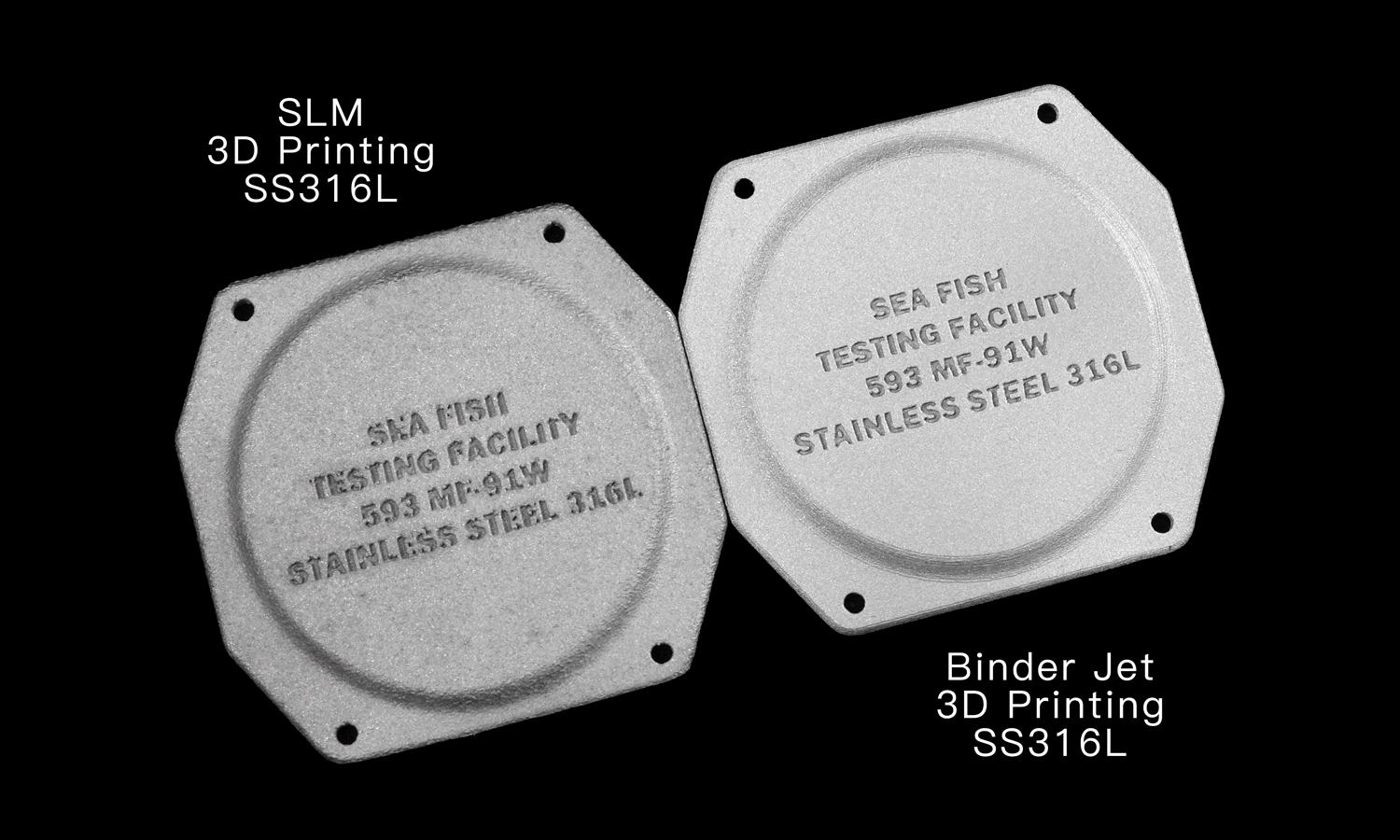

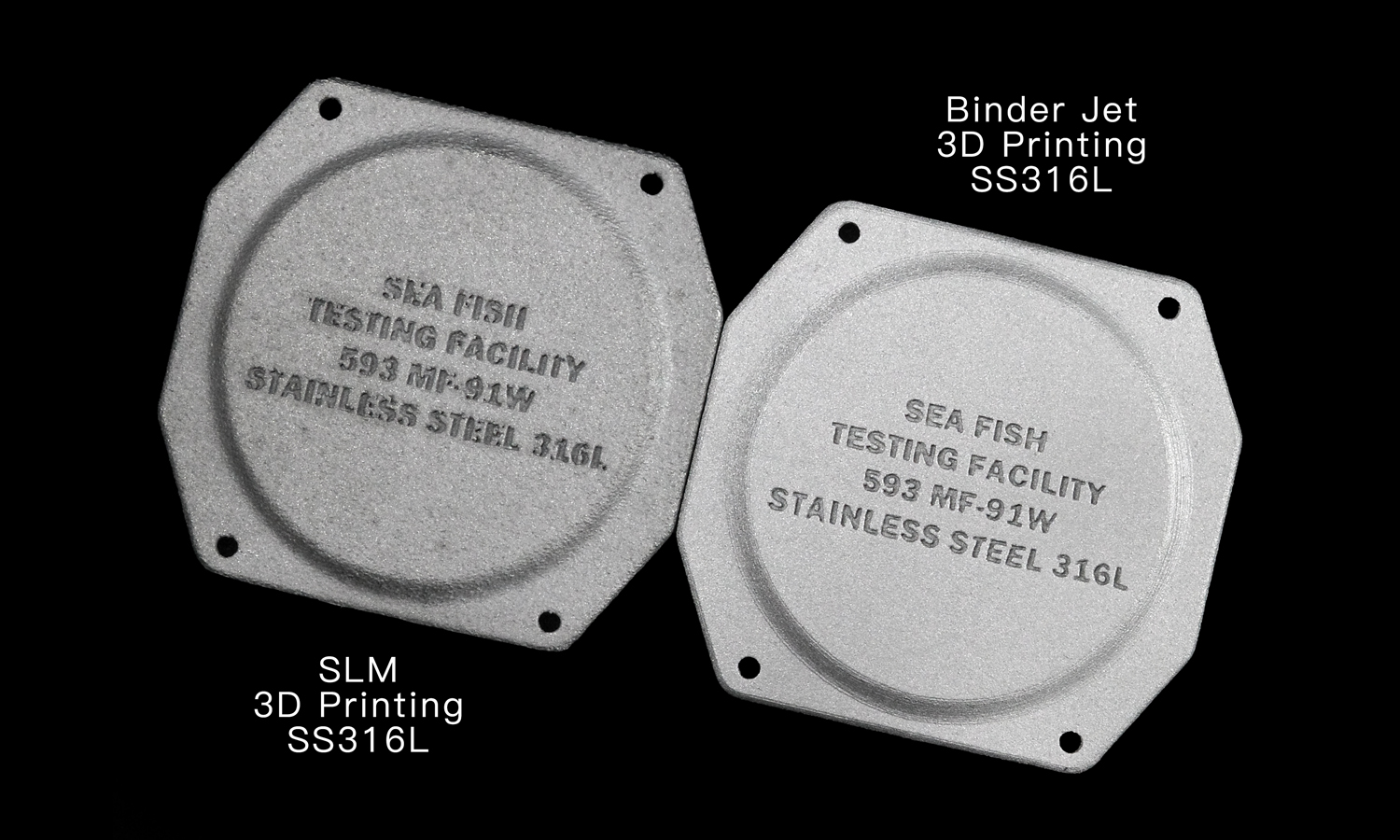

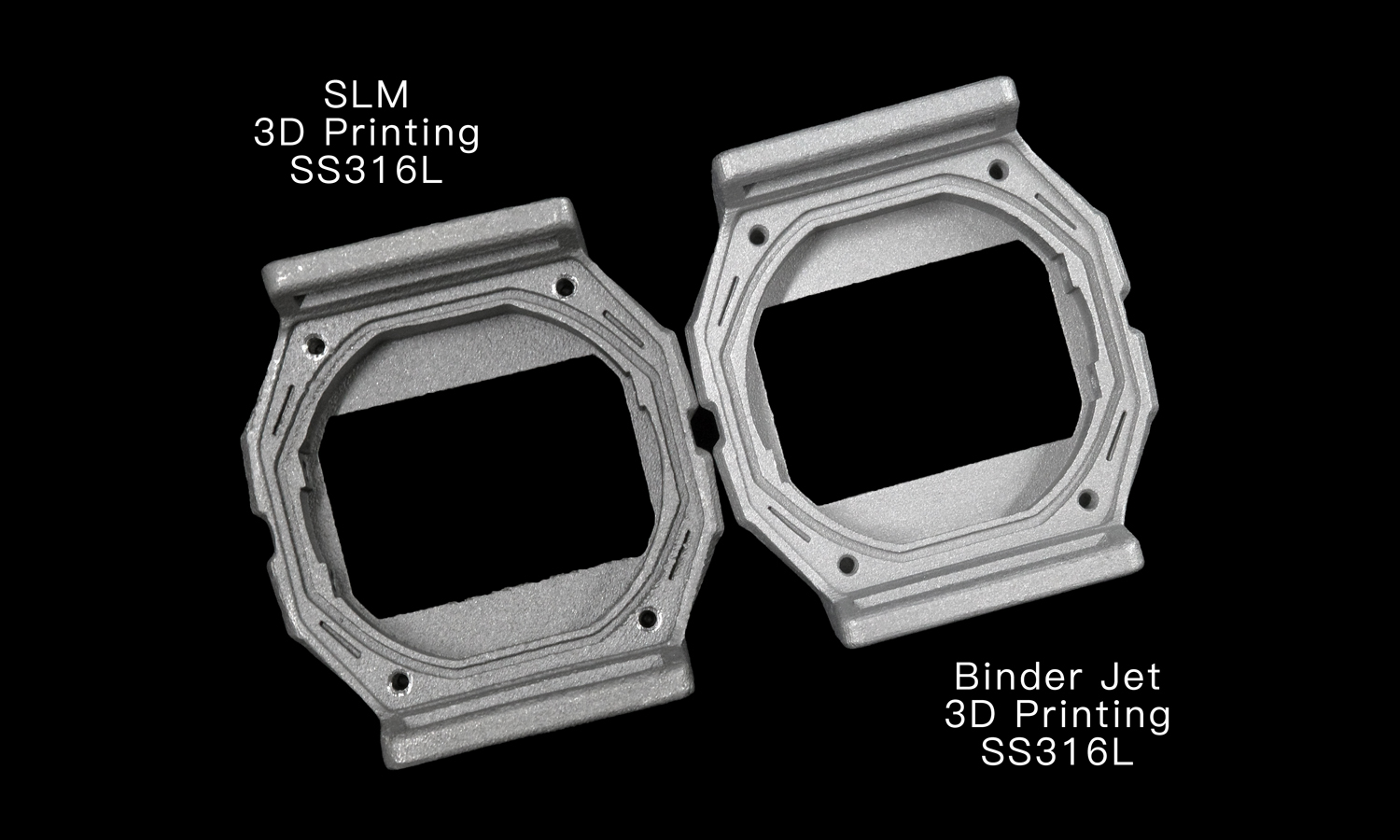

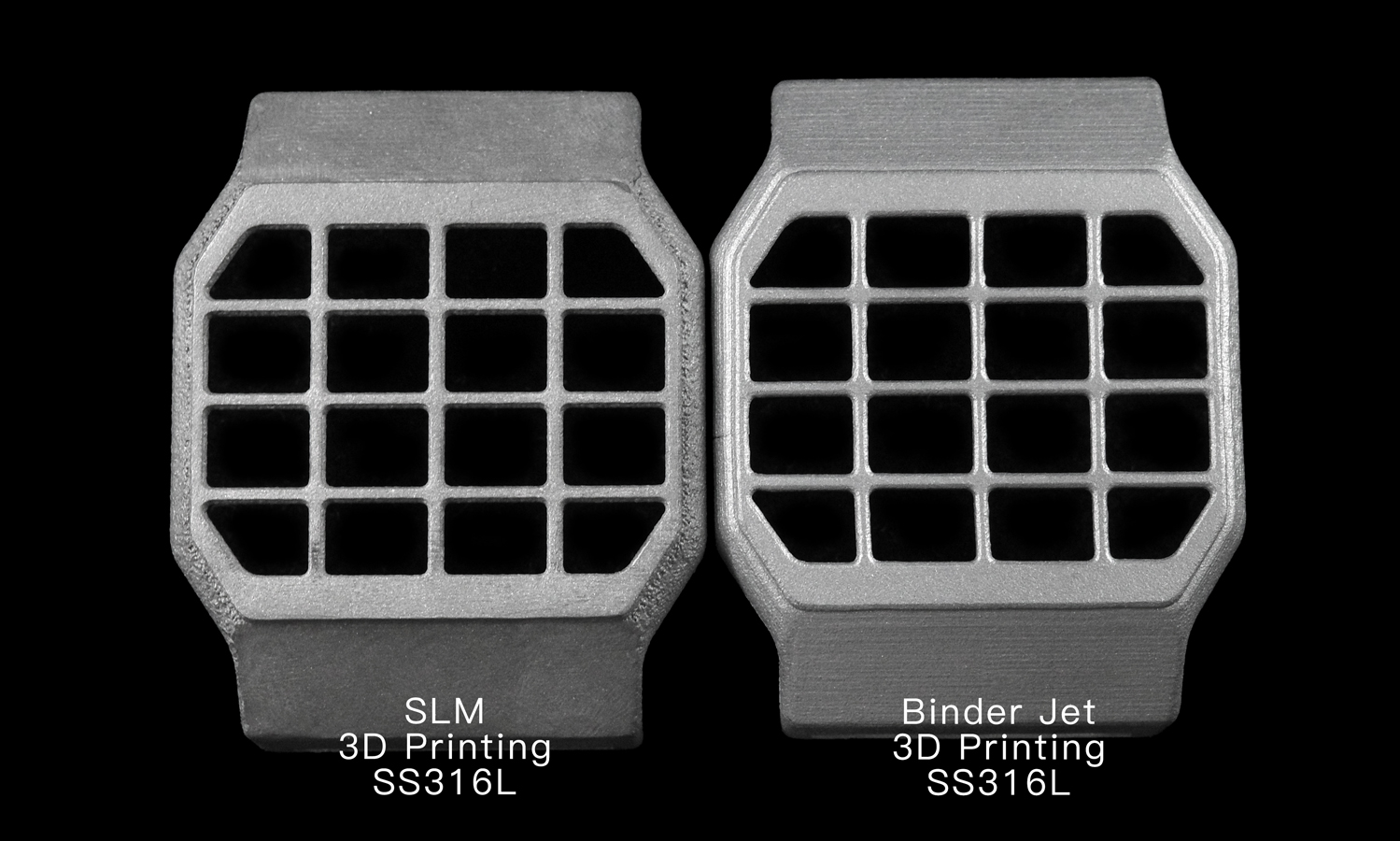

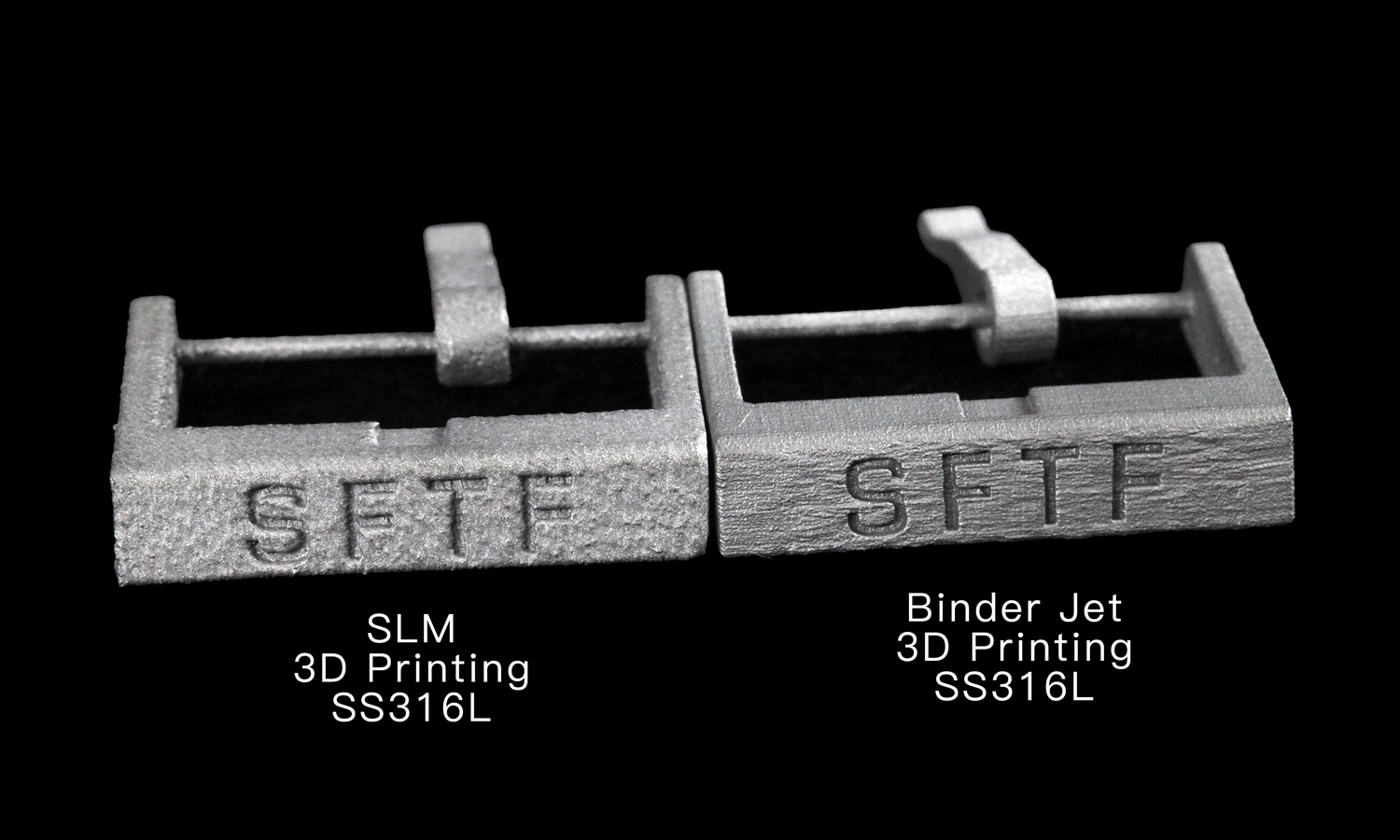

When it comes to stainless steel 316L watch cases, both Selective Laser Melting (SLM) and Binder Jetting offer unique advantages – but they tell very different stories in texture, precision, and visual appeal. FacFox produced the same watch case design using both technologies to evaluate their performance side by side.

Visual Comparison

Under close inspection, both prototypes reveal their distinctive process signatures:

- SLM SS316L (left):The part presents a rougher and darker metallic surface, with visible granularity on the frame edges and softened decorative grooves. However, the lug area shows surprisingly fine fusion and uniformity – evidence of localized melt optimization. Overall, it feels dense and industrial, yet raw.

- Binder Jet SS316L (right):The watch case features a bright and uniform matte finish, with clean lettering, sharper grooves, and evenly distributed texture. Subtle layer lines are visible on certain flat surfaces, but the overall visual consistency is superior. The aesthetic is refined, balanced, and closer to production quality.

Across multiple geometries – backplate, frame, and lug – a clear pattern emerges:SLM excels in density and mechanical strength, while Binder Jetting wins in surface elegance and dimensional uniformity.

Detailed Observations

| Feature | SLM SS316L | Binder Jet SS316L |

|---|---|---|

| Surface Texture | Rough, grainy fusion marks | Fine, powdery matte surface |

| Layer Lines | Subtle, localized melt bands | Slight but uniform banding |

| Lettering & Details | Incomplete or softened | Fully legible, slight distortion |

| Lug Surface | Smooth, metallic | Visible thin layer lines |

| Frame Edges | Coarse granularity | Clean and uniform |

| Tone & Reflectivity | Dark metallic gray | Silvery matte |

| Overall Impression | Strong, functional prototype | Refined, display-ready model |

Conclusion

The test reveals how Binder Jet SS316L offers a visually smoother, more uniform matte finish suitable for display prototypes and luxury aesthetics, while SLM SS316L provides higher density and mechanical reliability ideal for functional testing and end-use components.

In applications like watchmaking, where both look and performance matter, combining the two approaches – prototyping with Binder Jet, validating with SLM – can achieve the best of both worlds.

FacFox Metal 3D Printing Services

FacFox offers a full range of metal additive manufacturing solutions, including SLM, Binder Jetting, DMLS, and DED technologies, serving both functional engineering and high-end design applications.From rapid prototyping to small-batch production in stainless steel, titanium, aluminum, copper, and Inconel, our team provides expert guidance through design optimization, printing, and post-processing.

Solution

- Step 1:The identical 3D model of a stainless-steel watch case was prepared and optimized separately for SLM and Binder Jetting workflows.

- Step 2:For the SLM build, stainless steel 316L powder was selectively melted layer by layer with a high-energy laser, forming a dense metallic structure.

- Step 3:For the Binder Jet build, a liquid binder was deposited to bond stainless-steel powder particles layer by layer. The green part was then sintered to achieve full metallization.

- Step 4:Both prints were depowdered, cleaned, and subjected to identical shot-blasting treatments for a fair surface comparison.

- Step 5:Each prototype was photographed under uniform lighting to evaluate reflectivity, texture, and detail fidelity.