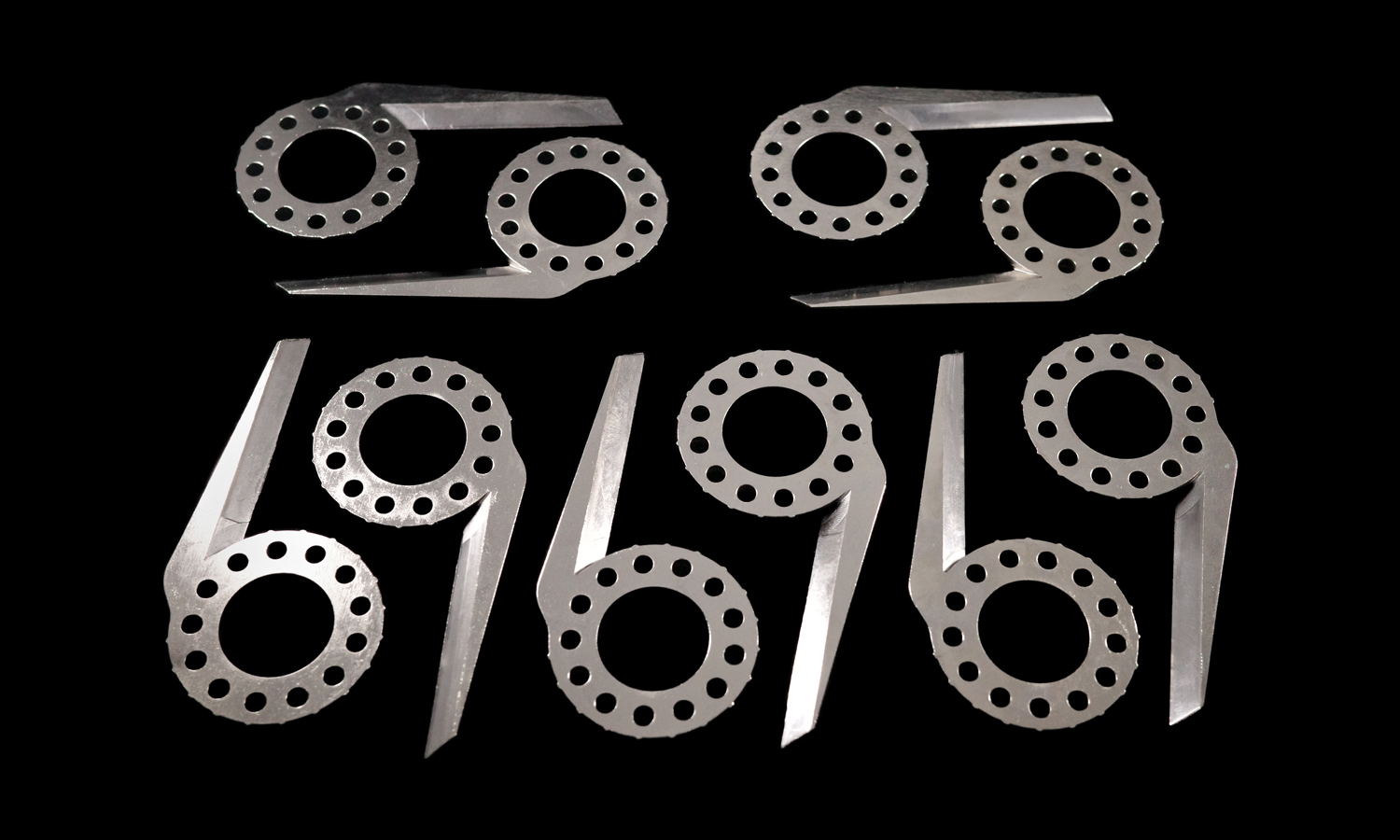

- CNC Milled POM Spur Gear Custom Plastic Flywheel

- CNC Milled Threaded Chain Pin Aluminum Slider Pin Shaft Kit

Material Metal

Quantity 10 pcs

Price Range $100-1,000

Lead Time 10 workdays

Gallery

About Project

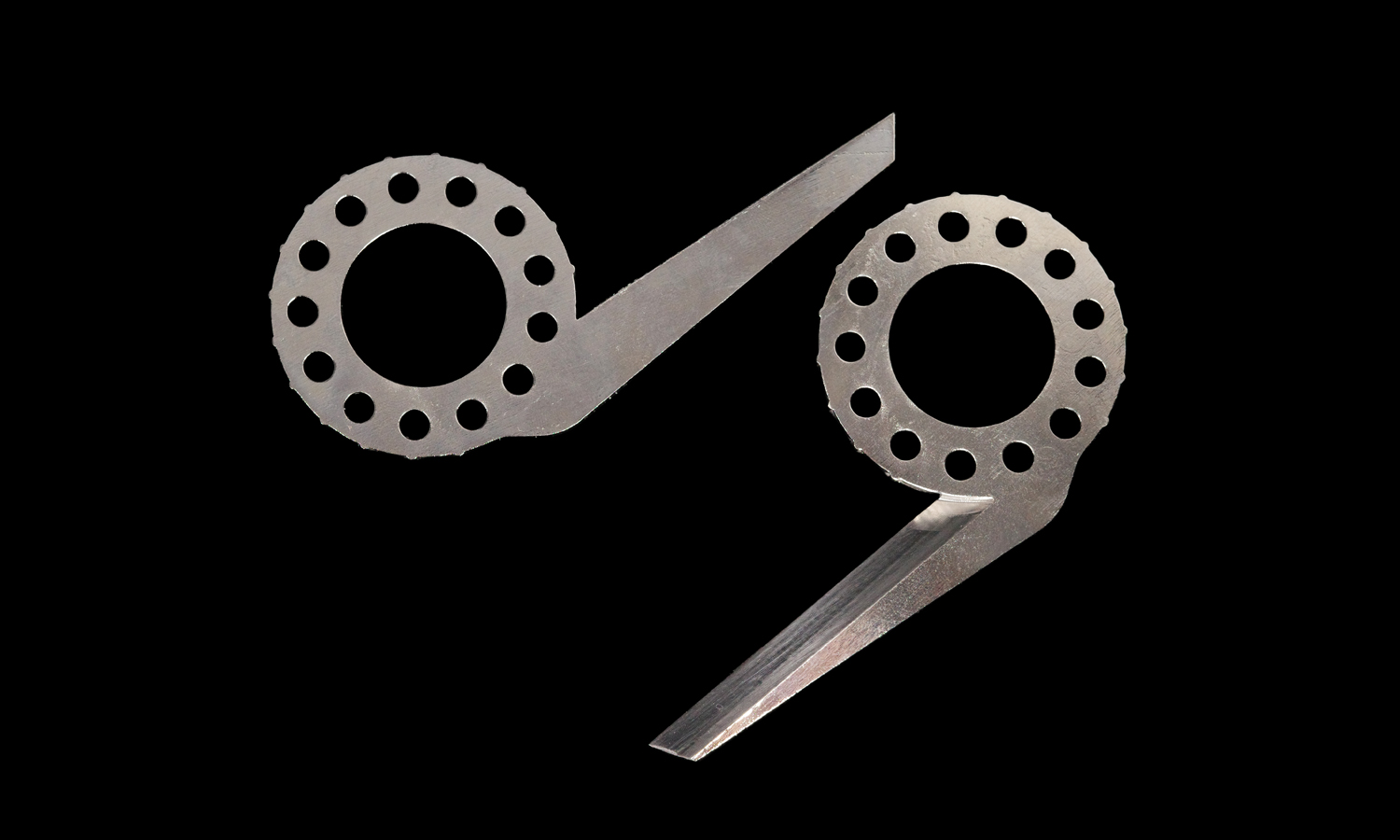

The blades we made are made with D2 tooling steel and heat-treated to 60 HRC hardness. They have been sharpened and electroplated with nickel. The nickel plating provides a layer of protection against corrosion and wear.

D2 tooling steel is a high carbon, high chromium tool steel that is known for its excellent abrasion resistance. It is also known as semi-stainless steel because of its high chromium content, which is not enough to provide corrosion resistance. The hardness of D2 tooling steel can reach 60+HRC after heat treatment.

If youŌĆÖre looking for CNC services, FacFox offers a wide range of services including CNC milling and turning. We specialize in high-precision machining and can help you with your manufacturing needs. You can visit their website at https://www.facfox.com/ for more information.

Solution

- Step 1: The CAD model was examined and transformed into a CNC-compatible format with the software AutoCAD.

- Step 2: A most suitable type of CNC machine was chosen according to the complexity of the product design and the cost of the workpiece.

- Step 3: Certain operations were configured and the G-codes were input on the machine. The workpiece was mounted on the machine as well.

- Step 4: The workpiece got shaped and the holes were drilled automatically. It would be inspected during and after the machining process for quality assurance.

- Step 5: The blades were then heat-treated to HRC 60 to increase their hardness. After heat treatment, the blades were sharpened to ensure that they were sharp and ready for use.

- Step 6: The part was degreased and manually cleaned, and then placed into a preheated nickle plating vat for minutes.