Gallery

About Project

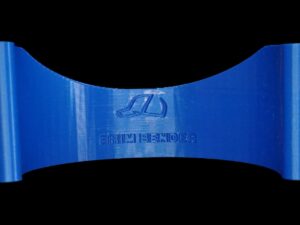

FacFox is proud to showcase our latest CNC machining masterpiece: a Bluetooth speaker enclosure that combines sleek design with exceptional precision. This meticulously crafted enclosure features a cylindrical shape, a vibrant red anodized finish, and a hollow interior for optimal sound quality.

One of the standout features of this enclosure is the intricate raised and sunken letters that we’ve successfully machined onto its surface. These delicate details add a touch of sophistication and personalization, setting it apart from ordinary speaker enclosures.

The enclosure’s tapered base ensures stability, while the front panel provides dedicated spaces for the volume control knob and brand nameplate. The top panel is equipped with multiple holes to accommodate essential features such as charging, USB connectivity, and more.

Experience the power of precision with FacFox. Our CNC machining expertise allows us to create custom enclosures with unparalleled detail and accuracy. Contact us today to discuss your project and discover how we can help you elevate your product to new heights.

Solution

- Step 1: Design and Modeling. The initial design for the Bluetooth speaker enclosure was created using computer-aided design (CAD) software.

- Step 2: Material Selection. Aluminum was chosen as the primary material for the enclosure due to its lightweight, durability, and excellent heat dissipation properties.

- Step 3: CNC Machining. A CNC milling machine was used to precisely shape the aluminum block into the desired cylindrical form. The intricate raised and sunken letters were also machined using the CNC machine.

- Step 4: Anodizing. The aluminum enclosure was anodized to create a protective oxide layer on its surface, enhancing its durability, corrosion resistance, and aesthetic appeal. The red color was achieved through a specific anodizing process.

- Step 5: Finishing. Any necessary finishing touches, such as polishing or deburring, were performed to ensure a smooth and high-quality finish.

- Step 6: Quality Inspection. The finished enclosures were subjected to rigorous quality inspection to verify that they met the specified dimensions, tolerances, and surface finish requirements.