Material Plastic

Quantity 1 pcs

Price Range $1-100

Lead Time 1 workdays

Gallery

About Project

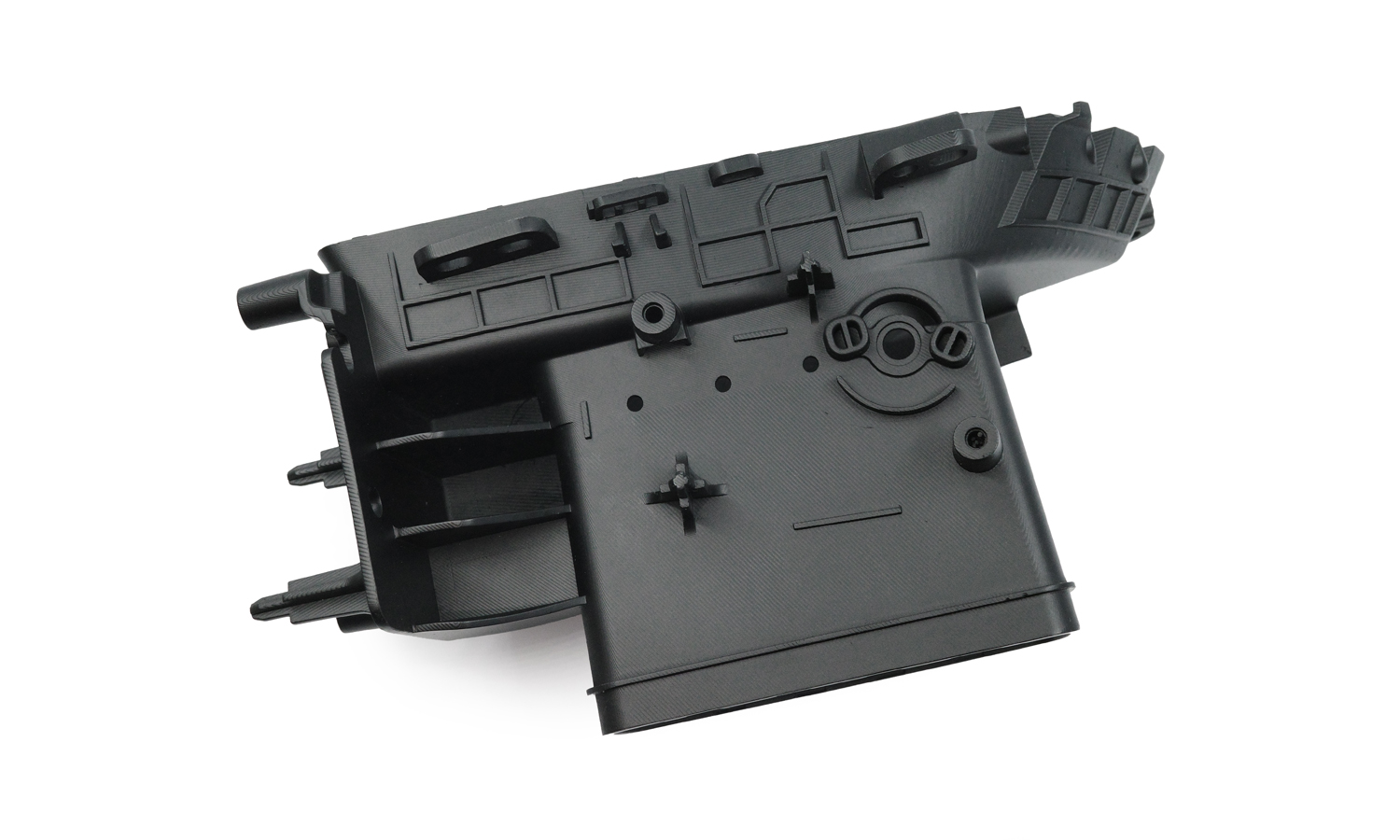

When it comes to automotive development, speed and precision matter. Our client needed a robust prototype of a complex HVAC duct-full of internal channels, multiple mounting features, and intricate geometry that would normally require a mold. Instead of waiting weeks and spending thousands on tooling, they turned to FacFox for a fast, functional 3D-printed solution.

Why Flashforge Tough Filament?

Flashforge Tough is an engineering-grade FDM material designed for strong, impact-resistant parts. For an HVAC duct prototype that must withstand handling, assembly tests, and repeated fit checks, it offered the perfect balance of:

- High toughness and durability

- Improved flexibility over standard PLA

- Better heat resistance and long-term stability

- Excellent dimensional accuracy for assemblies

This allowed the duct to be test-fitted inside a dashboard environment, evaluated for airflow and mechanical interfaces, and iterated quickly when design changes were required.

Project Highlights

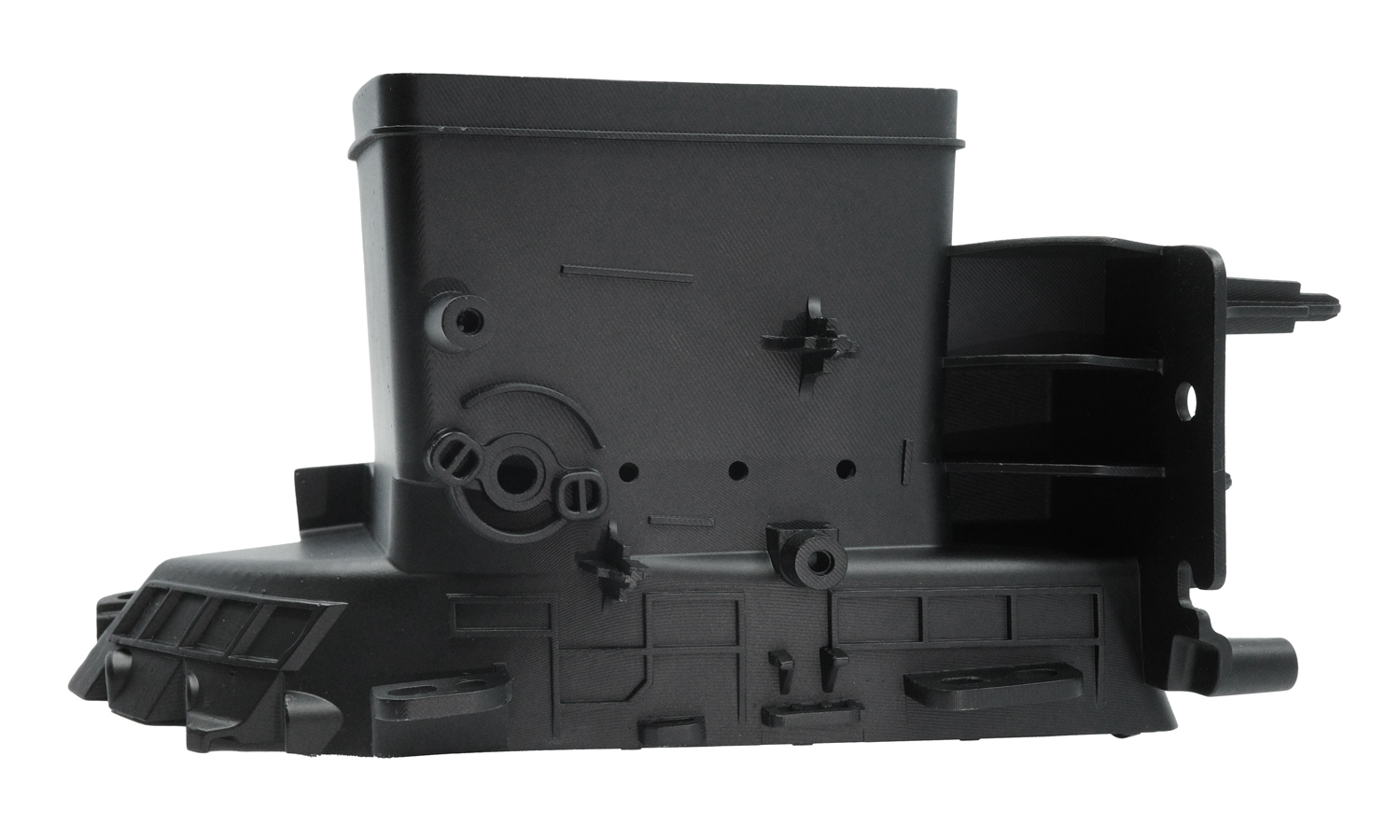

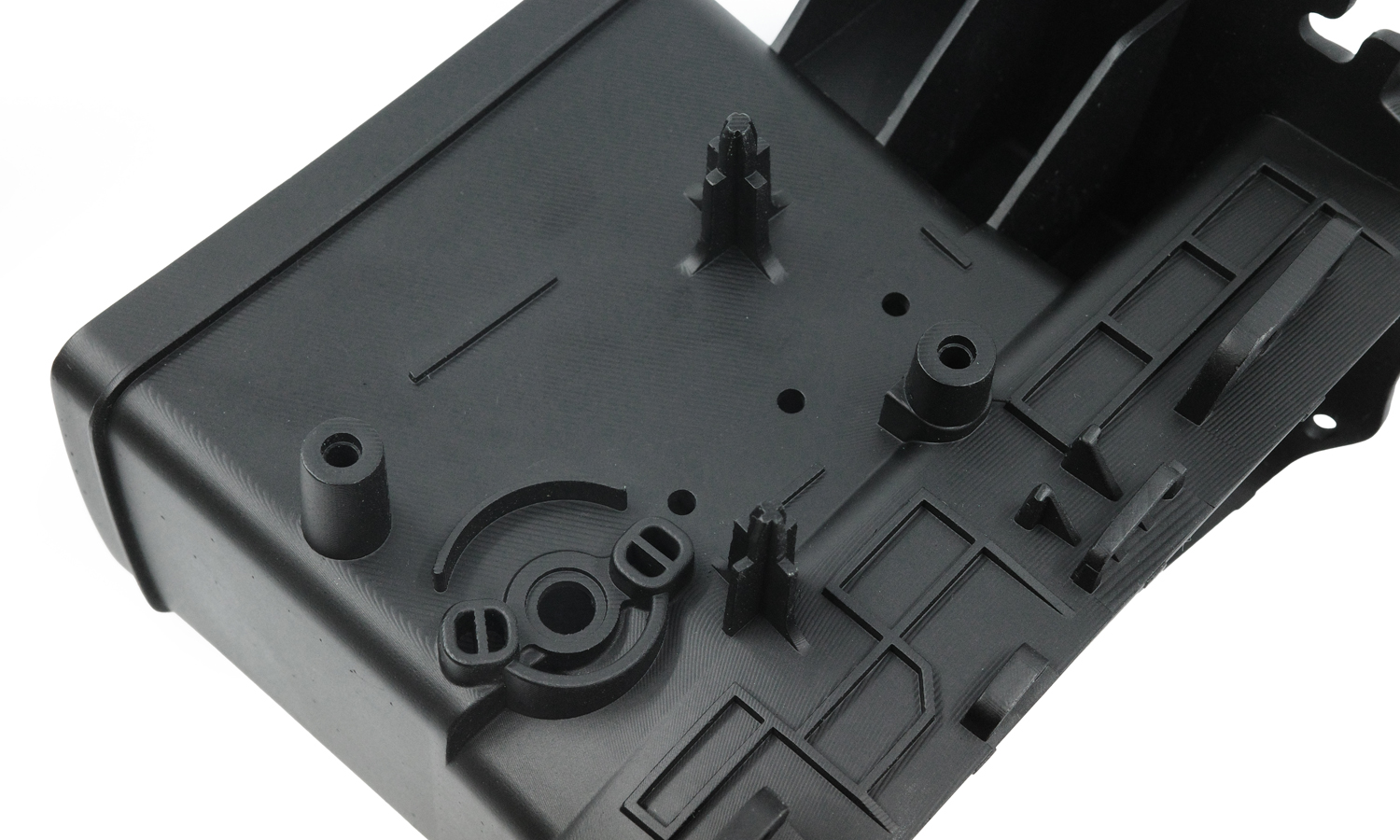

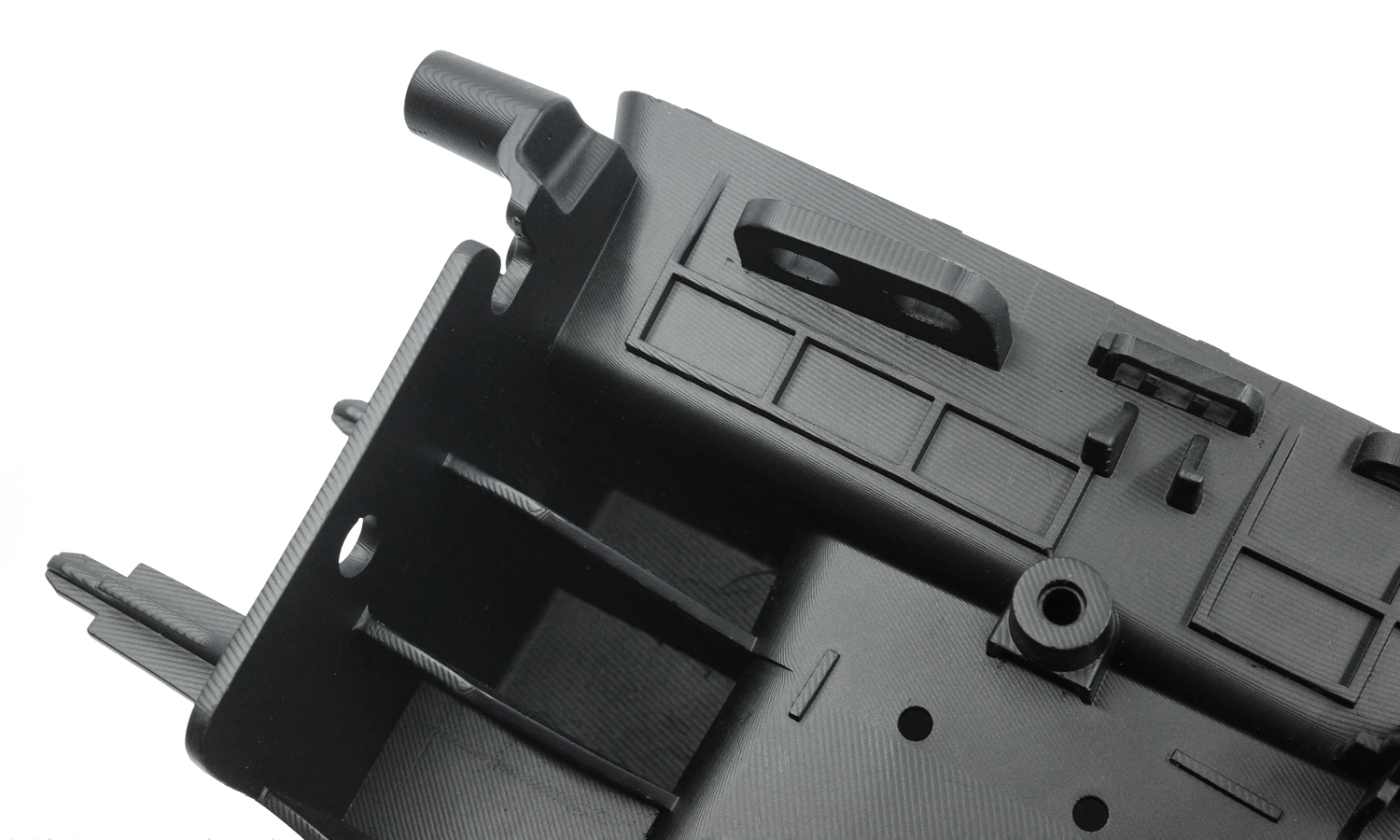

The duct’s complex architecture-multiple ports, snap-features, reinforcement ribs, and curved internal passages-was printed as a single integrated structure. With FDM and Flashforge Tough, we achieved:

- Clean, uniform surface quality

- Strong inter-layer bonding

- Accurate alignment of screw bosses and mounting tabs

- A fully functional prototype ready for engineering validation

No molds, no long lead times-just fast, reliable geometry straight from CAD to reality.

Why Choose FacFox for Projects Like This?

At FacFox, we specialize in turning challenging industrial designs into production-ready prototypes. Whether you need a one-off test part or a batch of engineering samples, our FDM, SLS, SLA, MJF, WJP, and full-color Mimaki printers let you choose the manufacturing method that fits your needs.

For automotive components in particular, we offer:

- Engineering-grade materials (Tough PLA, ABS, Nylon, Nylon-GF, TPU, etc.)

- Large-size printing capabilities

- Tight tolerances and repeatability

- Professional finishing and inspection

From concept to installation test, we help engineers iterate faster and reduce development cycles.

Solution

- Step 1: 3D Model Preparation. The HVAC duct’s CAD model was inspected, optimized, and exported as a watertight STL file. All thin walls, overhangs, and mechanical interfaces were checked to ensure printability.

- Step 2: Slicing Configuration. The STL file was imported into slicing software, where layer height, infill density, print temperature, and support structures were configured. The printing profile for Flashforge Tough filament was applied to ensure strength and dimensional stability.

- Step 3: FDM 3D Printing. The part was printed on an FDM machine using Flashforge Tough filament. The layers were deposited sequentially, and the geometry was built upward from the base. The printing process was completed in several hours due to the part’s large size and structural complexity.

- Step 4: Support Removal. After printing, the part was cooled to room temperature, removed from the build plate, and all support structures were carefully detached. Tools were used where necessary to ensure that no critical features were damaged.

- Step 5: Surface Finishing. The printed surface was cleaned, trimmed, and lightly sanded where needed. Edges were deburred, and residual filament artifacts were smoothed to provide a neat and uniform appearance.

- Step 6: Dimensional Inspection. Key mounting points, ports, and interfaces were measured to verify dimensional accuracy. The part was inspected for warping, layer consistency, and overall structural integrity.