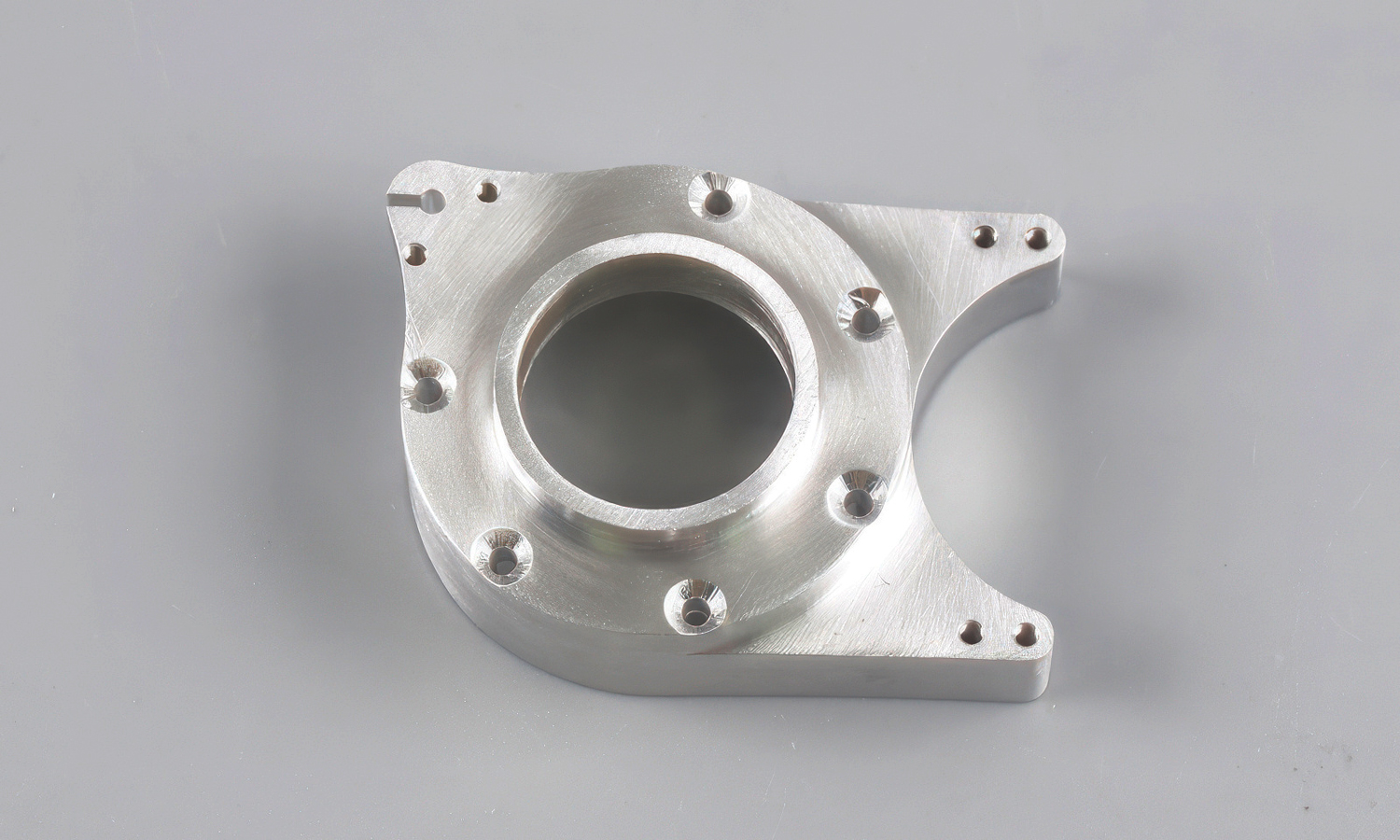

- CNC Milled Al7075 Racing Front Disc Guard

- CNC Milled Aluminum Anodized Red Bluetooth Speaker Prototype

Gallery

About Project

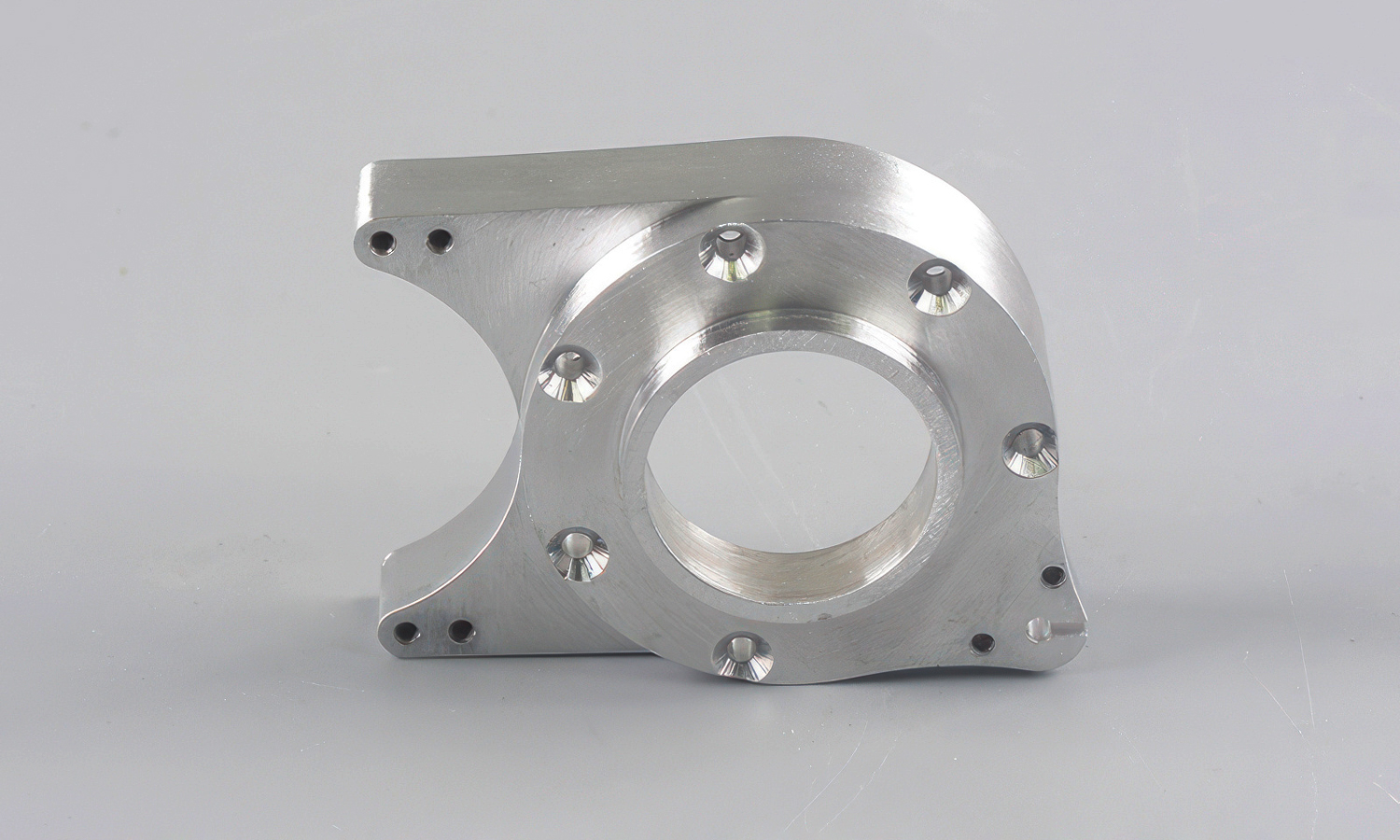

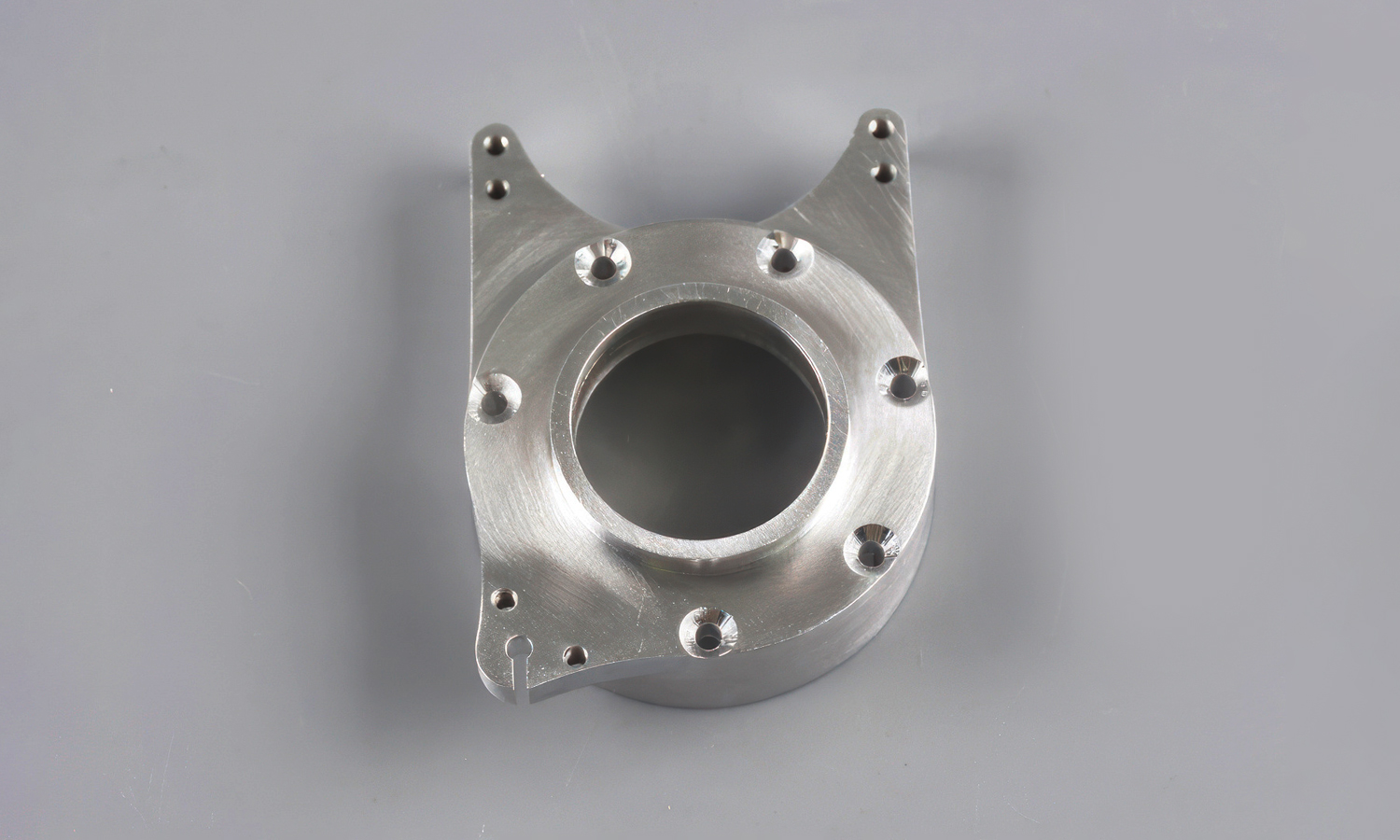

CNC milling is a versatile manufacturing process capable of creating intricate and precise components. One excellent example is the rear brake caliper adapter plate. This essential part allows for the installation of larger, more powerful calipers, enhancing braking performance and safety.

The precision and accuracy of CNC milling ensure a perfect fit between the adapter plate and the caliper, guaranteeing optimal performance. Additionally, CNC machining enables the creation of complex geometries and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods.

By choosing CNC milling for your rear brake caliper adapter plate, you can benefit from:

- Customization: Tailored designs to fit specific vehicle models and caliper types.

- Precision: Accurate dimensions and tolerances for optimal performance.

- Efficiency: Streamlined production process for faster turnaround times.

- Durability: High-quality materials and robust construction for long-lasting reliability.

If you’re looking to upgrade your vehicle’s braking system and require a custom-made rear brake caliper adapter plate, CNC milling is the ideal solution. With its ability to create complex parts with precision and efficiency, CNC machining can help you achieve your desired performance goals.

FacFox is a leading provider of CNC milling services for the automotive industry. Our state-of-the-art equipment and experienced team can deliver high-quality custom parts to meet your exact specifications. Contact us today to discuss your project and learn how FacFox can help you elevate your automotive performance.

Solution

- Step 1: Design and CAD Modeling. The initial step involves creating a detailed 3D CAD model of the rear brake caliper adapter plate. This model specifies the dimensions, tolerances, and intricate features required for the part.

- Step 2: Material Selection. A suitable material, such as high-strength steel, is chosen based on the desired strength, durability, and weight requirements.

- Step 3: CNC Machining Setup. The CAD model is transferred to the CNC milling machine, where the necessary tools and fixtures are set up to accurately process the material.

- Step 4: Rough Machining. The material is initially shaped to a rough approximation of the final part using larger cutting tools. This stage removes excess material and prepares the workpiece for subsequent finishing operations.

- Step 5: Finishing Machining. Smaller cutting tools are used to refine the surface finish and achieve the precise dimensions and tolerances specified in the CAD model. This process involves removing material in small increments to create the desired contours and features.

- Step 6: Inspection and Quality Control. The finished adapter plate is carefully inspected to ensure that it meets all the specified requirements, including dimensions, tolerances, and surface finish. Quality control measures are implemented to identify and correct any defects.

- Step 7: Finishing Touches. Optional finishing treatments, such as heat treatment or coating, may be applied to enhance the part’s properties or appearance.

- Step 8: Packaging and Shipping. The completed adapter plate is packaged securely and shipped to the customer for installation.